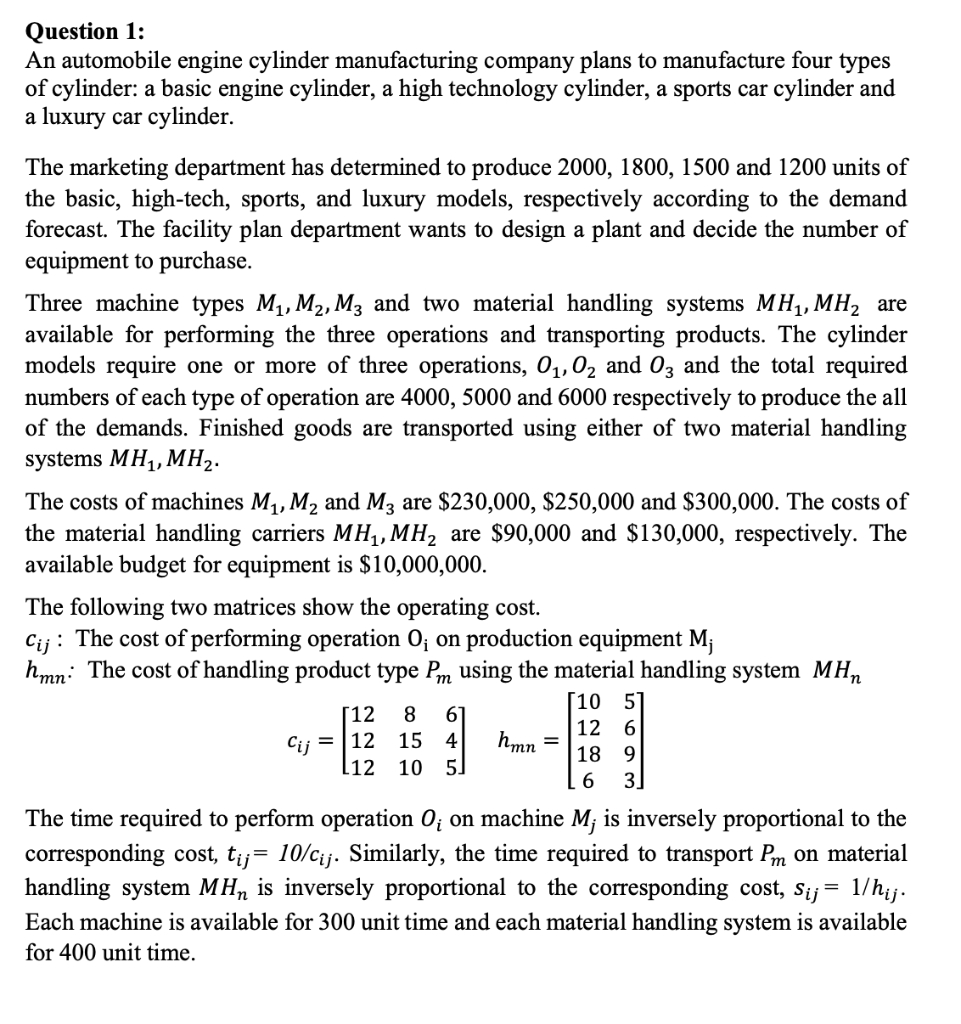

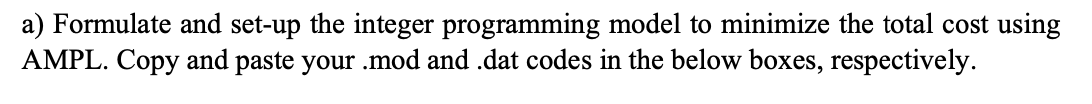

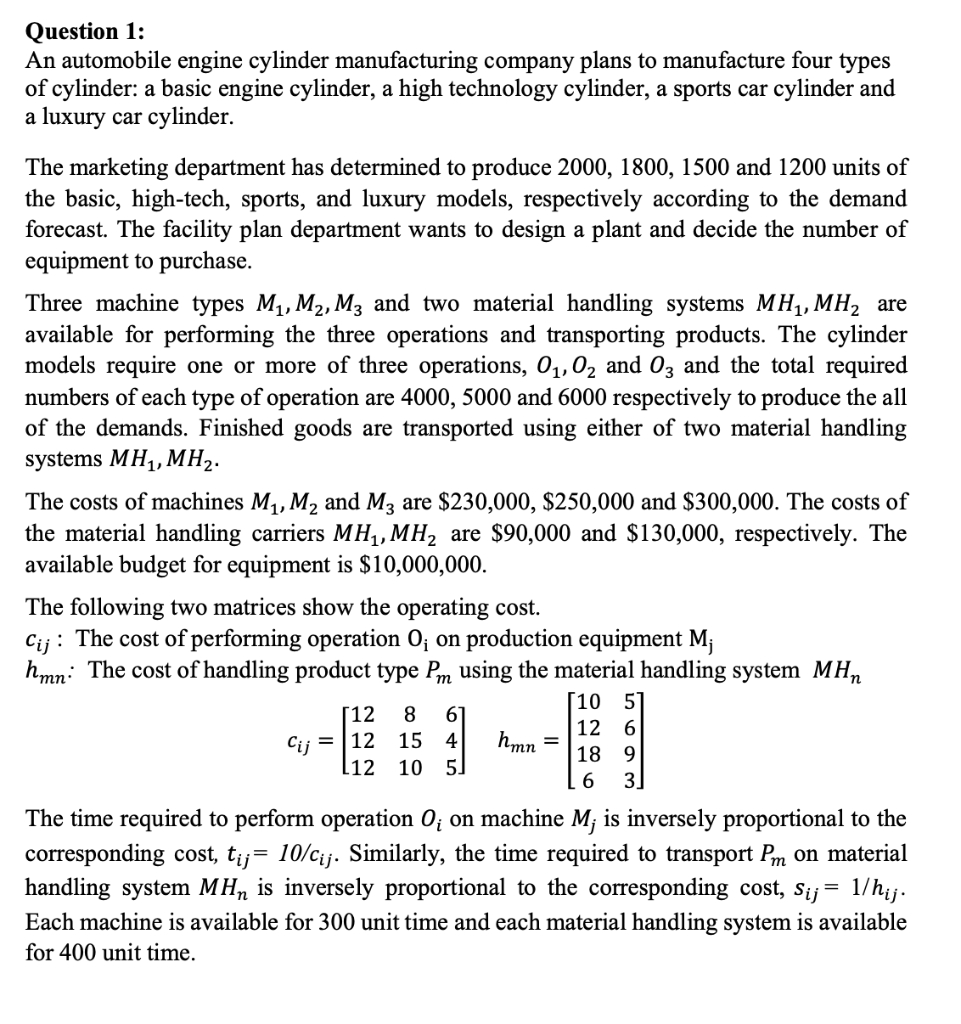

Question 1: An automobile engine cylinder manufacturing company plans to manufacture four types of cylinder: a basic engine cylinder, a high technology cylinder, a sports car cylinder and a luxury car cylinder. The marketing department has determined to produce 2000, 1800, 1500 and 1200 units of the basic, high-tech, sports, and luxury models, respectively according to the demand forecast. The facility plan department wants to design a plant and decide the number of equipment to purchase. Three machine types M1, M2,M3 and two material handling systems MH1, MH2 are available for performing the three operations and transporting products. The cylinder models require one or more of three operations, 01,02 and 03 and the total required numbers of each type of operation are 4000, 5000 and 6000 respectively to produce the all of the demands. Finished goods are transported using either of two material handling systems MH1, MH2. The costs of machines M1, M2 and M3 are $230,000, $250,000 and $300,000. The costs of the material handling carriers MH,MH2 are $90,000 and $130,000, respectively. The available budget for equipment is $10,000,000. The following two matrices show the operating cost. Cij: The cost of performing operation 0; on production equipment M; hmn: The cost of handling product type Pm using the material handling system Min [10 5 [12 12 15 4 18 9 L12 10 6 3 The time required to perform operation 0; on machine M; is inversely proportional to the corresponding cost, tij= 10/cij. Similarly, the time required to transport Pm on material handling system MHn is inversely proportional to the corresponding cost, Sij = 1/hij. Each machine is available for 300 unit time and each material handling system is available for 400 unit time. 8 6 6 Cij = 12 = hmn 5. a) Formulate and set-up the integer programming model to minimize the total cost using AMPL. Copy and paste your .mod and .dat codes in the below boxes, respectively. b) What is the optimal objective value? What is the optimal quantity of each production and handling equipment? The optimal objective value: Click or tap here to enter text. The optimal solution is (M1,M2,M3,MH1,MH2) = Click or tap here to enter text. Question 1: An automobile engine cylinder manufacturing company plans to manufacture four types of cylinder: a basic engine cylinder, a high technology cylinder, a sports car cylinder and a luxury car cylinder. The marketing department has determined to produce 2000, 1800, 1500 and 1200 units of the basic, high-tech, sports, and luxury models, respectively according to the demand forecast. The facility plan department wants to design a plant and decide the number of equipment to purchase. Three machine types M1, M2,M3 and two material handling systems MH1, MH2 are available for performing the three operations and transporting products. The cylinder models require one or more of three operations, 01,02 and 03 and the total required numbers of each type of operation are 4000, 5000 and 6000 respectively to produce the all of the demands. Finished goods are transported using either of two material handling systems MH1, MH2. The costs of machines M1, M2 and M3 are $230,000, $250,000 and $300,000. The costs of the material handling carriers MH,MH2 are $90,000 and $130,000, respectively. The available budget for equipment is $10,000,000. The following two matrices show the operating cost. Cij: The cost of performing operation 0; on production equipment M; hmn: The cost of handling product type Pm using the material handling system Min [10 5 [12 12 15 4 18 9 L12 10 6 3 The time required to perform operation 0; on machine M; is inversely proportional to the corresponding cost, tij= 10/cij. Similarly, the time required to transport Pm on material handling system MHn is inversely proportional to the corresponding cost, Sij = 1/hij. Each machine is available for 300 unit time and each material handling system is available for 400 unit time. 8 6 6 Cij = 12 = hmn 5. a) Formulate and set-up the integer programming model to minimize the total cost using AMPL. Copy and paste your .mod and .dat codes in the below boxes, respectively. b) What is the optimal objective value? What is the optimal quantity of each production and handling equipment? The optimal objective value: Click or tap here to enter text. The optimal solution is (M1,M2,M3,MH1,MH2) = Click or tap here to enter text