Question: QUESTION: Define critical success factors (CSFs) and key performance indicators (KPIs) and explain how managers use them to measure the success of IS projects. CUSTOM

QUESTION: Define critical success factors (CSFs) and key performance indicators (KPIs) and explain how managers use them to measure the success of IS projects.

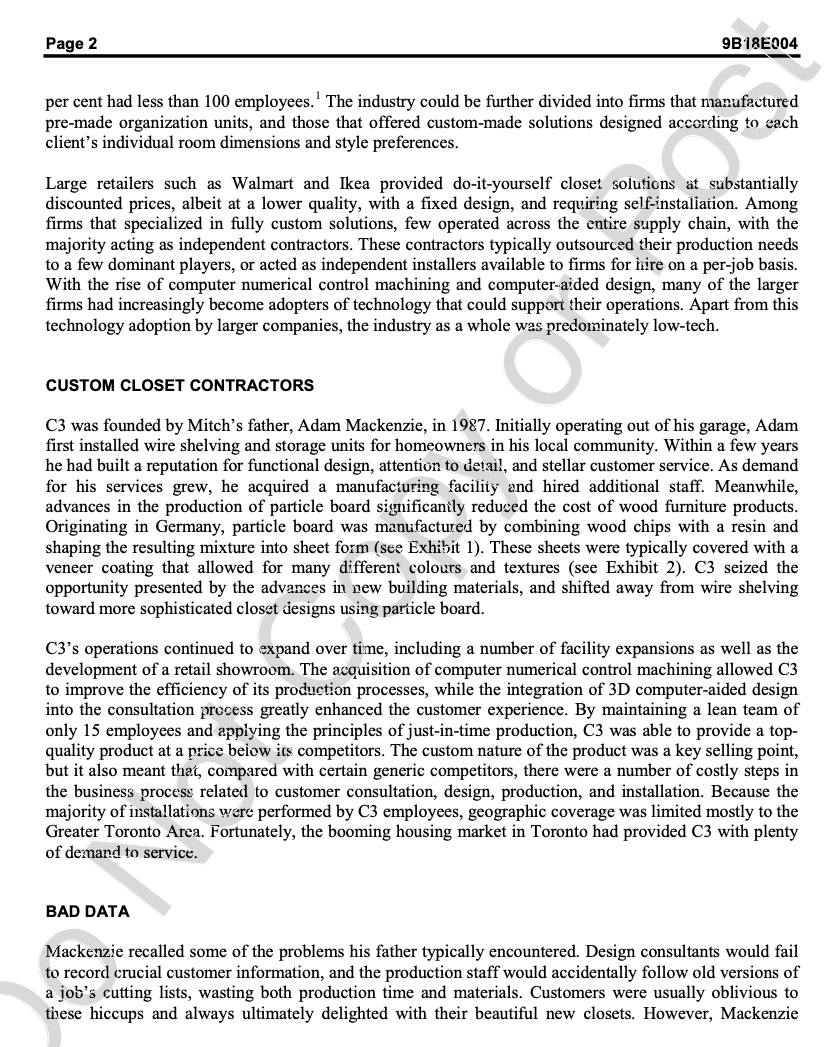

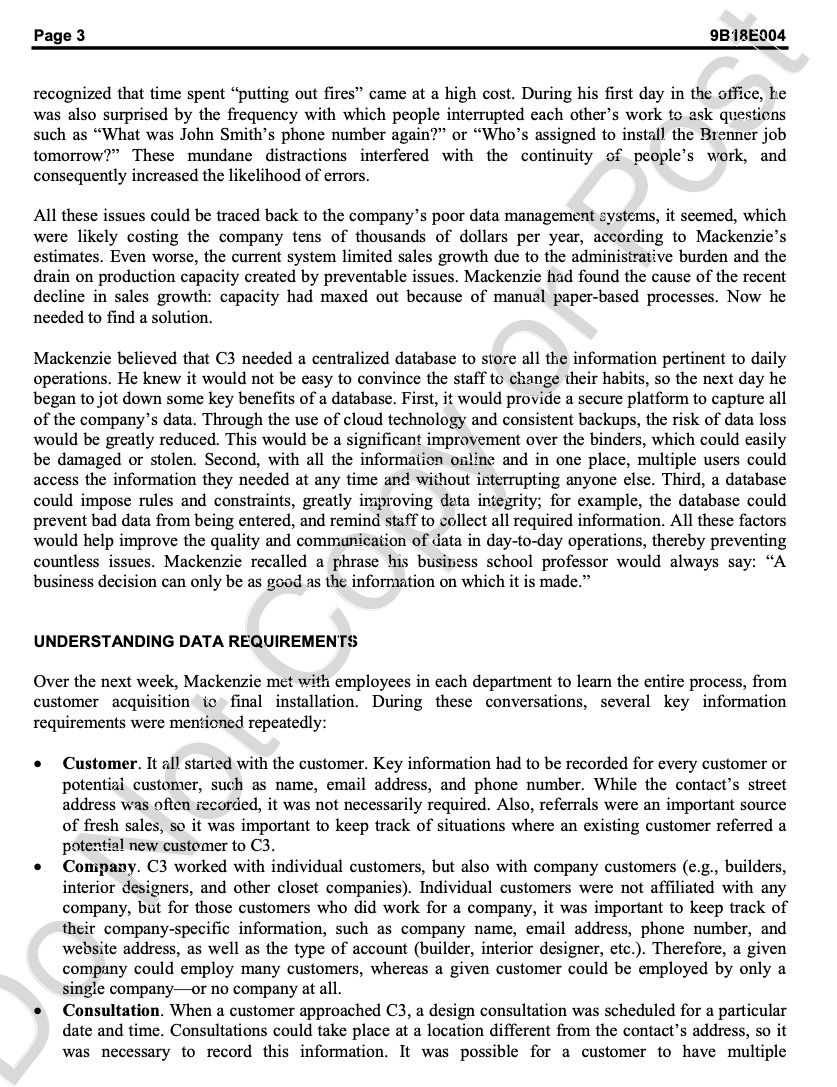

CUSTOM CLOSET CONTRACTORS: MAKING THE DATABASE CUT Michael Schwartz and Michael Gencarelli wrote this case under the supervision of Professor Derrick Neufeld solely to provide material for class discussion. The authors do not intend to illustrate either effective or ineffective handling of a managerial situation. The authors may have disguised certain names and other identifying information to protect confidentiality. This publication may not be transmitted, photocopied, digitized, or otherwise reproduced in any form or by any means without the permission of the copyright holder. Reproduction of this material is not covered under authorization by any reproduction rights organization. To order copies or request permission to reproduce materials, contact Ivey Publishing, Ivey Business School, Westem University, London, Ontario, Canada, NOG ON1; (t) 519.661.3208; (e) cases@ivey.ca; www.iveycases.com. Copyright 2018, Ivey Business School Foundation Version: 2018-03-06 As Mitch Mackenzie sipped his morning coffee on the way to work, he envisioned the value he hoped to bring to his family business, Custom Closet Contractors (C3), which designed, manufactured, and installed custom home organization solutions for home builders and individual clients. Mackenzie had just completed his third year of business school. He was eager to utilize his newly developed business and technology skill sets during his four-month summer position, and his father had just approved his proposal to conduct a comprehensive analysis of the company's operations in order to strengthen profitability. Mackenzie knew there were two basic paths to profitability: increasing revenues and lowering expenses. In the past year, the successful company's sales growth had slowed, while expenses as a percentage of sales had increased. Determined to understand why, Mackenzie met with Kathy Stauffer, the office administrator at C3, to gather information. Kathy, where can I find information on jobs currently in progress?" Mackenzie asked. I have them right here, Stauffer replied, pointing to a blue 5-inch ring binder on her desk. A chill crawled down Mackenzie's spine as a realization began to set in and a storm of questions flooded his head. "Is all our customer data paper-based? he asked, horrified. "Pretty much; everything aside from the accounting and 3D designs, Stauffer replied cheerfully. Mackenzie began to skim through the binder. Phone numbers and addresses were scribbled haphazardly across pages of closet designs, with invoices stapled to the back. All the miscommunication between the front office and the production staff his father had complained about over the years was starting to make sense. It seemed inconceivable that a successful company like C3 did not use an electronic database. Mackenzie slumped down in his chair; clearly, he would need to start from square one and map out all of the company's essential processes, from customer acquisition to final installation. With a final sip of his second cup of coffee, he hopped out of his chair and got to work. THE HOME ORGANIZATION INDUSTRY Home organization solutions included a wide variety of designs outside of traditional closets, such as home offices, laundry rooms, garage storage, and many others. In Canada, the home organization industry was one of many sub-sectors within the household and institutional furniture manufacturing industry. It was a highly fragmented market, with Statistics Canada reporting over 5,752 firms in 2016, of which 97.6 Page 2 9B18E004 per cent had less than 100 employees. The industry could be further divided into firms that manufactured pre-made organization units, and those that offered custom-made solutions designed according to each client's individual room dimensions and style preferences. Large retailers such as Walmart and Ikea provided do-it-yourself closet solutions at substantially discounted prices, albeit at a lower quality, with a fixed design, and requiring self-instaliation. Among firms that specialized in fully custom solutions, few operated across the entire supply chain, with the majority acting as independent contractors. These contractors typically outsourced their production needs to a few dominant players, or acted as independent installers available to firms for hire on a per-job basis. With the rise of computer numerical control machining and computer-aided design, many of the larger firms had increasingly become adopters of technology that could support their operations. Apart from this technology adoption by larger companies, the industry as a whole was predominately low-tech. CUSTOM CLOSET CONTRACTORS C3 was founded by Mitch's father, Adam Mackenzie, in 1987. Initially operating out of his garage, Adam first installed wire shelving and storage units for homeowners in his local community. Within a few years he had built a reputation for functional design, attention to detail, and stellar customer service. As demand for his services grew, he acquired a manufacturing facility and hired additional staff. Meanwhile, advances in the production of particle board significantly reduced the cost of wood furniture products. Originating in Germany, particle board was manufactured by combining wood chips with a resin and shaping the resulting mixture into sheet form (see Exhibit 1). These sheets were typically covered with a veneer coating that allowed for many different colours and textures (see Exhibit 2). C3 seized the opportunity presented by the advances in new building materials, and shifted away from wire shelving toward more sophisticated closet designs using particle board. C3's operations continued to expand over time, including a number of facility expansions as well as the development of a retail showroom. The acquisition of computer numerical control machining allowed C3 to improve the efficiency of its production processes, while the integration of 3D computer-aided design into the consultation process greatly enhanced the customer experience. By maintaining a lean team of only 15 employees and applying the principles of just-in-time production, C3 was able to provide a top- quality product at a price below its competitors. The custom nature of the product was a key selling point, but it also meant that, compared with certain generic competitors, there were a number of costly steps in the business process related to customer consultation, design, production, and installation. Because the majority of installations were performed by C3 employees, geographic coverage was limited mostly to the Greater Toronto Area. Fortunately, the booming housing market in Toronto had provided C3 with plenty of demand to service. BAD DATA Mackenzie recalled some of the problems his father typically encountered. Design consultants would fail to record crucial customer information, and the production staff would accidentally follow old versions of a job's cutting lists, wasting both production time and materials. Customers were usually oblivious to these hiccups and always ultimately delighted with their beautiful new closets. However, Mackenzie Page 3 9B18E004 recognized that time spent putting out fires" came at a high cost. During his first day in the office, he was also surprised by the frequency with which people interrupted each other's work to ask questions such as What was John Smith's phone number again? or Who's assigned to install the Brenner job tomorrow? These mundane distractions interfered with the continuity of people's work, and consequently increased the likelihood of errors. All these issues could be traced back to the company's poor data management systems, it seemed, which were likely costing the company tens of thousands of dollars per year, according to Mackenzie's estimates. Even worse, the current system limited sales growth due to the administrative burden and the drain on production capacity created by preventable issues. Mackenzie had found the cause of the recent decline in sales growth: capacity had maxed out because of manual paper-based processes. Now he needed to find a solution. . Mackenzie believed that C3 needed a centralized database to store all the information pertinent to daily operations. He knew it would not be easy to convince the staff to change their habits, so the next day he began to jot down some key benefits of a database. First, it would provide a secure platform to capture all of the company's data. Through the use of cloud technology and consistent backups, the risk of data loss would be greatly reduced. This would be a significant improvement over the binders, which could easily be damaged or stolen. Second, with all the information online and in one place, multiple users could access the information they needed at any time and without interrupting anyone else. Third, a database could impose rules and constraints, greatly improving data integrity; for example, the database could prevent bad data from being entered, and remind staff to collect all required information. All these factors would help improve the quality and communication of data in day-to-day operations, thereby preventing countless issues. Mackenzie recalled a phrase his business school professor would always say: "A business decision can only be as good as the information on which it is made." UNDERSTANDING DATA REQUIREMENTS Over the next week, Mackenzie met with employees in each department to learn the entire process, from customer acquisition to final installation. During these conversations, several key information requirements were mentioned repeatedly: . Customer. It all started with the customer. Key information had to be recorded for every customer or potential customer, such as name, email address, and phone number. While the contact's street address was often recorded, it was not necessarily required. Also, referrals were an important source of fresh sales, so it was important to keep track of situations where an existing customer referred a potential new customer to C3. Company. C3 worked with individual customers, but also with company customers (e.g., builders, interior designers, and other closet companies). Individual customers were not affiliated with any company, but for those customers who did work for a company, it was important to keep track of their company-specific information, such as company name, email address, phone number, and website address, as well as the type of account (builder, interior designer, etc.). Therefore, a given company could employ many customers, whereas a given customer could be employed by only a single companyor no company at all. Consultation. When a customer approached C3, a design consultation was scheduled for a particular date and time. Consultations could take place at a location different from the contact's address, so it was necessary to record this information. It was possible for a customer to have multiple Page 4 9B18E004 consultations, if needed, but each consultation involved only one customer. Furthermore, each consultation involved only one designer, but a designer was involved in many different consultations. Quote. After a successful consultation, a quote was generated and sent to the customer. A customer could have many quotes, but each quote was always specific to one customer. The quote contained lines that described each unit being purchased; for example, unit name (e.g., "Shoe Rack 73"), price ($189.99), quantity (1), and notes (e.g., desired colour, and installation location). A quote usually included multiple units (lines), and a given unit could appear on many different quotes. A quote also contained the total amount, the taxes, an optional discount rate for the customer, and an optional note. Additionally, it was important to track whether a quote was accepted or not. Installation. Once a quote was accepted, an installation was scheduled. Some jobs required multiple installations on different days, but each installation always related to one quote. In addition to the date and time of the installation, the address for the installation needed to be collected. This information could differ from the contact's address (e.g., when the contact was a builder). Only one installer was normally assigned to each installation, although multiple installers could be involved on larger jobs. Therefore, it was important to track which installers were responsible for each installation, including their names and contact information. Over time, the same installer could be involved on many different installations. DEVELOPING THE DATABASE By the end of the week, Mackenzie was beginning to understand how everything would fit together, and he was ready to start creating a data model. He first needed to list the key elements and relationships by breaking things down into their basic components, such as entities and attributes, and then linking them via identifiers and relationships. Finally, he had done some research into data modelling and decided that designing the model using Barker's notation' would be an ideal way to visualize the database. Eager to improve the company's data management systems, Mackenzie grabbed a pen and paper and began sketching out a preliminary data model. Page 4 9B18E004 consultations, if needed, but each consultation involved only one customer. Furthermore, each consultation involved only one designer, but a designer was involved in many different consultations. Quote. After a successful consultation, a quote was generated and sent to the customer. A customer could have many quotes, but each quote was always specific to one customer. The quote contained lines that described each unit being purchased; for example, unit name (e.g., "Shoe Rack 73"), price ($189.99), quantity (1), and notes (e.g., desired colour, and installation location). A quote usually included multiple units (lines), and a given unit could appear on many different quotes. A quote also contained the total amount, the taxes, an optional discount rate for the customer, and an optional note. Additionally, it was important to track whether a quote was accepted or not. Installation. Once a quote was accepted, an installation was scheduled. Some jobs required multiple installations on different days, but each installation always related to one quote. In addition to the date and time of the installation, the address for the installation needed to be collected. This information could differ from the contact's address (e.g., when the contact was a builder). Only one installer was normally assigned to each installation, although multiple installers could be involved on larger jobs. Therefore, it was important to track which installers were responsible for each installation, including their names and contact information. Over time, the same installer could be involved on many different installations. DEVELOPING THE DATABASE By the end of the week, Mackenzie was beginning to understand how everything would fit together, and he was ready to start creating a data model. He first needed to list the key elements and relationships by breaking things down into their basic components, such as entities and attributes, and then linking them via identifiers and relationships. Finally, he had done some research into data modelling and decided that designing the model using Barker's notation' would be an ideal way to visualize the database. Eager to improve the company's data management systems, Mackenzie grabbed a pen and paper and began sketching out a preliminary data model. Page 5 9B18E004 EXHIBIT 1: ORIENTED-STRAND BOARD AND PARTICLE BOARD or po Source: "Design Build Love: OSB and Particle Board," Flickr, Creative Commons License 2.0, January 24, 2012, accessed November 28, 2017, https://flic.kr/p/bi26G4. EXHIBIT 2: PARTICLE BOARD WITH VENEER COATING NO Source: "Particle Board with Veneer," Wikipedia, https://en.wikipedia.org/wiki/Particle_board#/media/File:Particleboard.jpg. accessed November 27 2017Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts