Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Questions: Questions What are the key success factors in this industry at the time of the case? How has Carded Graphics positioned itself to excel?

Questions:

Questions

- What are the key success factors in this industry at the time of the case? How has Carded Graphics positioned itself to excel?

- What are the non-quantifiable and strategic benefits of replacing the machine?

- What are the relevant cash flows for the replacement decision? (Hint: for a replacement decision, analysts often find it helpful to prepare two sets of cash flows and two net present values (NPVs) one for the old machine and one for the new machine.)

- What are the initial outlays for each machine?

- What are the net cash flows associated with the old machine and the new machine?

- What are the terminal values of each machine (after-tax salvage value, if any, plus the recovery of NWC)?

- Using 8.5% discount rate and assuming 30% tax rate, what is the NPV for the replacement decision? Does the incremental NPV warrant the replacement of the old machine?

- Now assume 5% inflation rate (instead of 2% given in the case) and redo your calculations in part 3. Inflation will affect operating costs and labor costs. Inflation will also affect the discount rate by increasing it to 11.69%. Does this adjustment affect the attractiveness of the new machine?

- Please conduct sensitivity analysis and estimate the impact on incremental NPV of the replacement decision from a change in any of the following elements:

- Downstream waste of the new machine is 0.8%. What about 1.6%?

- The annual growth in necessary volume is 3%. What about 7%?

- Now go back to part 3 and assume that due to obsolescence the old machine will not last for eight years and needs to be replaced in two years. The new machine will still go for eight years if installed today. Estimate the total cash flows associated with the old machine (they should stay the same for the new machine), and calculate the Equivalent Annual Cash Flow for each. Is investing in the new machine a good idea based on these calculations?

- Please consider an alternative to replacement decision. The firm can simply purchase precut paper for the next 8 years instead of cutting it on its own. In other words, the firm can sell the old machine today, and purchase precut paper to satisfy its necessary volume of processed paper. The only costs that the firm will need to incur is the cost of precut paper and the downstream waste of using precut paper equal to 1.8% of the total cost of precut paper. Will this alternative solution be more attractive compared to the replacement?

- Based on the above analysis, what should be Carded Graphics decision regarding the replacement of old machine? Make sure to explain the primary reasons that justify your recommended course of action.

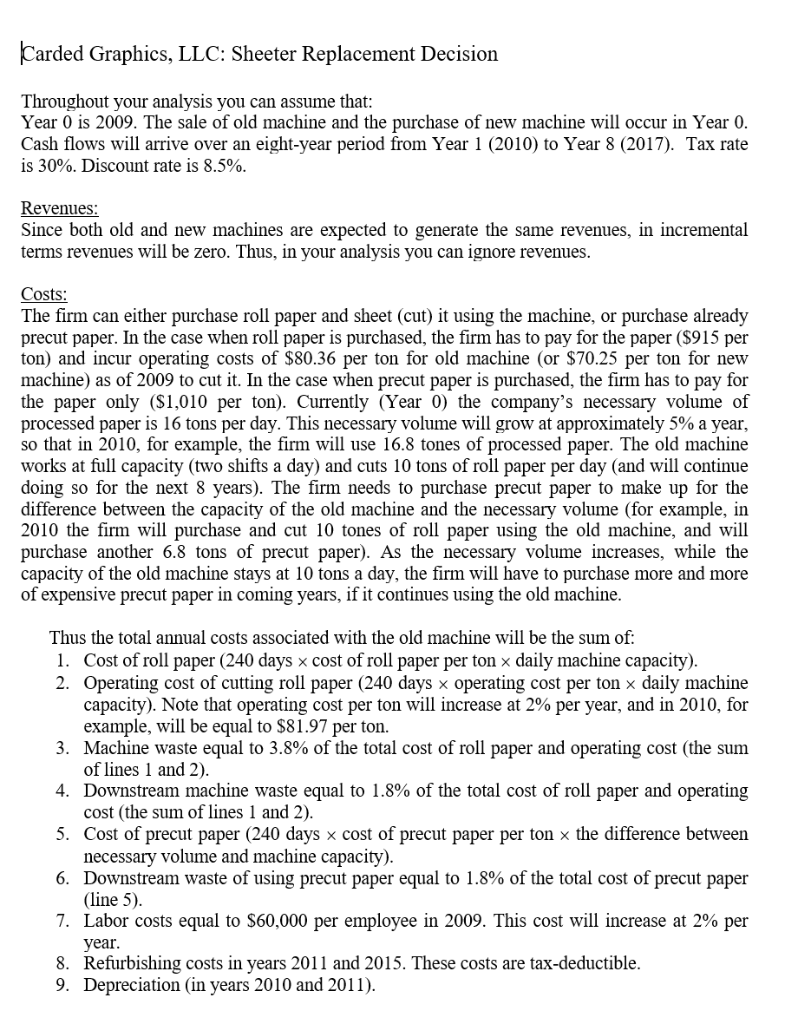

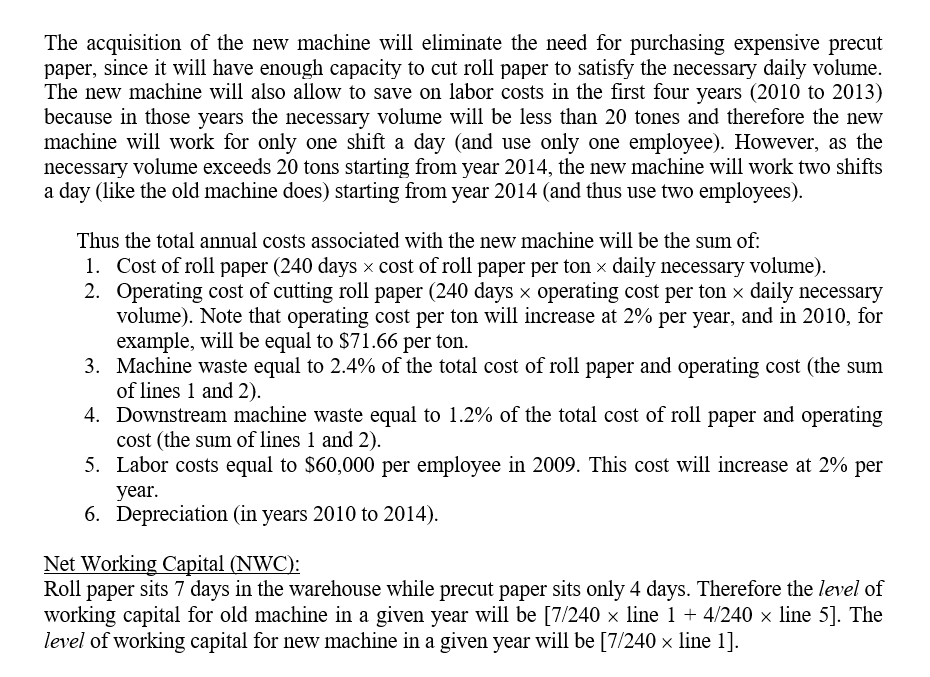

Carded Graphics, LLC: Sheeter Replacement Decision Throughout your analysis you can assume that Year 0 is 2009. The sale of old machine and the purchase of new machine will occur in Year 0 Cash flows will arrive over an eight-year period from Year 1 (2010) to Year 8 (2017). Tax rate is 30%. Discount rate is 8.5% Revenues Since both old and new machines are expected to generate the same revenues, in incremental terms revenues will be zero. Thus, in your analysis you can ignore revenues Costs: The firm can either purchase roll paper and sheet (cut) it using the machine, or purchase already precut paper. In the case when roll paper is purchased, the firm has to pay for the paper (S915 per ton) and incur operating costs of $80.36 per ton for old machine (or $70.25 per ton for new machine) as of 2009 to cut it. In the case when precut paper is purchased, the firm has to pay for the paper only ($1,010 per ton). Currently (Year 0) the company's necessary volume of processed paper is 16 tons per day. This necessary volume will grow at approximately 5% a year so that in 2010, for example, the firm will use 16.8 tones of processed paper. The old machine works at full capacity (two shifts a day) and cuts 10 tons of roll paper per day (and will continue doing so for the next 8 years). The firm needs to purchase precut paper to make up for the difference between the capacity of the old machine and the necessary volume (for example, in 2010 the firm will purchase and cut 10 tones of roll paper using the old machine, and will purchase another 6.8 tons of precut paper). As the necessary volume increases, while the capacity of the old machine stays at 10 tons a day, the firm will have to purchase more and more of expensive precut paper in coming years, if it continues using the old machine Thus the total annual costs associated with the old machine will be the sum of: 1. Cost of roll paper (240 days x cost of roll paper per ton x daily machine capacity) 2. Operating cost of cutting roll paper (240 days operating cost per ton daily machine capacity). Note that operating cost per ton will increase at 2% per year, and in 2010, for 3. Machine waste equal to 3.8% of the total cost of roll paper and operating cost (the sum 4. Downstream machine waste equal to 1.8% of the total cost of roll paper and operating 5. Cost of precut paper (240 days x cost of precut paper per ton x the difference between 6. Downstream waste of using precut paper equal to 1.8% of the total cost of precut paper 7, Labor costs equal to $60,000 per employee in 2009. This cost will increase at 2% per 8. Refurbishing costs in years 2011 and 2015. These costs are tax-deductible example, will be equal to $81.97 per ton. of lines 1 and 2) cost (the sum of lines 1 and 2) necessary volume and machine capacity) (line 5) year Depreciation (in years 2010 and 2011) 9. The acquisition of the new machine will eliminate the need for purchasing expensive precut paper, since it will have enough capacity to cut roll paper to satisfy the necessary daily volume. The new machine will also allow to save on labor costs in the first four years (2010 to 2013) because in those years the necessary volume will be less than 20 tones and therefore the nevw machine will work for only one shift a day (and use only one employee). However, as the necessary volume exceeds 20 tons starting from year 2014, the new machine will work two shifts a day (like the old machine does) starting from year 2014 (and thus use two employees) Thus the total annual costs associated with the new machine will be the sum of 1. Cost of roll paper (240 days x cost of roll paper per ton x daily necessary volume) 2. Operating cost of cutting roll paper (240 days x operating cost per ton x daily necessary volume). Note that operating cost per ton will increase at 2% per year, and in 2010, for 3. Machine waste equal to 2.4% of the total cost of roll paper and operating cost(the sum 4. Downstream machine waste equal to 1.2% of the total cost of roll paper and operating 5. Labor costs equal to $60,000 per employee in 2009. This cost will increase at 2% per example, will be equal to S71.66 per ton of lines 1 and 2) cost (the sum of lines 1 and 2) vear 6. Depreciation (in years 2010 to 2014) Net Working Capital (NWC Roll paper sits 7 days in the warehouse while precut paper sits only 4 days. Therefore the level of working capital for old machine in a given year will be [7/24 line l-4/240 x line 5]. The level of working capital for new machine in a given year will be [7/240 x line 1] Carded Graphics, LLC: Sheeter Replacement Decision Throughout your analysis you can assume that Year 0 is 2009. The sale of old machine and the purchase of new machine will occur in Year 0 Cash flows will arrive over an eight-year period from Year 1 (2010) to Year 8 (2017). Tax rate is 30%. Discount rate is 8.5% Revenues Since both old and new machines are expected to generate the same revenues, in incremental terms revenues will be zero. Thus, in your analysis you can ignore revenues Costs: The firm can either purchase roll paper and sheet (cut) it using the machine, or purchase already precut paper. In the case when roll paper is purchased, the firm has to pay for the paper (S915 per ton) and incur operating costs of $80.36 per ton for old machine (or $70.25 per ton for new machine) as of 2009 to cut it. In the case when precut paper is purchased, the firm has to pay for the paper only ($1,010 per ton). Currently (Year 0) the company's necessary volume of processed paper is 16 tons per day. This necessary volume will grow at approximately 5% a year so that in 2010, for example, the firm will use 16.8 tones of processed paper. The old machine works at full capacity (two shifts a day) and cuts 10 tons of roll paper per day (and will continue doing so for the next 8 years). The firm needs to purchase precut paper to make up for the difference between the capacity of the old machine and the necessary volume (for example, in 2010 the firm will purchase and cut 10 tones of roll paper using the old machine, and will purchase another 6.8 tons of precut paper). As the necessary volume increases, while the capacity of the old machine stays at 10 tons a day, the firm will have to purchase more and more of expensive precut paper in coming years, if it continues using the old machine Thus the total annual costs associated with the old machine will be the sum of: 1. Cost of roll paper (240 days x cost of roll paper per ton x daily machine capacity) 2. Operating cost of cutting roll paper (240 days operating cost per ton daily machine capacity). Note that operating cost per ton will increase at 2% per year, and in 2010, for 3. Machine waste equal to 3.8% of the total cost of roll paper and operating cost (the sum 4. Downstream machine waste equal to 1.8% of the total cost of roll paper and operating 5. Cost of precut paper (240 days x cost of precut paper per ton x the difference between 6. Downstream waste of using precut paper equal to 1.8% of the total cost of precut paper 7, Labor costs equal to $60,000 per employee in 2009. This cost will increase at 2% per 8. Refurbishing costs in years 2011 and 2015. These costs are tax-deductible example, will be equal to $81.97 per ton. of lines 1 and 2) cost (the sum of lines 1 and 2) necessary volume and machine capacity) (line 5) year Depreciation (in years 2010 and 2011) 9. The acquisition of the new machine will eliminate the need for purchasing expensive precut paper, since it will have enough capacity to cut roll paper to satisfy the necessary daily volume. The new machine will also allow to save on labor costs in the first four years (2010 to 2013) because in those years the necessary volume will be less than 20 tones and therefore the nevw machine will work for only one shift a day (and use only one employee). However, as the necessary volume exceeds 20 tons starting from year 2014, the new machine will work two shifts a day (like the old machine does) starting from year 2014 (and thus use two employees) Thus the total annual costs associated with the new machine will be the sum of 1. Cost of roll paper (240 days x cost of roll paper per ton x daily necessary volume) 2. Operating cost of cutting roll paper (240 days x operating cost per ton x daily necessary volume). Note that operating cost per ton will increase at 2% per year, and in 2010, for 3. Machine waste equal to 2.4% of the total cost of roll paper and operating cost(the sum 4. Downstream machine waste equal to 1.2% of the total cost of roll paper and operating 5. Labor costs equal to $60,000 per employee in 2009. This cost will increase at 2% per example, will be equal to S71.66 per ton of lines 1 and 2) cost (the sum of lines 1 and 2) vear 6. Depreciation (in years 2010 to 2014) Net Working Capital (NWC Roll paper sits 7 days in the warehouse while precut paper sits only 4 days. Therefore the level of working capital for old machine in a given year will be [7/24 line l-4/240 x line 5]. The level of working capital for new machine in a given year will be [7/240 x line 1]

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started