Question: Step through the examples shown on pages 1 through 3. Read over the information given on page 4, this will help you complete page 5

![Period 5. Beg. Inv. [220] - Forecast Demand [100] - 120 Period 6: Beg Inv. (120) - Forecast Demand [120] -0 P.A. Inventory-0](https://dsd5zvtm8ll6.cloudfront.net/si.experts.images/questions/2020/10/5f8418c018fbf_1602492587728.jpg)

Step through the examples shown on pages 1 through 3.

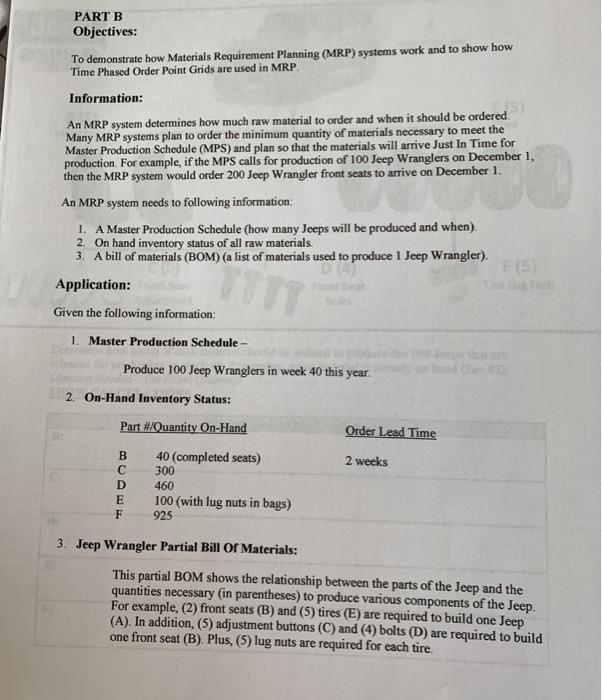

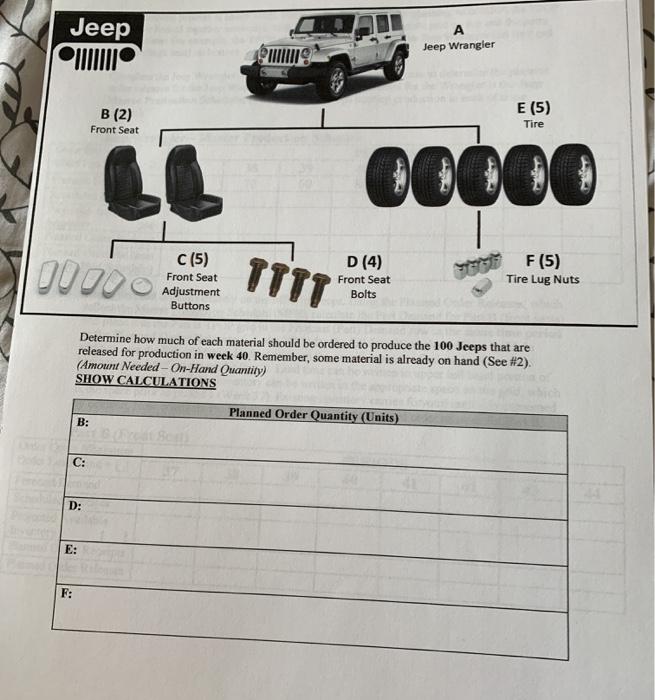

Read over the information given on page 4, this will help you complete page 5 where you need determine how much of each material should be ordered to produce the 100 Jeeps. Find out how much you need but subtract any existing inventory found at the part level (e.g., buttons) and sub-assembly level (e.g., buttons on assembled seats). You’re building 100 Jeeps. So, in the first box (B), you need to find out how many seats you need to meet production. Notice that on the previous page you have some items inventory. After adjusting for inventory, you should be able to determine the number of units left to order. Realize that the “completed seats” have bolts and buttons already attached. This would be counted as inventory because you wouldn’t need to order them. Same for the tires that are in stock that already have lugs. To get you started, there’s 40 seats in stock. Each Jeep has 2 front seats, so 100 x 2 = 200 subtract the 40 seats in stock will give you your planned order quantity.

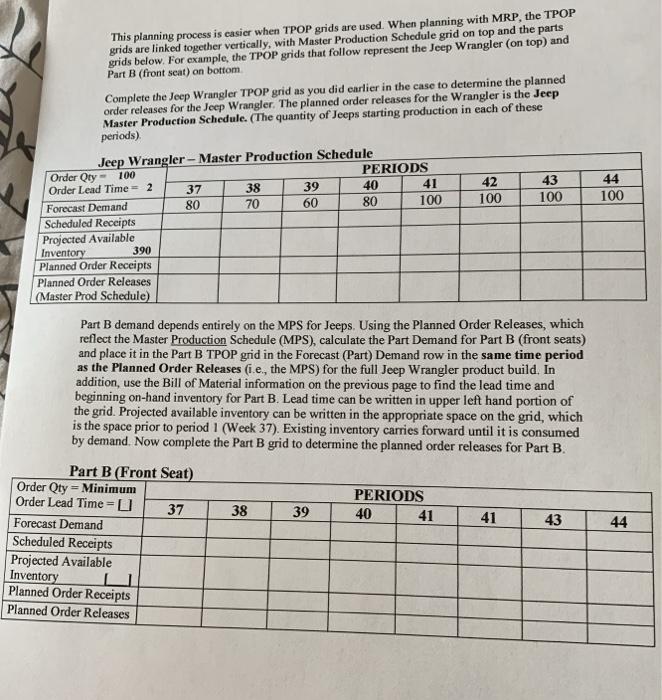

The examples from the previous pages will help you complete the two grids on page 6. When planning with MRP, the TPOP grids are linked together vertically, with Master Production Schedule grid on top and the parts grids below. For example, the TPOP grids on page 6 represent the Jeep Wrangler (on top) and Part B (front seat) on bottom. The top grid has a specified order quantity, while the bottom grid behaves in a Lean/Just in Time manner allowing you to order exactly what you need when you need it using a minimum order quantity. On page 6, you’re completing the top grid for finished Jeeps, working through the grid left to right. Anything in the release row, when it’s all said and done, will cascade down to the bottom grid. So, for example, you should have a Planned Order Release of 100 Jeeps in period 40, which means you now have demand for 200 seats in period 40 that you would enter in the bottom grid. You shouldn’t have any demand up to this point because you had plenty of finished jeeps in stock to this point. Check page 4, you will note that you have 40 seats in inventory. You should also note the lead time for seats. You need this information to complete the bottom grid. Your inventory will carry forward over a number of periods until you need it.

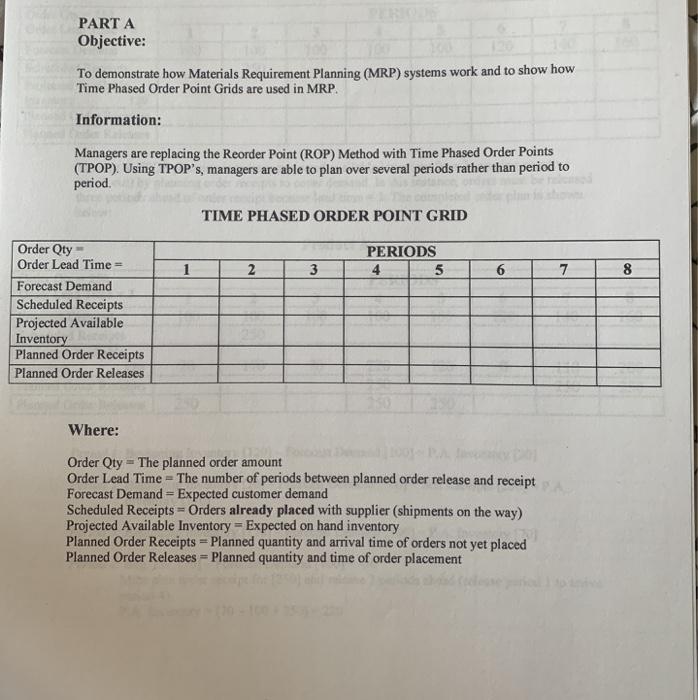

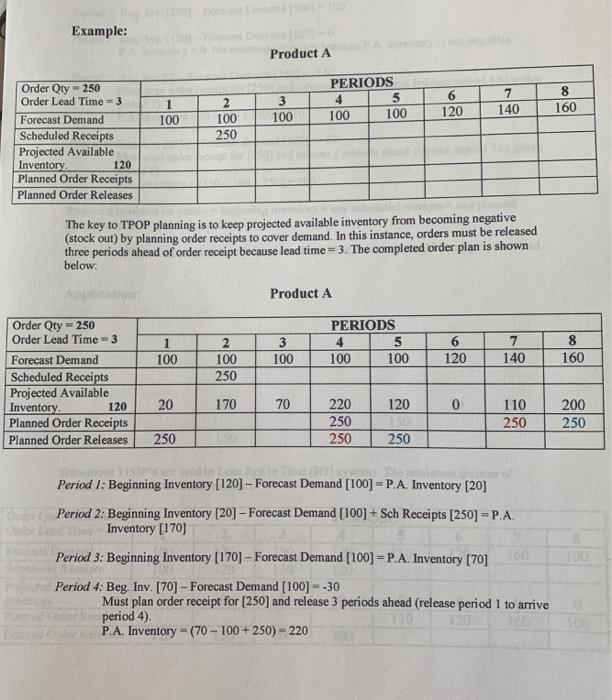

PART A Objective: To demonstrate how Materials Requirement Planning (MRP) systems work and to show how Time Phased Order Point Grids are used in MRP. Information: Managers are replacing the Reorder Point (ROP) Method with Time Phased Order Points (TPOP). Using TPOP's, managers are able to plan over several periods rather than period to period. Order Qty Order Lead Time= M Forecast Demand Scheduled Receipts Projected Available Inventory Planned Order Receipts Planned Order Releases 1 TIME PHASED ORDER POINT GRID PERIODS 4 2 3 5 6 Where: Order Qty - The planned order amount Order Lead Time The number of periods between planned order release and receipt Forecast Demand = Expected customer demand Scheduled Receipts=Orders already placed with supplier (shipments on the way) Projected Available Inventory = Expected on hand inventory Planned Order Receipts = Planned quantity and arrival time of orders not yet placed Planned Order Releases = Planned quantity and time of order placement 7 8

Step by Step Solution

3.43 Rating (159 Votes )

There are 3 Steps involved in it

Salution m mo 1 Since mass is variable wrt ... View full answer

Get step-by-step solutions from verified subject matter experts