Question

Requirements: 7.1 Compute the cost allocation rate for each activity. 7.2 Use the activity-based cost allocation rates to compute the indirect cost of each unit

Requirements: 7.1 Compute the cost allocation rate for each activity. 7.2 Use the activity-based cost allocation rates to compute the indirect cost of each unit of Ken and Fork-Knife. (Hint: Compute the total activity costs allocated to each product line and then compute the cost per unit.) 7.3 Clarkson's original single-allocation-base costing system allocated indirect costs to products at $20 per labour hour. Ken requires 25,000 labour hours, while Fork-Knife requires 75,000 labour hours. Compute the total indirect costs allocated to Ken and Fork-Knife under the original system. Then, compute the indirect cost per unit for each product. 7.4 Compare the activity-based costs per unit to the costs from the simpler original system. How have the unit costs changed? Explain why the costs changed as they did. Do you think it is worthwhile to implement this system?

Image transcription text

Clarkson Toys devel0ps miniature knick—knacks using small" toys and electronics. Clarkson is constantly creating new mini toys to meet market trends. The market is very competitive, and Clarkson's competitors continue to introduce new products at low prices (sometimes lower than Clarkson). The small miniatures are made using very inexpensive materials in an automated production line and therefore their largest cost tends to be overhead based. Clarkson recently hired Jennifer Card, a recent accounting graduate. Jennifer is eager to use her accounting knowledge from her favourite class, ACCT2011. Jennifer asked the Product Development Department Managerlohn House to join her in a pilot activity-based costing study. Jennifer and John identified the following activities, related costs, and cost allocation bases: 3 Estimated indirect activity costs Allocated base Estimated quantity of allocation base Product development 1,950,000 _ _ 12 new products Production machine 4,550,000 ' Machine hours 3,500,000 hours hours ' 1 Product testing 1,582,400 Quality control 184,000 hours testing hours _ ' Clarkson is planning to develop the following new toys: - A "Ken" talking action figures. The ken doll signs the signature song "I'm not Pete" - Limited edition character models from the original action game Fork-Knife. The game recently held a publicity stunt to bring back the original characters. These characters are very intricate and detailed. Ken requires 3 machine hours each as well as 2.5 hours of testing, while Fork-Knife requires 8 hours of machining and only 0.5 hours of testing. Clarkson expects production of Ken to be the normal level of 25,000 units, while Fork-Knife is anticipating to produce 50% more than normal.

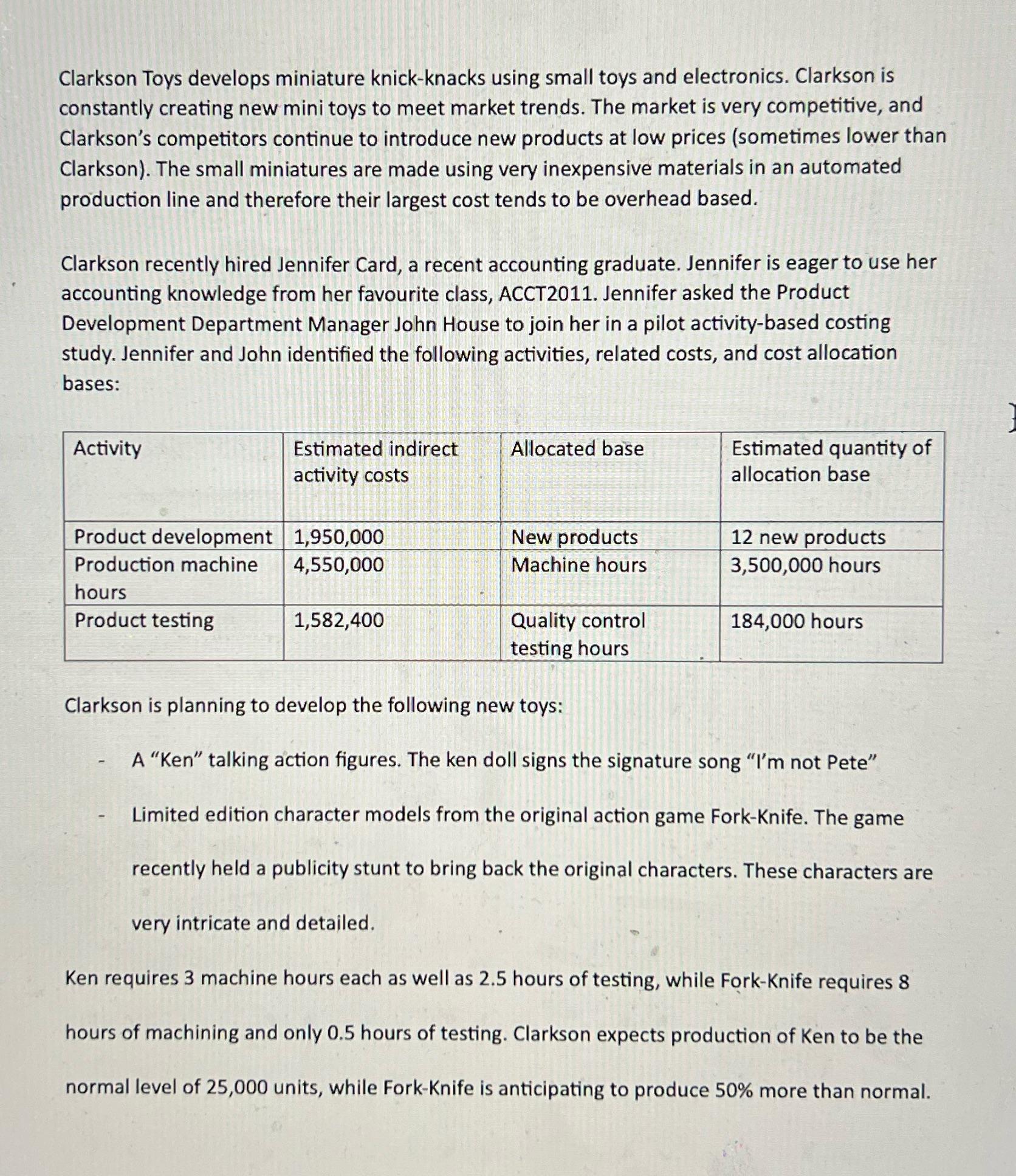

Clarkson Toys develops miniature knick-knacks using small toys and electronics. Clarkson is constantly creating new mini toys to meet market trends. The market is very competitive, and Clarkson's competitors continue to introduce new products at low prices (sometimes lower than Clarkson). The small miniatures are made using very inexpensive materials in an automated production line and therefore their largest cost tends to be overhead based. Clarkson recently hired Jennifer Card, a recent accounting graduate. Jennifer is eager to use her accounting knowledge from her favourite class, ACCT2011. Jennifer asked the Product Development Department Manager John House to join her in a pilot activity-based costing study. Jennifer and John identified the following activities, related costs, and cost allocation bases: Activity Estimated indirect activity costs Allocated base Estimated quantity of allocation base Product development 1,950,000 Production machine 4,550,000 hours Product testing 1,582,400 New products Machine hours 12 new products 3,500,000 hours Quality control testing hours 184,000 hours Clarkson is planning to develop the following new toys: - A "Ken" talking action figures. The ken doll signs the signature song "I'm not Pete" - Limited edition character models from the original action game Fork-Knife. The game recently held a publicity stunt to bring back the original characters. These characters are very intricate and detailed. Ken requires 3 machine hours each as well as 2.5 hours of testing, while Fork-Knife requires 8 hours of machining and only 0.5 hours of testing. Clarkson expects production of Ken to be the normal level of 25,000 units, while Fork-Knife is anticipating to produce 50% more than normal.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started