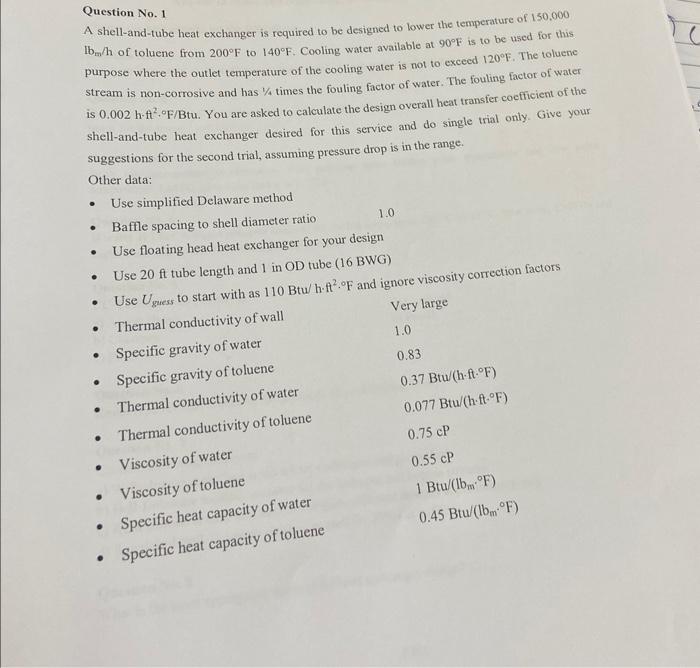

Question No. 1 A shell-and-tube heat exchanger is required to be designed to lower the temperature of 150.000 Ibm/h of toluene from 200F to 140F. Cooling water available at 90F is to be used for this purpose where the outlet temperature of the cooling water is not to exceed 120F. The toluene stream is non-corrosive and has 1/4 times the fouling factor of water. The fouling factor of water is 0.002hft2. F/Btu. You are asked to calculate the design overall heat transfer coefficient of the shell-and-tube heat exchanger desired for this service and do single trial only. Give your suggestions for the second trial, assuming pressure drop is in the range. Other data: - Use simplified Delaware method - Baffle spacing to shell diameter ratio 1.0 - Use floating head heat exchanger for your design - Use 20ft tube length and 1 in OD tube (16 BWG) - Use Uguess to start with as 110Btw/hft2FF and ignore viscosity correction factors - Thermal conductivity of wall - Specific gravity of water - Specific gravity of toluene - Thermal conductivity of water - Thermal conductivity of toluene - Viscosity of water - Viscosity of toluene - Specific heat capacity of water Very large 1.00.83 0.37Btw(hftF)0.077Btu/(hftF) 0.75cP 0.55cP - Specific heat capacity of toluene 1Btu/(1bm.F) 0.45Btu(1bmF) Question No. 1 A shell-and-tube heat exchanger is required to be designed to lower the temperature of 150.000 Ibm/h of toluene from 200F to 140F. Cooling water available at 90F is to be used for this purpose where the outlet temperature of the cooling water is not to exceed 120F. The toluene stream is non-corrosive and has 1/4 times the fouling factor of water. The fouling factor of water is 0.002hft2. F/Btu. You are asked to calculate the design overall heat transfer coefficient of the shell-and-tube heat exchanger desired for this service and do single trial only. Give your suggestions for the second trial, assuming pressure drop is in the range. Other data: - Use simplified Delaware method - Baffle spacing to shell diameter ratio 1.0 - Use floating head heat exchanger for your design - Use 20ft tube length and 1 in OD tube (16 BWG) - Use Uguess to start with as 110Btw/hft2FF and ignore viscosity correction factors - Thermal conductivity of wall - Specific gravity of water - Specific gravity of toluene - Thermal conductivity of water - Thermal conductivity of toluene - Viscosity of water - Viscosity of toluene - Specific heat capacity of water Very large 1.00.83 0.37Btw(hftF)0.077Btu/(hftF) 0.75cP 0.55cP - Specific heat capacity of toluene 1Btu/(1bm.F) 0.45Btu(1bmF)