Answered step by step

Verified Expert Solution

Question

1 Approved Answer

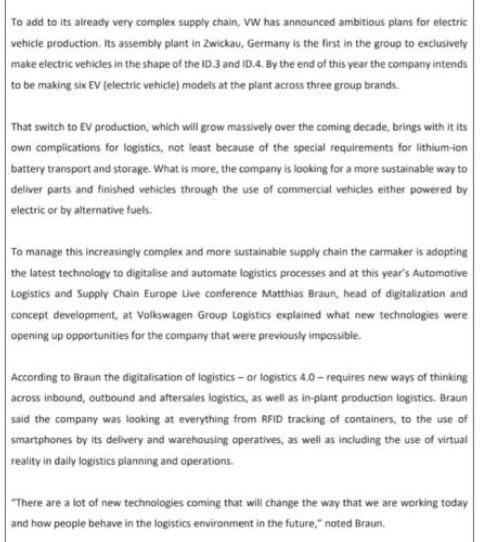

To add to its already very complex supply chain, VW has announced ambitious plans for electric vehicle production. Its assembly plant in Zwickau, Germany

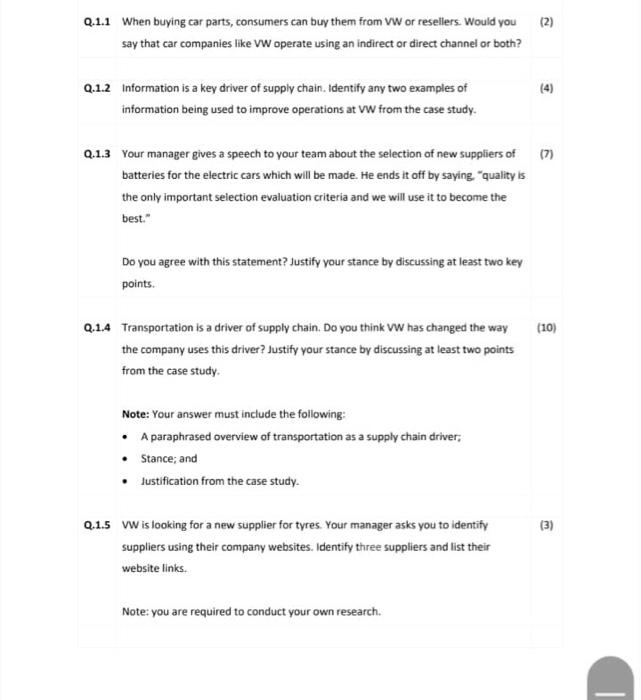

To add to its already very complex supply chain, VW has announced ambitious plans for electric vehicle production. Its assembly plant in Zwickau, Germany is the first in the group to exclusively make electric vehicles in the shape of the ID.3 and ID.4. By the end of this year the company intends to be making six EV (electric vehicle) models at the plant across three group brands. That switch to EV production, which will grow massively over the coming decade, brings with it its own complications for logistics, not least because of the special requirements for lithium-ion battery transport and storage. What is more, the company is looking for a more sustainable way to deliver parts and finished vehicles through the use of commercial vehicles either powered by electric or by alternative fuels. To manage this increasingly complex and more sustainable supply chain the carmaker is adopting the latest technology to digitalise and automate logistics processes and at this year's Automotive Logistics and Supply Chain Europe Live conference Matthias Braun, head of digitalization and concept development, at Volkswagen Group Logistics explained what new technologies were opening up opportunities for the company that were previously impossible. According to Braun the digitalisation of logistics-or logistics 4.0-requires new ways of thinking across inbound, outbound and aftersales logistics, as well as in-plant production logistics. Braun said the company was looking at everything from RFID tracking of containers, to the use of smartphones by its delivery and warehousing operatives, as well as including the use of virtual reality in daily logistics planning and operations. "There are a lot of new technologies coming that will change the way that we are working today and how people behave in the logistics environment in the future," noted Braun. Q.1.1 When buying car parts, consumers can buy them from VW or resellers. Would you (2) say that car companies like VW operate using an indirect or direct channel or both? Q.1.2 Information is a key driver of supply chain. Identify any two examples of information being used to improve operations at VW from the case study. Q.1.3 Your manager gives a speech to your team about the selection of new suppliers of (7) batteries for the electric cars which will be made. He ends it off by saying "quality is the only important selection evaluation criteria and we will use it to become the best." Do you agree with this statement? Justify your stance by discussing at least two key points. Q.1.4 Transportation is a driver of supply chain. Do you think VW has changed the way the company uses this driver? Justify your stance by discussing at least two points from the case study. Note: Your answer must include the following: A paraphrased overview of transportation as a supply chain driver, Stance; and Justification from the case study. Q.1.5 VW is looking for a new supplier for tyres. Your manager asks you to identify suppliers using their company websites. Identify three suppliers and list their website links. Note: you are required to conduct your own research. (10) (3)

Step by Step Solution

★★★★★

3.33 Rating (162 Votes )

There are 3 Steps involved in it

Step: 1

Introduction The case study explores how Volkswagen VW is navigating the complexities of its supply chain particularly in the context of its ambitious plans for electric vehicle EV production The shif...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started