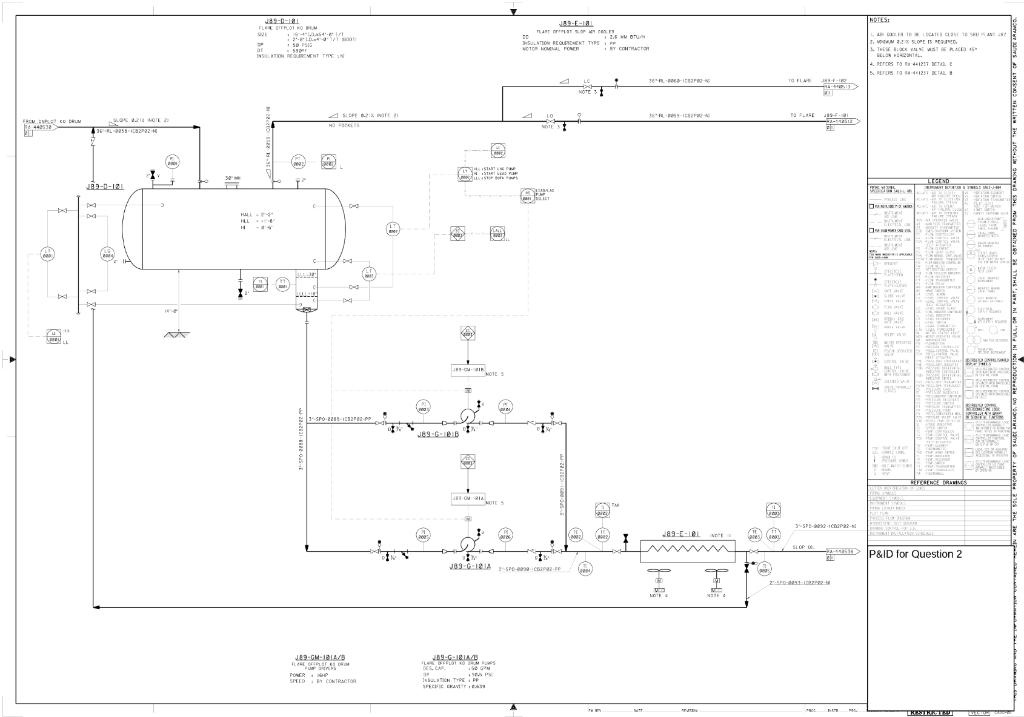

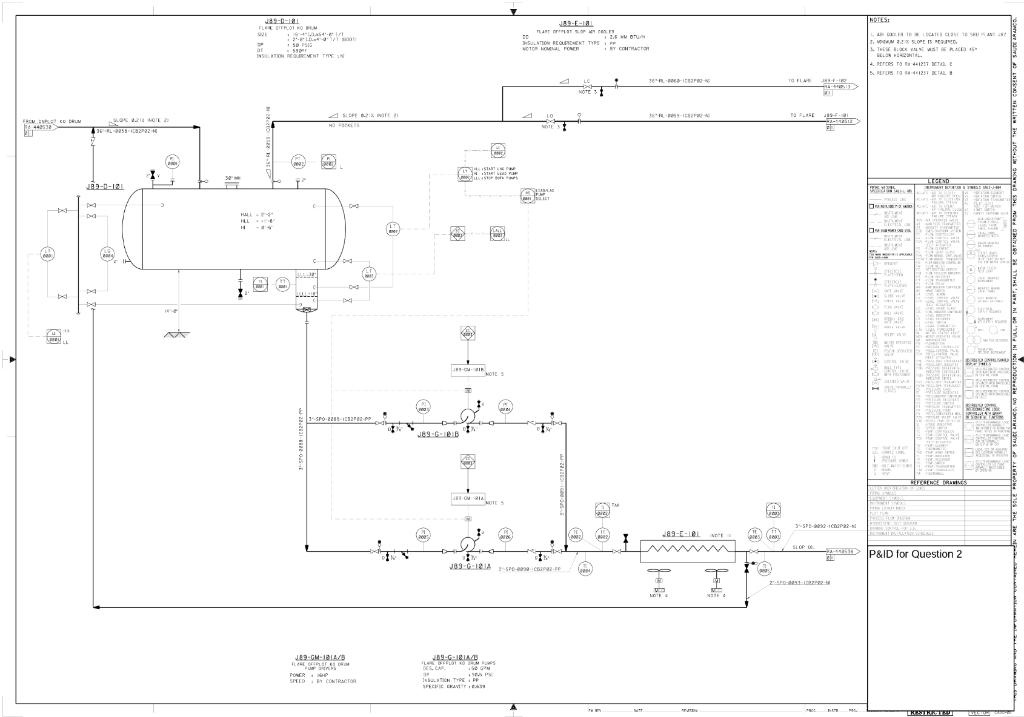

Question 2 (25\%): Attached is a Process and Instrumentation Diagram (P\&ID) of a Diesel Hydrotreater flaring system. The P\&ID shows Flare Knockout drum and air cooler. The pressurized feed comes to the knockout drum from different sources. The knockout drum separates the liquid and gaseous components. The gaseous component goes to flaring and the liquid part is air-cooled and sent to another processing unit. The knockout drum and cooling system is an essential safety system required during regular flaring and also emergency flaring and therefore this system requires a SIL 3. a) Review the existing safety system design of the diesel Hydrotreater flaring. Using tables, identify the existing "prevention" layers for knockout drum and air cooler (one table for knockout drum and one table for the air cooler). In your tables, indicate if a specific prevention layer is missing from the existing design. Hint: Follow the union model concept when evaluating the existing layers of prevention. b) A layer of protection analysis (LOPA) indicated that the existing safety system does not meet the requirements of SIL3. What "prevention" layer can be added to the current design to achieve SIL3? What key components/devices are required for your proposed additional prevention layer? Note: This question does not need any calculations. Refer to the LEGEND section of the drawing for the description of each symbol on the drawing. Question 2 (25\%): Attached is a Process and Instrumentation Diagram (P\&ID) of a Diesel Hydrotreater flaring system. The P\&ID shows Flare Knockout drum and air cooler. The pressurized feed comes to the knockout drum from different sources. The knockout drum separates the liquid and gaseous components. The gaseous component goes to flaring and the liquid part is air-cooled and sent to another processing unit. The knockout drum and cooling system is an essential safety system required during regular flaring and also emergency flaring and therefore this system requires a SIL 3. a) Review the existing safety system design of the diesel Hydrotreater flaring. Using tables, identify the existing "prevention" layers for knockout drum and air cooler (one table for knockout drum and one table for the air cooler). In your tables, indicate if a specific prevention layer is missing from the existing design. Hint: Follow the union model concept when evaluating the existing layers of prevention. b) A layer of protection analysis (LOPA) indicated that the existing safety system does not meet the requirements of SIL3. What "prevention" layer can be added to the current design to achieve SIL3? What key components/devices are required for your proposed additional prevention layer? Note: This question does not need any calculations. Refer to the LEGEND section of the drawing for the description of each symbol on the drawing