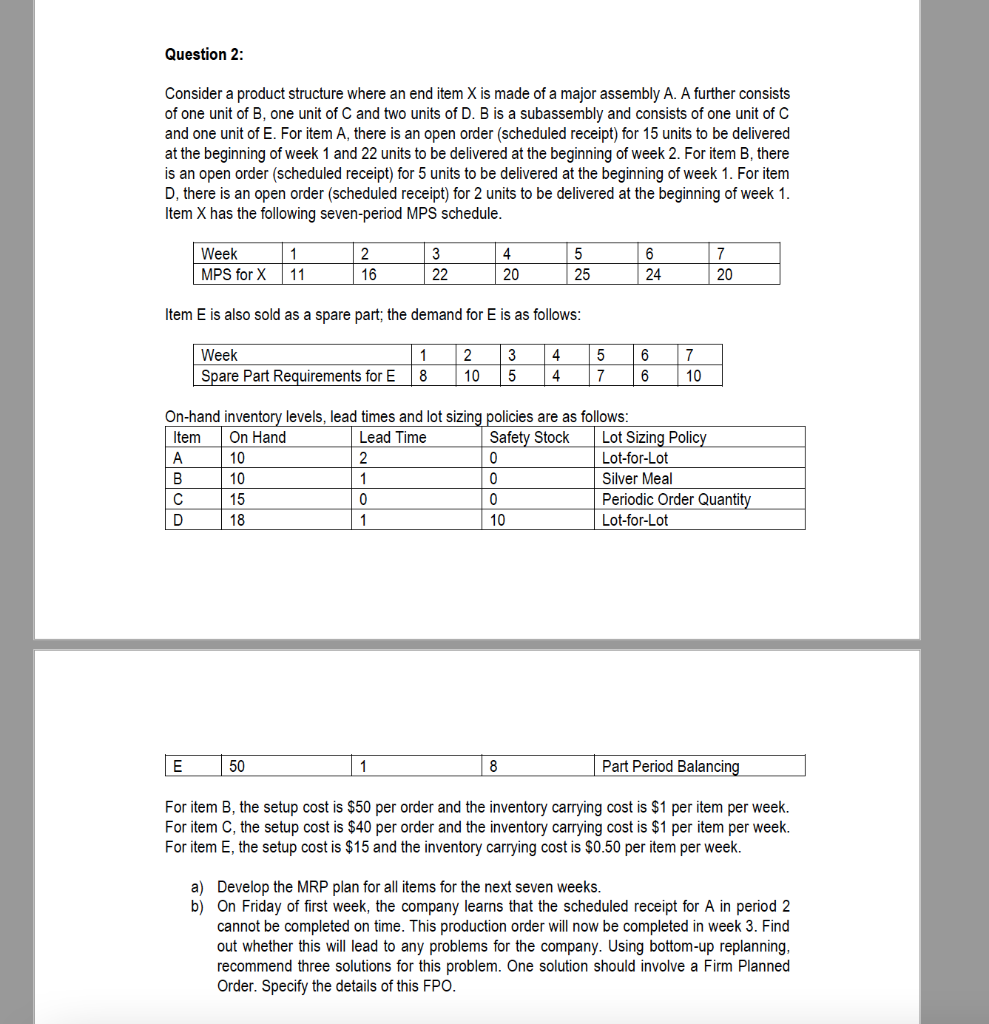

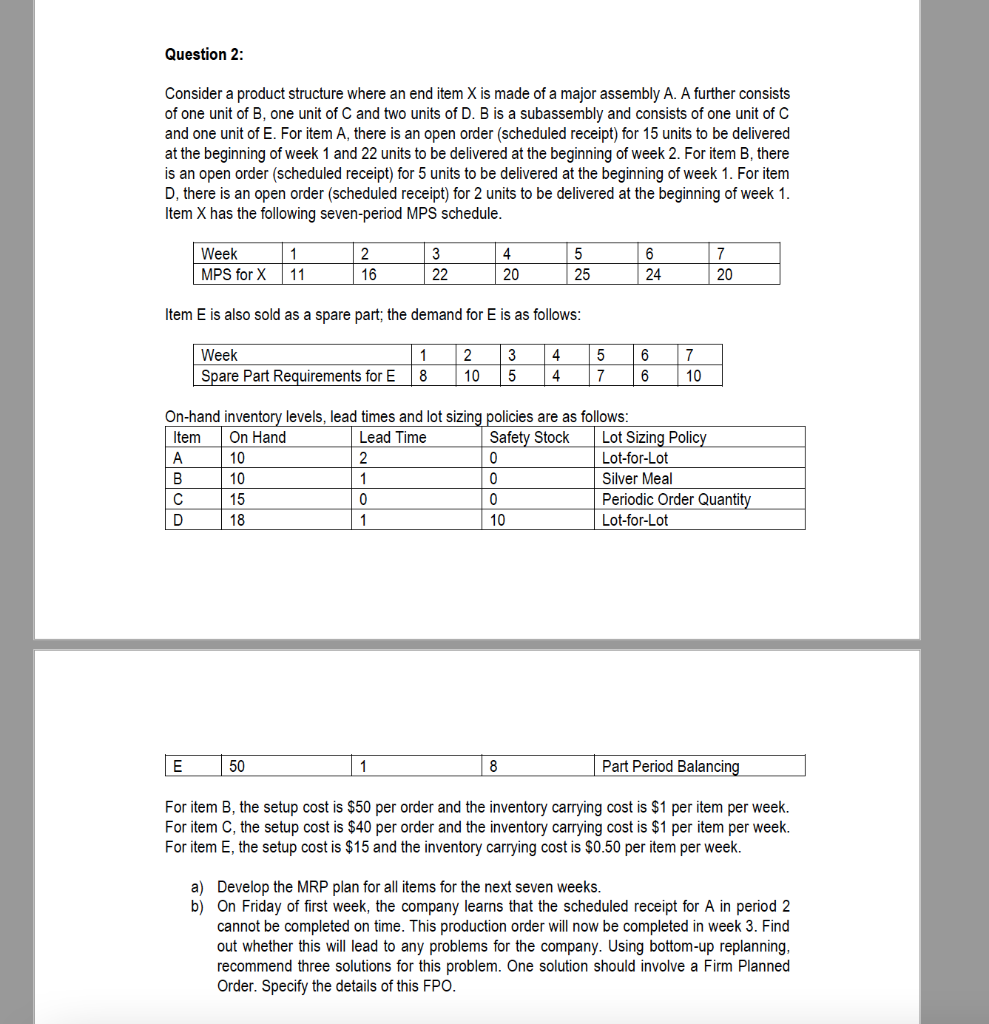

Question 2: Consider a product structure where an end item X is made of a major assembly A. A further consists of one unit of B, one unit of C and two units of D. B is a subassembly and consists of one unit of C and one unit of E. For item A, there is an open order (scheduled receipt) for 15 units to be delivered at the beginning of week 1 and 22 units to be delivered at the beginning of week 2. For item B, there is an open order (scheduled receipt) for 5 units to be delivered at the beginning of week 1. For item D, there is an open order (scheduled receipt) for 2 units to be delivered at the beginning of week 1. Item X has the following seven-period MPS schedule. 6 Week MPS for X 1 11 2 16 3 22 4 20 5 25 7 20 24 Item E is also sold as a spare part; the demand for E is as follows: Week Spare Part Requirements for E 1 8 2 10 3 5 4 4 5 7 6 6 7 10 On-hand inventory levels, lead times and lot sizing policies are as follows: Item On Hand Lead Time Safety Stock Lot Sizing Policy A 10 2 0 Lot-for-Lot B 10 1 0 Silver Meal 15 0 0 Periodic Order Quantity D 18 1 10 Lot-for-Lot E 50 1 8 Part Period Balancing For item B, the setup cost is $50 per order and the inventory carrying cost is $1 per item per week. For item C, the setup cost is $40 per order and the inventory carrying cost is $1 per item per week. For item E, the setup cost is $15 and the inventory carrying cost is $0.50 per item per week. a) Develop the MRP plan for all items for the next seven weeks. b) On Friday of first week, the company learns that the scheduled receipt for A in period 2 cannot be completed on time. This production order will now be completed in week 3. Find out whether this will lead to any problems for the company. Using bottom-up replanning, recommend three solutions for this problem. One solution should involve a Firm Planned Order. Specify the details of this FPO. Question 2: Consider a product structure where an end item X is made of a major assembly A. A further consists of one unit of B, one unit of C and two units of D. B is a subassembly and consists of one unit of C and one unit of E. For item A, there is an open order (scheduled receipt) for 15 units to be delivered at the beginning of week 1 and 22 units to be delivered at the beginning of week 2. For item B, there is an open order (scheduled receipt) for 5 units to be delivered at the beginning of week 1. For item D, there is an open order (scheduled receipt) for 2 units to be delivered at the beginning of week 1. Item X has the following seven-period MPS schedule. 6 Week MPS for X 1 11 2 16 3 22 4 20 5 25 7 20 24 Item E is also sold as a spare part; the demand for E is as follows: Week Spare Part Requirements for E 1 8 2 10 3 5 4 4 5 7 6 6 7 10 On-hand inventory levels, lead times and lot sizing policies are as follows: Item On Hand Lead Time Safety Stock Lot Sizing Policy A 10 2 0 Lot-for-Lot B 10 1 0 Silver Meal 15 0 0 Periodic Order Quantity D 18 1 10 Lot-for-Lot E 50 1 8 Part Period Balancing For item B, the setup cost is $50 per order and the inventory carrying cost is $1 per item per week. For item C, the setup cost is $40 per order and the inventory carrying cost is $1 per item per week. For item E, the setup cost is $15 and the inventory carrying cost is $0.50 per item per week. a) Develop the MRP plan for all items for the next seven weeks. b) On Friday of first week, the company learns that the scheduled receipt for A in period 2 cannot be completed on time. This production order will now be completed in week 3. Find out whether this will lead to any problems for the company. Using bottom-up replanning, recommend three solutions for this problem. One solution should involve a Firm Planned Order. Specify the details of this FPO