Answered step by step

Verified Expert Solution

Question

1 Approved Answer

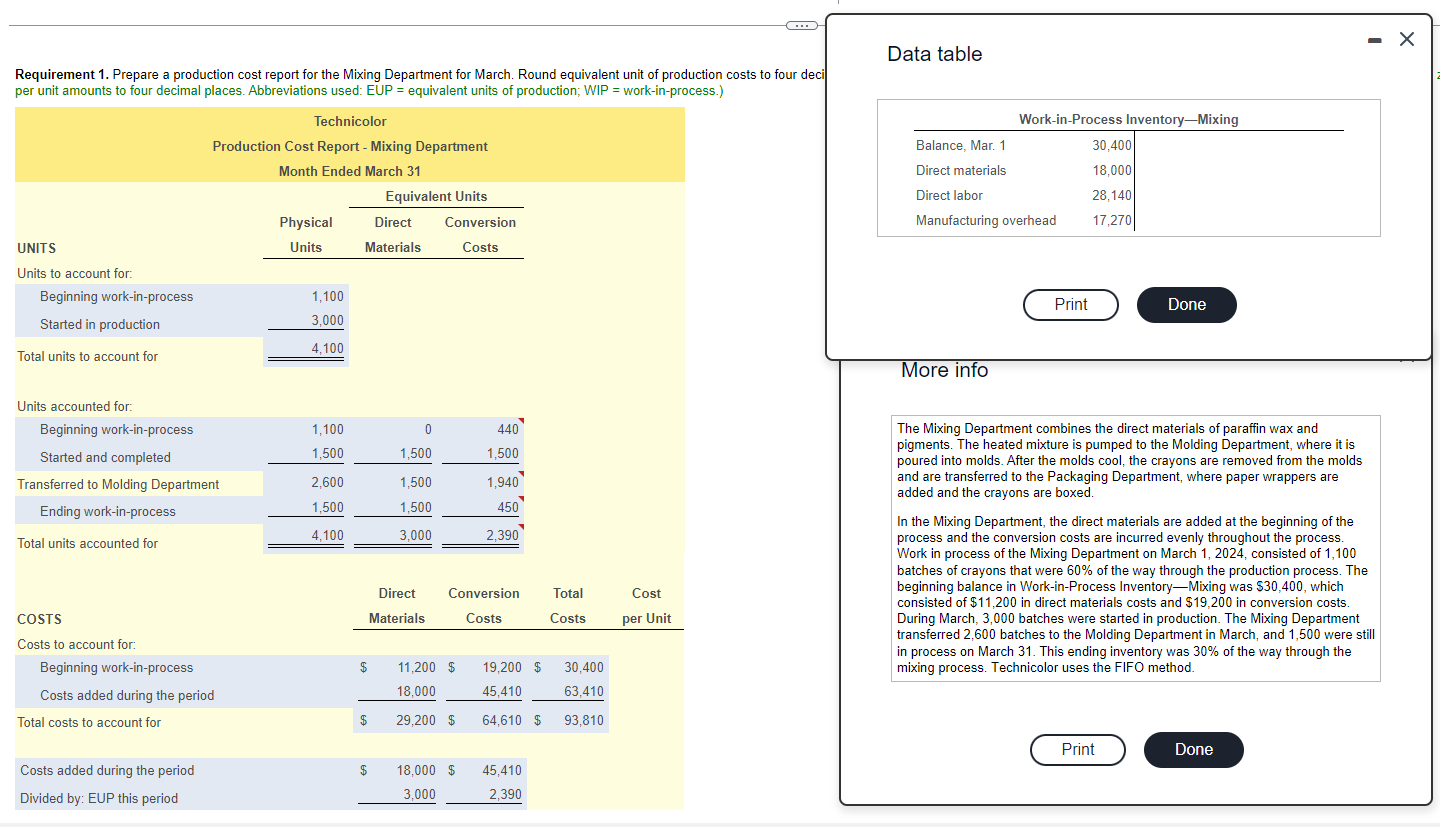

Requirement 1. Prepare a production cost report for the Mixing Department for March. Round equivalent unit of production costs to four deci per unit

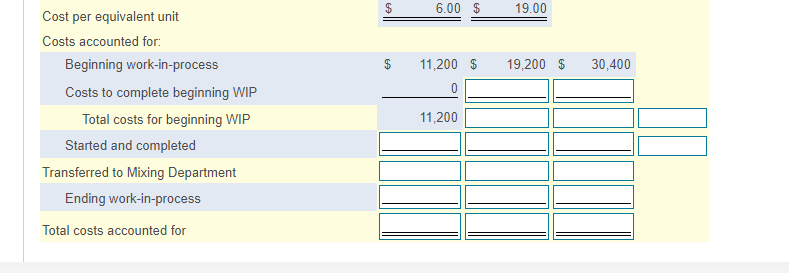

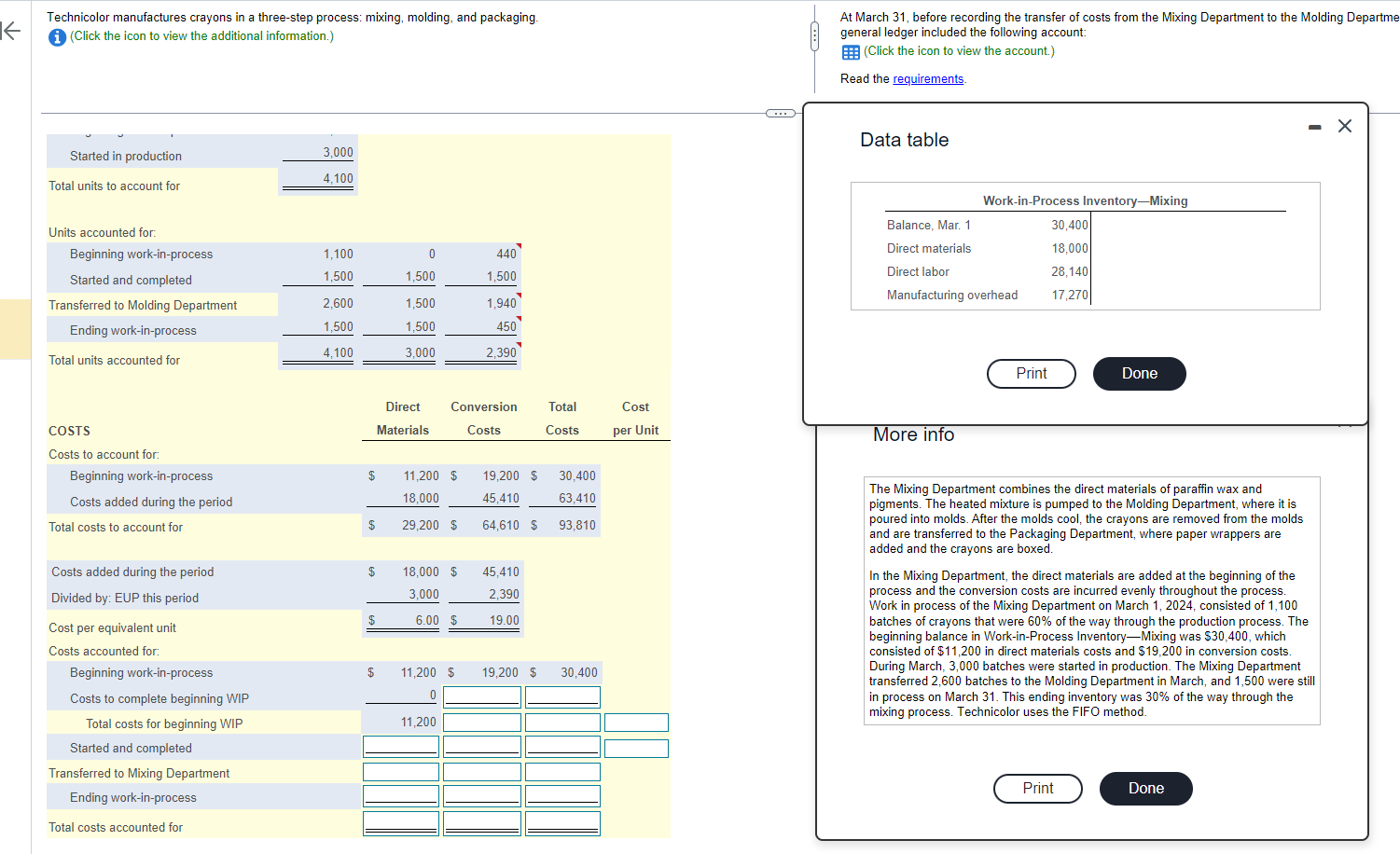

Requirement 1. Prepare a production cost report for the Mixing Department for March. Round equivalent unit of production costs to four deci per unit amounts to four decimal places. Abbreviations used: EUP = equivalent units of production; WIP = work-in-process.) Technicolor Production Cost Report - Mixing Department Month Ended March 31 Equivalent Units Data table UNITS Physical Direct Conversion Units Materials Costs Units to account for: Beginning work-in-process 1,100 Started in production 3,000 4,100 Total units to account for Units accounted for: Beginning work-in-process 1,100 440 Started and completed 1,500 1,500 1,500 Transferred to Molding Department 2,600 1,500 1,940 Ending work-in-process 1,500 1,500 450 4,100 3,000 2,390 Total units accounted for COSTS Direct Materials Conversion Costs Total Costs Costs to account for: Beginning work-in-process Costs added during the period 11,200 $ 18,000 19,200 $ 45,410 30,400 63,410 Total costs to account for $ 29,200 $ 64,610 $ 93,810 Costs added during the period Divided by: EUP this period 18,000 $ 3,000 45,410 2,390 Work-in-Process Inventory-Mixing Balance, Mar. 1 Direct materials 30,400 18,000 Direct labor 28,140 Manufacturing overhead 17,270 More info Print Done Cost per Unit The Mixing Department combines the direct materials of paraffin wax and pigments. The heated mixture is pumped to the Molding Department, where it is poured into molds. After the molds cool, the crayons are removed from the molds and are transferred to the Packaging Department, where paper wrappers are added and the crayons are boxed. In the Mixing Department, the direct materials are added at the beginning of the process and the conversion costs are incurred evenly throughout the process. Work in process of the Mixing Department on March 1, 2024, consisted of 1,100 batches of crayons that were 60% of the way through the production process. The beginning balance in Work-in-Process Inventory-Mixing was $30,400, which consisted of $11,200 in direct materials costs and $19,200 in conversion costs. During March, 3,000 batches were started in production. The Mixing Department transferred 2,600 batches to the Molding Department in March, and 1,500 were still in process on March 31. This ending inventory was 30% of the way through the mixing process. Technicolor uses the FIFO method. Print Done A 6.00 19.00 Cost per equivalent unit Costs accounted for: Beginning work-in-process Costs to complete beginning WIP Total costs for beginning WIP Started and completed Transferred to Mixing Department Ending work-in-process Total costs accounted for $ 11,200 $ 19,200 $ 30,400 0 11,200 K Technicolor manufactures crayons in a three-step process: mixing, molding, and packaging. (Click the icon to view the additional information.) 3,000 Started in production 4,100 Total units to account for Units accounted for: Beginning work-in-process 1,100 440 Started and completed 1,500 1,500 1,500 Transferred to Molding Department 2,600 1,500 1,940 Ending work-in-process 1,500 1,500 450 4,100 3,000 2,390 Total units accounted for COSTS Direct Conversion Total Materials Costs Cost Costs per Unit Costs to account for: Beginning work-in-process $ Costs added during the period 11,200 $ 18,000 19,200 $ 45,410 30,400 63,410 Total costs to account for 29,200 $ 64,610 $ 93,810 At March 31, before recording the transfer of costs from the Mixing Department to the Molding Departme general ledger included the following account: (Click the icon to view the account.) Read the requirements. Data table Work-in-Process Inventory-Mixing Balance, Mar. 1 30,400 Direct materials 18,000 Direct labor 28,140 Manufacturing overhead 17,270 More info Print Done 11,200 $ 19,200 $ 30,400 11,200 The Mixing Department combines the direct materials of paraffin wax and pigments. The heated mixture is pumped to the Molding Department, where it is poured into molds. After the molds cool, the crayons are removed from the molds and are transferred to the Packaging Department, where paper wrappers are added and the crayons are boxed. In the Mixing Department, the direct materials are added at the beginning of the process and the conversion costs are incurred evenly throughout the process. Work in process of the Mixing Department on March 1, 2024, consisted of 1,100 batches of crayons that were 60% of the way through the production process. The beginning balance in Work-in-Process Inventory-Mixing was $30,400, which consisted of $11,200 in direct materials costs and $19,200 in conversion costs. During March, 3,000 batches were started in production. The Mixing Department transferred 2,600 batches to the Molding Department in March, and 1,500 were still in process on March 31. This ending inventory was 30% of the way through the mixing process. Technicolor uses the FIFO method. Costs added during the period 18,000 $ 45,410 Divided by: EUP this period 3,000 2,390 6.00 $ 19.00 Cost per equivalent unit Costs accounted for: Beginning work-in-process $ Costs to complete beginning WIP Total costs for beginning WIP Started and completed Transferred to Mixing Department Ending work-in-process Total costs accounted for Print Done

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Based on the given data heres the Production Cost Report for the Mixing Department for March Descrip...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started