Answered step by step

Verified Expert Solution

Question

1 Approved Answer

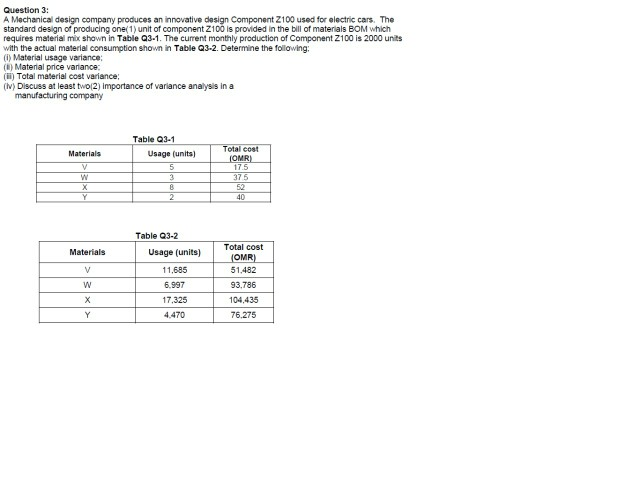

Question 3: A Mechanical design company produces an innovative design Component 2100 used for electric cars. The standard design of producing one(1) unit of component

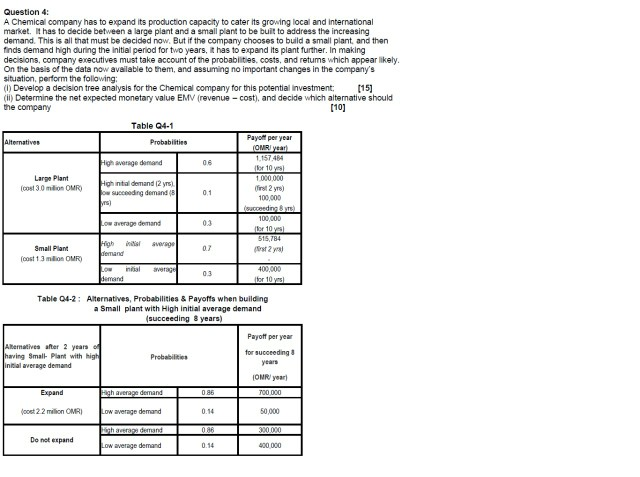

Question 3: A Mechanical design company produces an innovative design Component 2100 used for electric cars. The standard design of producing one(1) unit of component Z100 is provided in the bill of materials BOM which requires material mix shown in Table 93-1. The current monthly production of Component Z100 is 2000 units with the actual material consumption shown in Table Q3-2. Determine the following: (i) Material usage variance () Material price variance (1) Total material cost variance (1) Discuss at least two(2) Importance of variance analysis in a manufacturing company Materials V W X Y Table Q3-1 Usage (units) 5 3 B 2. Total cost (OMR) 17.5 375 52 40 Materials V Table Q3-2 Usage (units) 11,685 6.997 17.325 4.470 w Total cost (OMR) 51,482 93.786 104,435 76.275 X Y [15] Question 4: A Chemical company has to expand its production capacity to cater its growing local and international market. It has to decide between a large plant and a small plant to be buit to address the increasing demand. This is all that must be decided now. But if the company chooses to build a small plant and then finds demand high during the initial period for two years. It has to expand its plant further. In making decisions, company executives must take account of the probabilities, costs, and retums which appear likely On the basis of the data now available to them, and assuming no important changes in the company's situation, perform the following: (1) Develop a decision tree analysis for the Chemical company for this potential investment; (ii) Determine the net expected monetary value EMV (revenue -cost), and decide which alternative should the company (10) Table 24-1 Alternatives Probabilities Payoff per year 1.157,484 High average demand for 10 yel Large Plant 1.000.000 cost 3.0 milion OMR) High initial demand 2 yrs) 01 ou succeeding demand first 2 yrs) 100,000 succording 100.000 Low average demand 0.3 for 10 yes 515,784 High sve Small Plant 07 first 2 ya! (cost 13 million OMR) Low inal 400,000 03 Serrand Table 04-2: Alternatives, Probabilities & Payoffs when building a Small plant with High initial average demand (succeeding 8 years) Payoff per year Alternatives after 2 years for succeeding having Small Plant with high Probabilities initial average demand years IOMR/year Expand High average demand 0.85 700 000 (oost 2.2 million OMRI Low average demand 0.14 50,000 Laverapa demand 0.86 300.000 De not expand Low average demand 0.14 400 000

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started