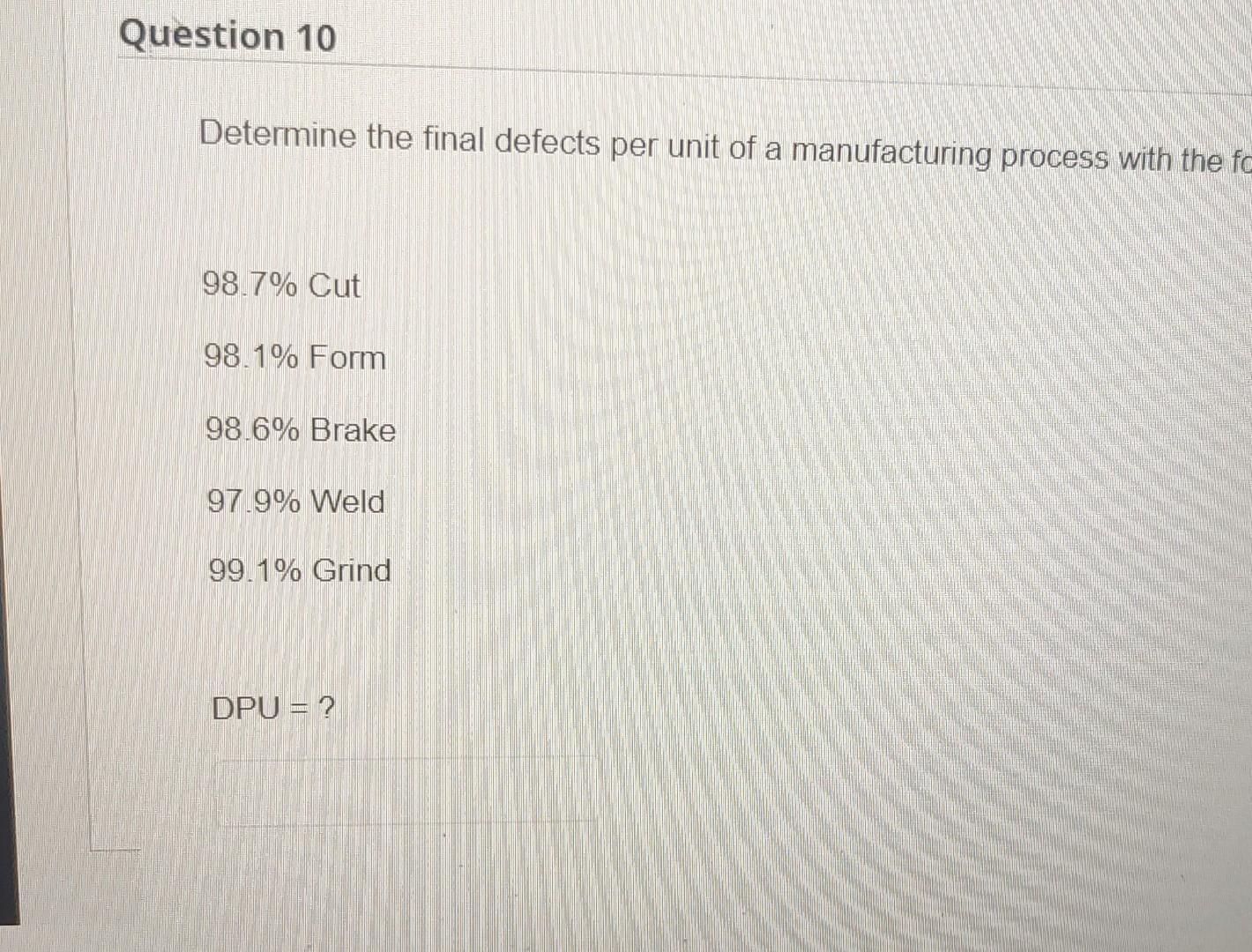

Question: Question 10 Determine the final defects per unit of a manufacturing process with the fc a 98.7% Cut 98.1% Form 98.6% Brake 97.9% Weld 99.1%

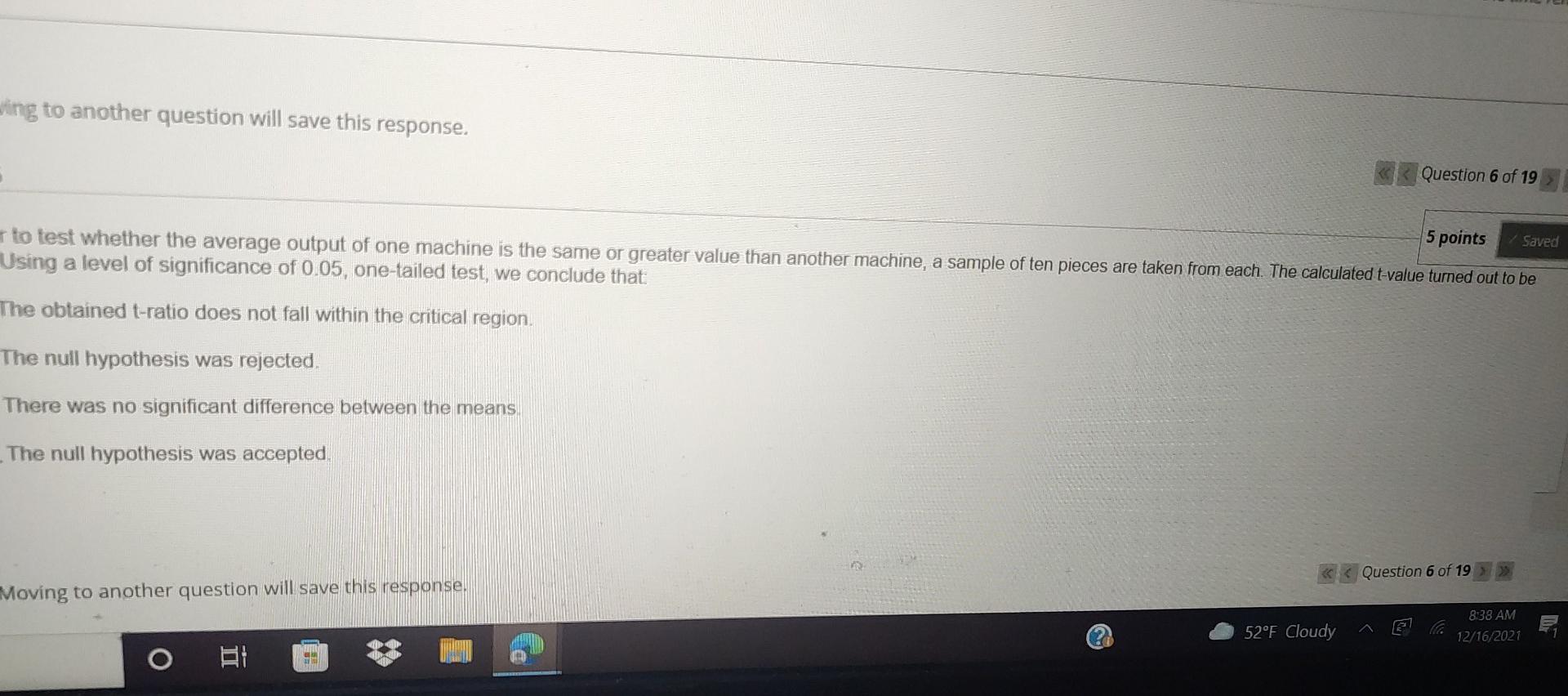

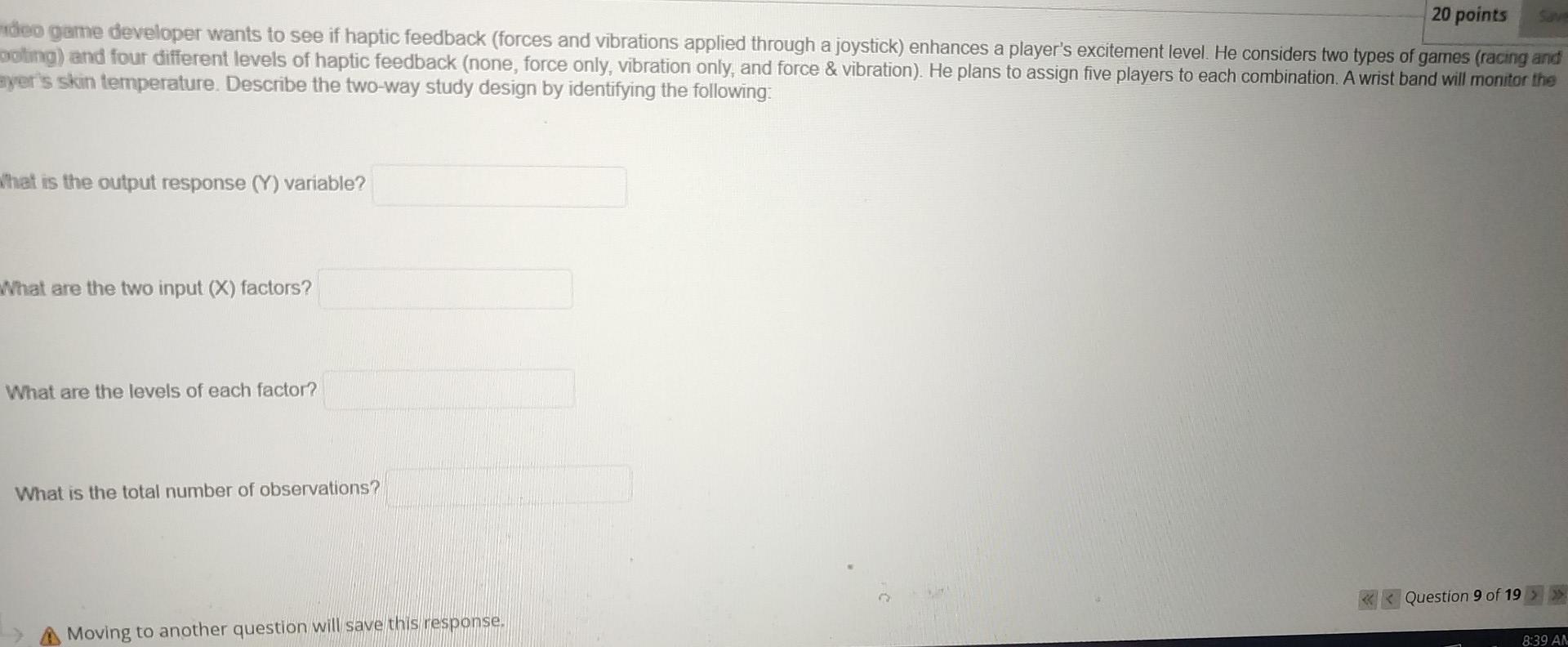

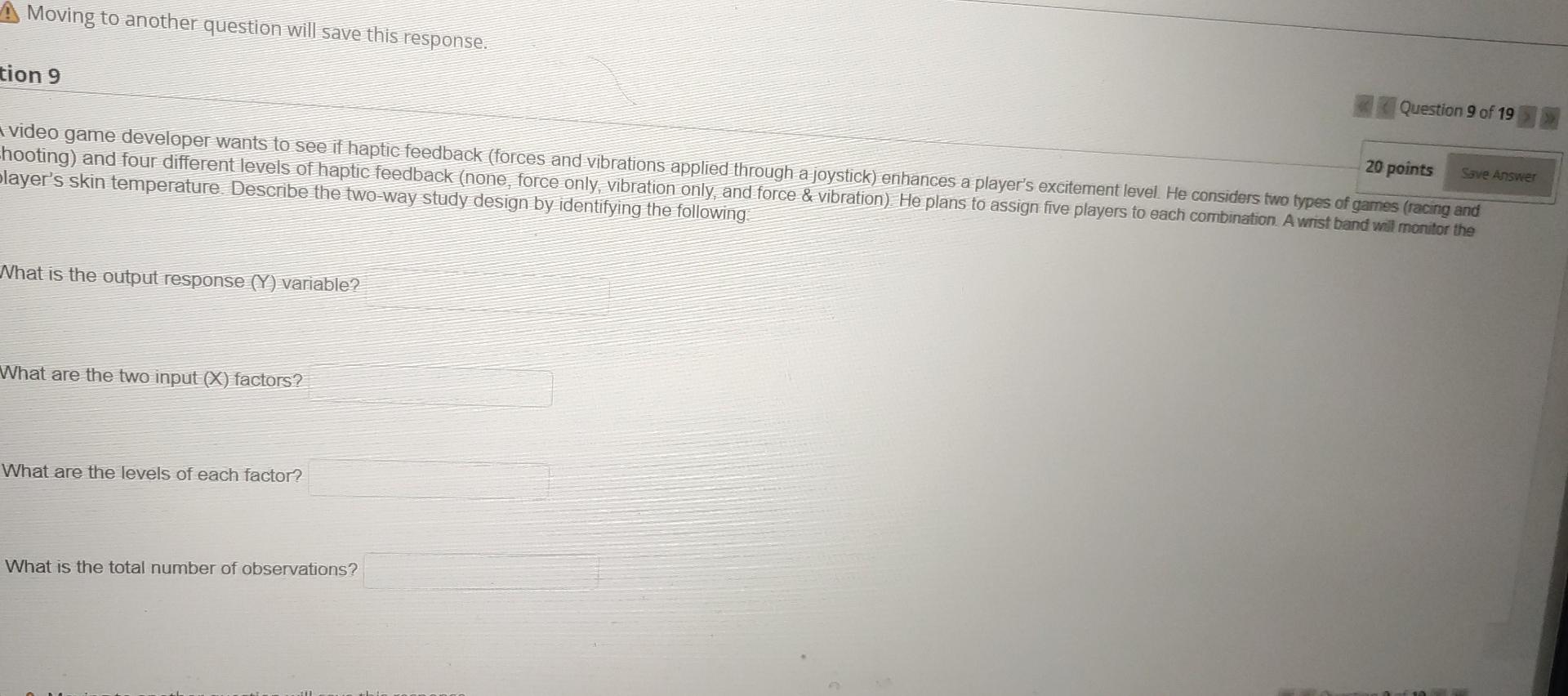

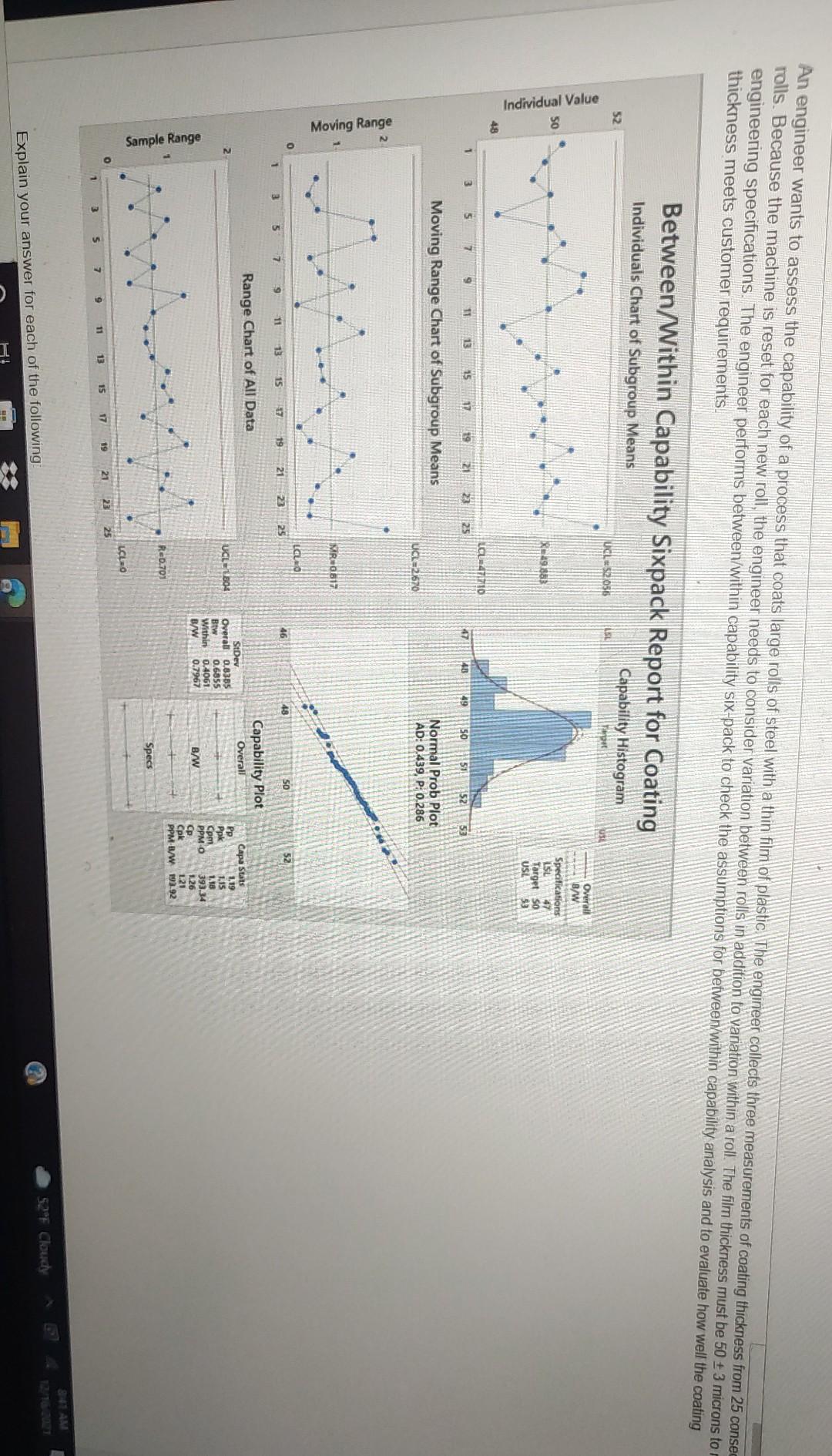

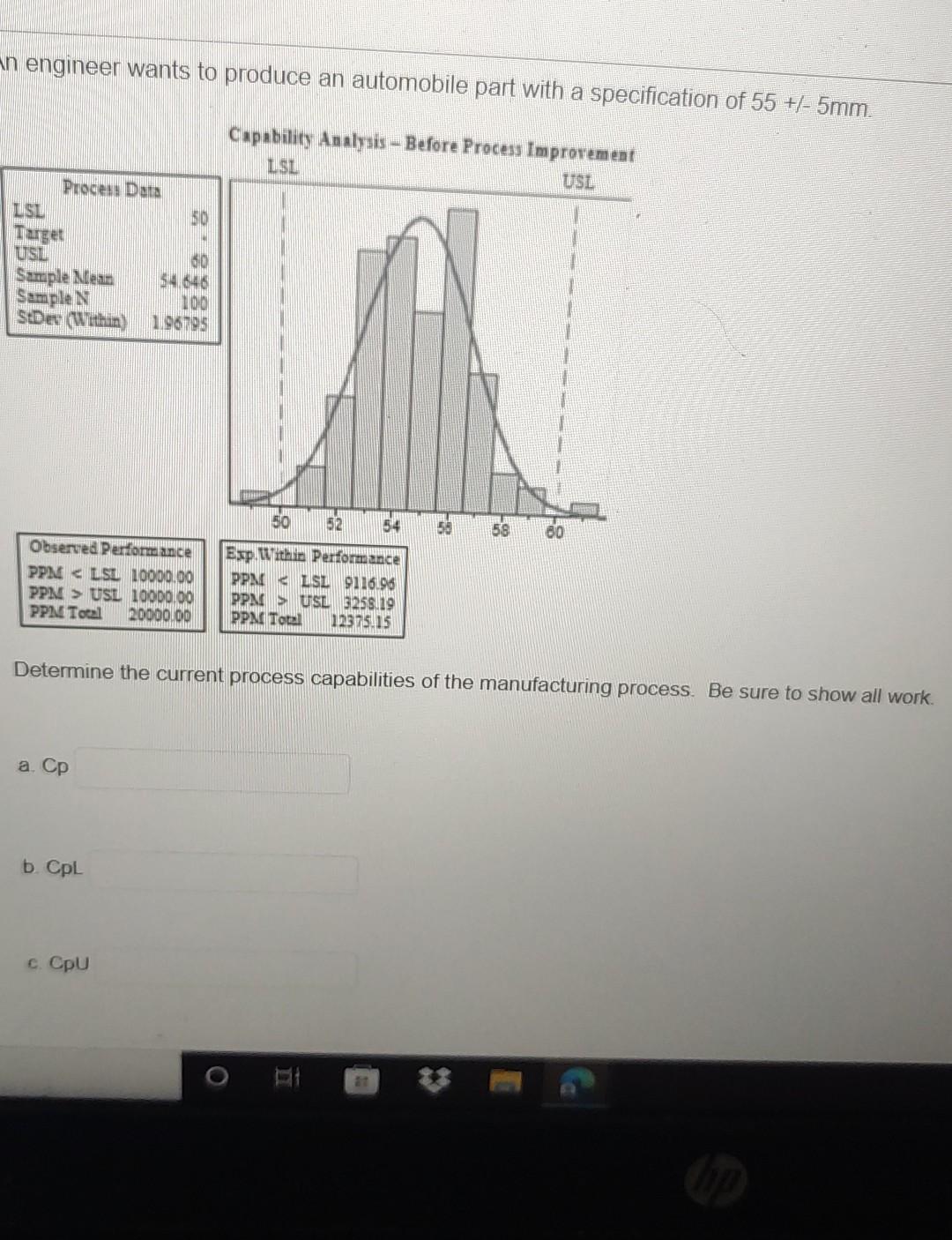

Question 10 Determine the final defects per unit of a manufacturing process with the fc a 98.7% Cut 98.1% Form 98.6% Brake 97.9% Weld 99.1% Grind DPU = ? ving to another question will save this response. Question 6 of 19 Saved 5 points to test whether the average output of one machine is the same or greater value than another machine, a sample of ten pieces are taken from each. The calculated t-value turned out to be Using a level of significance of 0.05, one-tailed test, we conclude that The obtained t-ratio does not fall within the critical region The null hypothesis was rejected There was no significant difference between the means The null hypothesis was accepted. Question 6 of 19 >> Moving to another question will save this response. 52F Cloudy 8:38 AM 12/16/2021 O 20 points adeo game developer wants to see if haptic feedback (forces and vibrations applied through a joystick) enhances a player's excitement level. He considers two types of games (racing and ooling) and four different levels of haptic feedback (none, force only, vibration only, and force & vibration). He plans to assign five players to each combination. A wrist band will monitor the ayer's skin temperature. Describe the two-way study design by identifying the following. what is the output response (V) variable? What are the two input (X) factors? What are the levels of each factor? What is the total number of observations? Question 9 of 19 > >> A Moving to another question will save this response. 8:39 AM A Moving to another question will save this response. Question 9 of 19 tion 9 20 points video game developer wants to see if haptic feedback (forces and vibrations applied through a joystick) enhances a player's excitement level He considers two types of games (racing and hooting) and four different levels of haptic feedback (none, force only, vibration only, and force & vibration) He plans to assign five players to each combination A wrist band will monitor the player's skin temperature. Describe the two-way study design by identifying the following: Save Answer Nhat is the output response (Y) variable? What are the two input (X) factors? What are the levels of each factor? What is the total number of observations? An engineer wants to assess the capability of a process that coats large rolls of steel with a thin film of plastic The engineer collects three measurements of coating thickness from 25 consec rolls. Because the machine is reset for each new roll, the engineer needs to consider variation between rolls in addition to variation within a roll. The film thickness must be 50 - 3 microns to engineering specifications. The engineer performs between/within capability six-pack to check the assumptions for between/within capability analysis and to evaluate how well the coating thickness meets customer requirements Between/Within Capability Sixpack Report for Coating Individuals Chart of Subgroup Means Capability Histogram 52 UCL 52056 (LSL UBI Individual Value SO Overall B/W Specifications LSL 47 Target $0 USL 53 49.883 LOL471710 1 3 5 2 9 11 13 15 17 19 21 23 25 47 48 49 15011151152153 Moving Range Chart of Subgroup Means Normal Prob Plot AD: 0.439, P: 0.286 UCL=2670 MR0817 LOLO 46 SO 52 9 11 13 15 7 Range Chart of All Data Capability Plot Overall UCL 1804 StDev Overall 0.8385 Btw 0.6855 Within 0.4061 B/W 0.7967 Capa Stats Pp 1,19 Ppk 1.IS Com 1.18 PPM O 393 34 Cp 126 Cpk 121 PPM B/W 193.92 B/W Sample Range Re0.701 Specs LCLEO 17 15 23 25 21 5 13 3 11 7 9 52F Clouch Explain your answer for each of the following In engineer wants to produce an automobile part with a specification of 55 +/- 5mm. Capability Analysis - Before Process Improvement LSL USL Process Data LSL 50 Tuget USLE 30 Sample Nean 54646 Sample N 100 SeDev Within 198795 50 132 4 50 58 80 Observed Performance PPM USL 10000.00 PPM Total 20000.00 Exp Within Performance PPM LSL 9116.96 PPN > USL 3258.19 PPM Total 12375.15 Determine the current process capabilities of the manufacturing process. Be sure to show all work. . b. CpL c. Cpu 27

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock