Answered step by step

Verified Expert Solution

Question

1 Approved Answer

QUESTION 1 Match the following terms with their correct definitions. - fourth-party logistics ( 4PL ) - logistics management materials handling - random-location storage -

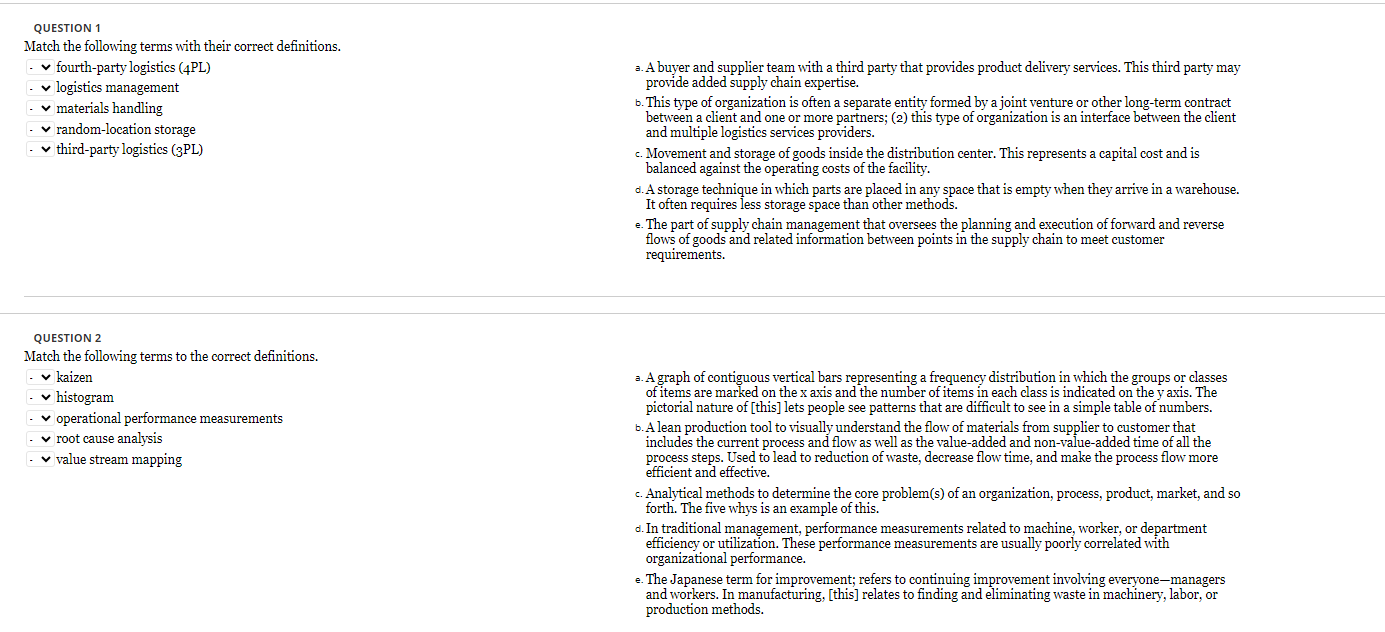

QUESTION 1 Match the following terms with their correct definitions. - fourth-party logistics ( 4PL ) - logistics management materials handling - random-location storage - third-party logistics (3PL) a. A buyer and supplier team with a third party that provides product delivery services. This third party may provide added supply chain expertise. b. This type of organization is often a separate entity formed by a joint venture or other long-term contract between a client and one or more partners; (2) this type of organization is an interface between the client and multiple logistics services providers. c. Movement and storage of goods inside the distribution center. This represents a capital cost and is balanced against the operating costs of the facility. d. A storage technique in which parts are placed in any space that is empty when they arrive in a warehouse. It often requires less storage space than other methods. e. The part of supply chain management that oversees the planning and execution of forward and reverse flows of goods and related information between points in the supply chain to meet customer requirements. QUESTION 2 Match the following terms to the correct definitions. - kaizen - histogram operational performance measurements - root cause analysis - value stream mapping a. A graph of contiguous vertical bars representing a frequency distribution in which the groups or classes of items are marked on the x axis and the number of items in each class is indicated on the y axis. The pictorial nature of [this] lets people see patterns that are difficult to see in a simple table of numbers. b. A lean production tool to visually understand the flow of materials from supplier to customer that includes the current process and flow as well as the value-added and non-value-added time of all the process steps. Used to lead to reduction of waste, decrease flow time, and make the process flow more efficient and effective. c. Analytical methods to determine the core problem(s) of an organization, process, product, market, and so forth. The five whys is an example of this. d. In traditional management, performance measurements related to machine, worker, or department efficiency or utilization. These performance measurements are usually poorly correlated with organizational performance. e. The Japanese term for improvement; refers to continuing improvement involving everyone-managers and workers. In manufacturing, [this] relates to finding and eliminating waste in machinery, labor, or production methods

QUESTION 1 Match the following terms with their correct definitions. - fourth-party logistics ( 4PL ) - logistics management materials handling - random-location storage - third-party logistics (3PL) a. A buyer and supplier team with a third party that provides product delivery services. This third party may provide added supply chain expertise. b. This type of organization is often a separate entity formed by a joint venture or other long-term contract between a client and one or more partners; (2) this type of organization is an interface between the client and multiple logistics services providers. c. Movement and storage of goods inside the distribution center. This represents a capital cost and is balanced against the operating costs of the facility. d. A storage technique in which parts are placed in any space that is empty when they arrive in a warehouse. It often requires less storage space than other methods. e. The part of supply chain management that oversees the planning and execution of forward and reverse flows of goods and related information between points in the supply chain to meet customer requirements. QUESTION 2 Match the following terms to the correct definitions. - kaizen - histogram operational performance measurements - root cause analysis - value stream mapping a. A graph of contiguous vertical bars representing a frequency distribution in which the groups or classes of items are marked on the x axis and the number of items in each class is indicated on the y axis. The pictorial nature of [this] lets people see patterns that are difficult to see in a simple table of numbers. b. A lean production tool to visually understand the flow of materials from supplier to customer that includes the current process and flow as well as the value-added and non-value-added time of all the process steps. Used to lead to reduction of waste, decrease flow time, and make the process flow more efficient and effective. c. Analytical methods to determine the core problem(s) of an organization, process, product, market, and so forth. The five whys is an example of this. d. In traditional management, performance measurements related to machine, worker, or department efficiency or utilization. These performance measurements are usually poorly correlated with organizational performance. e. The Japanese term for improvement; refers to continuing improvement involving everyone-managers and workers. In manufacturing, [this] relates to finding and eliminating waste in machinery, labor, or production methods Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started