Question

Read the case below, provide a sound and critical argument highlighting where you expect to find space for process improvement. Background Stonehaven, Inc., headquartered near

Read the case below, provide a sound and critical argument highlighting where you expect to find space for process improvement.

Background

Stonehaven, Inc., headquartered near Boston, is a major manufacturer of popular brand name non-athletic shoes for adults. Its shoes are sold primarily in the U.S. market; because of sizable cost benefits, however, most shoe production takes place in factories in Asia and Eastern Europe, and management is not considering any change in this policy.

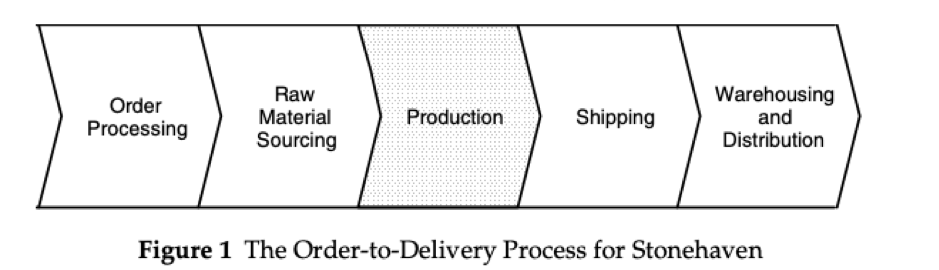

The market has become increasingly fashion conscious, resulting in proliferation of shoe designs and growing uncertainty in the demand for each style. Management has determined that it is necessary to improve the company's response to unexpected demand fluctuations by tackling the long order-to-delivery lead times, starting with production throughput time.

Recently, a team of bright students from a well-known Eastern U.S. business school visited one of Stonehaven's small factories in Gdansk, Poland. On their return, they expressed the opinion that throughput time could indeed be dramatically reduced.

The Production System

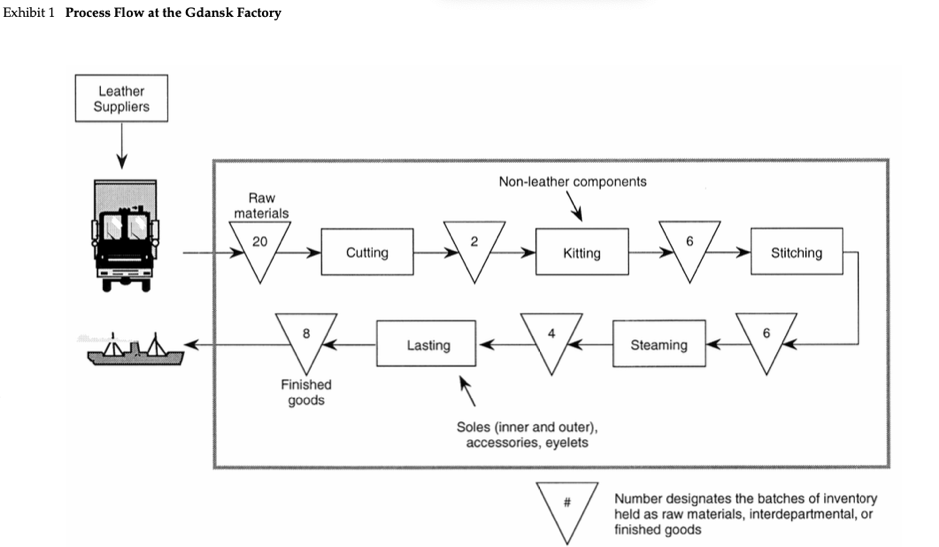

Stonehaven's Gdansk, Poland factory currently operates at capacity, running eight hours per day, five days per week. After the kitting step (described later), shoes pass from department to department in batches of 100 pairs. Each batch is homogeneous that is, each pair in a batch is exactly the same style, size, and color. Generally, no two consecutive batches are identical. Each department is responsible for the quality of its work.

Cutting

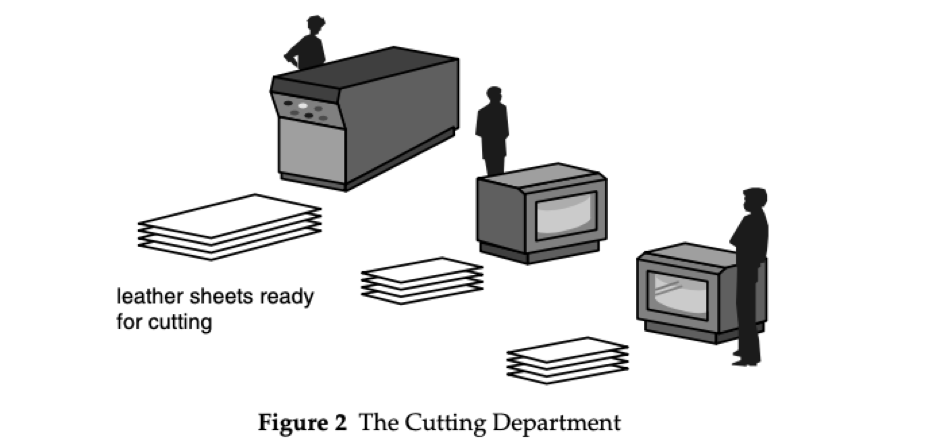

In the cutting department, individual leather hides are cut into the component pieces for shoe "uppers" the leather components that comprise the shoe above the sole. Each pair of shoes requires 12 distinct components six for the left shoe and six for the right. Each of three stamping presses in the cutting department performs a different set of cutting operations; each press cuts four of the 12 components.

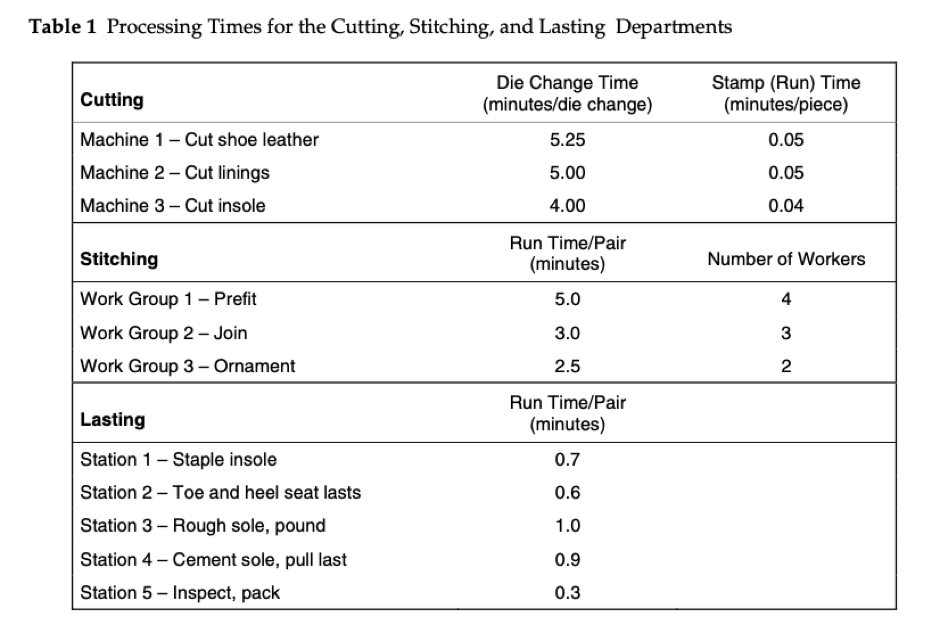

For any particular style and size, there are "dies" or cutting templates that cut the leather into the shape of a single component. The die on each stamping press must be changed to cut different component shapes. Thus, to cut 4 components for a 100-pair batch, a stamping machine must be set up four times. To obtain quality components, the operator cuts one leather sheet at a time. Setup times (die change) and run times (for a single stamping plus loading and unloading) are shown in Table 1.

The cutting department works on only one batch at a time. Work on a batch is carried on simultaneously on all three stamping presses and requires a full-time operator for each press. When all the components required for a batch have been cut, they are transferred out of the department and work begins on the next batch.

Kitting Department

In the kitting department, an "assembly kit" is put together for each batch of shoes; each kit contains the cut leather pieces (12 components 100) and most other materials required for assembly of the 100 pairs in that batch. (A few components used at the lasting stage are not included; these are directly supplied to the lasting department.) The entire kit is moved from department to department, and within the stitching and steaming departments, in a basket. Each basket is marked with a date and a unique serial number indicating style, size, and color for purposes of identification and instructions to materials handlers and operators. The rationale for this design was to simplify the information flows within the factory.

The time taken for kitting a batch is about 10 minutes. Except for the batch being worked on, no inventory is held within the kitting department.

Stitching

The six components of each left and right shoe upper are stitched together in the stitching department. There are three distinct stitching operations: prefitting, joining, and ornamenting. Table 1 shows the number of workers assigned to each operation and the associated processing times. No setups are required in this department.

The department uses a conveyor system designed to allow for a two-way flow of baskets (kits). A department supervisor is positioned at one end of the conveyors, and the workers and their sewing machines are located along the length of the conveyors. While a worker stitches the shoes from one kit, a second kit is kept alongside as inventory. When a worker is finished with a kit, it is sent back along the conveyor to the supervisor, and the worker then starts working on the second kit. The supervisor will send the worker another kit as soon as one is available; it then becomes the inventory buffer for that worker. Because of different times required for different sets of operations, there may be periods when one or more of the workers are idle.

Kits never pass directly from one worker to another each worker only receives kits from, and sends kits to, the department supervisor. Since three operations must be performed on each pair of shoes, each kit makes three round trips on the conveyors. When a batch is finished with all of the stitching operations, the supervisor transfers it out of the department and brings in a new batch, ready for stitching.

Steaming

Shoe uppers are steamed in a large oven for 6 hours to make the leather pliable for the lasting operation. Baskets pass through the oven on a conveyor belt, going in one end and emerging from the other. The oven has significant excess capacity and so batches never have to wait for space in the oven.

Lasting

In the lasting department, the stitched uppers are attached to the sole and the completed shoes are inspected, packed, and readied for shipping. (The "last" is a wooden form in the shape of a foot.) In the lasting department, shoes are not carried in kits; each kit is separated into individual pairs as it enters the department. The setup time required for each kit (including the time required to separate kits into individual pairs) is negligible.

All operations in the lasting department are performed along a conveyor line designed to move at a rate that matches the operators' work standards. There are five stations and five operators along the conveyor (see Table 1 for processing time data). Until all the shoes in a batch have been packed, a new batch is not placed onto the conveyor.

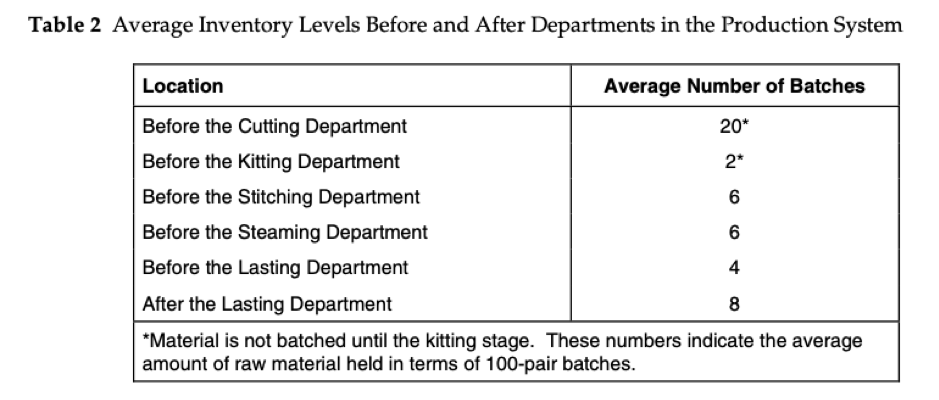

Inventories

Raw material, finished goods, and interdepartmental inventories are maintained in the factory, as described in Table 2.

1. According to the case study, what does management want to achieve? (2 points)

2. In the original Stonehaven Case, if batch size is reduced to 35 pairs, what would be the unconstrained cycle time of the Cutting Department? (4 points)

3. In the original Stonehaven Case, if batch size is reduced to 35 pairs, what would be the Capacity of the Cutting Department? (2 points)

4. In the original Stonehaven Case, what is the minimum (theoretical) MTT for the Stitching Department when batch size is reduced to 60 pairs? (4 points)

5. In the original Stonehaven Case, what is the Department Cycle Time (CT) for the Stitching Department when batch size is reduced to 60 pairs? (4 points)

6. In the original Stonehaven Case, for inventory (L) in the Stitching Department, each worker has 2 kits, one that they are stitching and one they have as inventory (Stonehaven, pg 3) (1 kit = 1 batch) Assuming 60 pairs as a batch, using Littles Law, what is the TPT (W)? (4 points)

7. In the original Stonehaven Case, what is the Stitching Department capacity in Batches per day (assume 60 pairs in a batch)? (2 points)

8. In the original Stonehaven Case, what is the Stitching Department capacity in pairs per day (assume 60 pairs in a batch)? (2 points)

9. In the original Stonehaven Case, the Lasting Department is a paced line conveyor, designed to move at a rate that matches the operators work standards (Stonehaven, pg 3). What is the Cycle Time (CT) for 1 batch when batch size is reduced to 60 pairs? (2 points)

10. In the original Stonehaven case, using a batch size of 60, what is the capacity of the Lasting Department? (2 points)

11. In the original Stonehaven case, using a batch size of 60, what is the capacity of the Lasting Department in pairs of shoes per day? (2 points)

12. In the original Stonehaven Case, if batch size is reduced to 60 pairs what would the factory capacity be in pairs of shoes? Hint - You have calculated the Cycle Time (CT) for both the Stitching Department and the Lasting Department already, the case provides the CT for the Kitting Department, and the Steaming Department has enough capacity that it is not a factor. Assume the Cycle Time (CT) for the Cutting Department is 33 min per batch. What is the factory Capacity in pairs per day? (4 points)

13. Using the Factory Cycle Time you calculated in problem #12 What is the WIP inventory (L) in the Lasting Department? Hint: Use Littles Law: L (department) = W (department time) / CT (factory) (3 points)

14. In the original Stonehaven Case, how much inventory (in batches) is located between the departments in Stonehaven? (i.e. How much WIP inventory?) (3 points)

Table 1 Processing Times for the Cutting, Stitching, and Lasting Departments Table 2 Average Inventory Levels Before and After Departments in the Production System Figure 1 The Order-to-Delivery Process for Stonehaven Figure 2 The Cutting Department Exhibit 1 Process Flow at the Gdansk FactoryStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started