Review the attachments

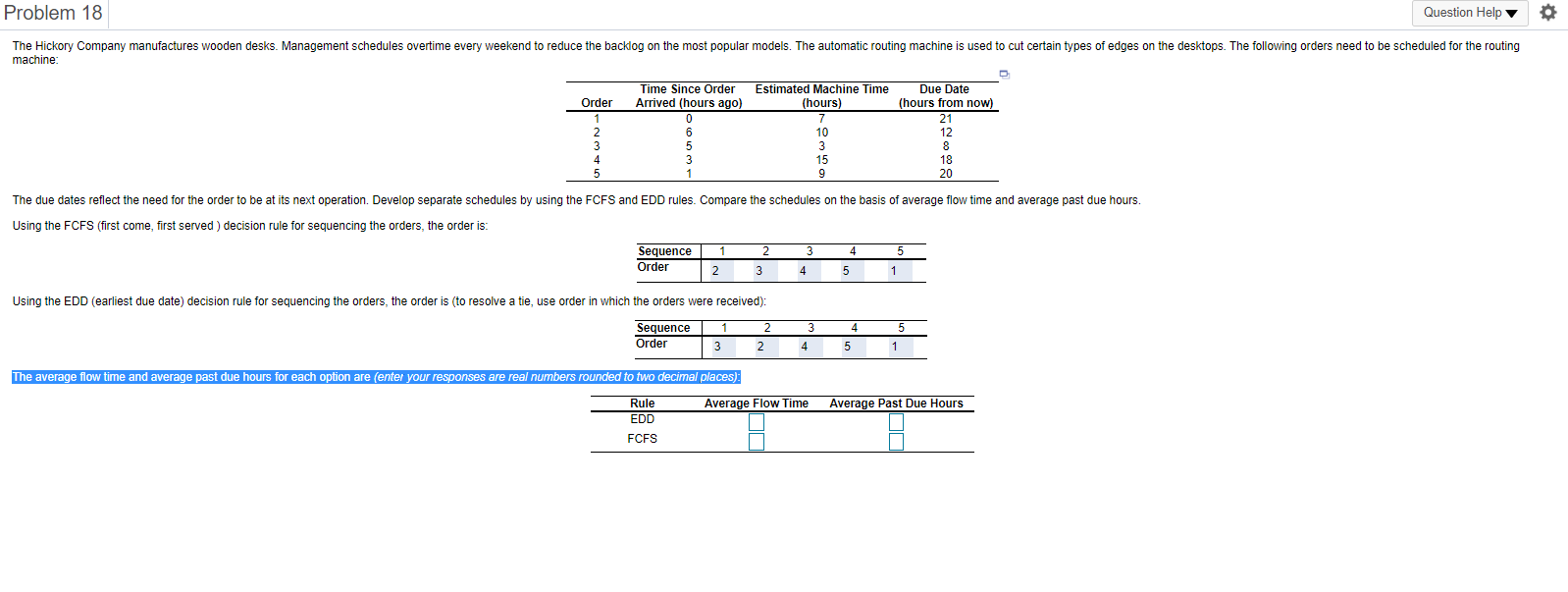

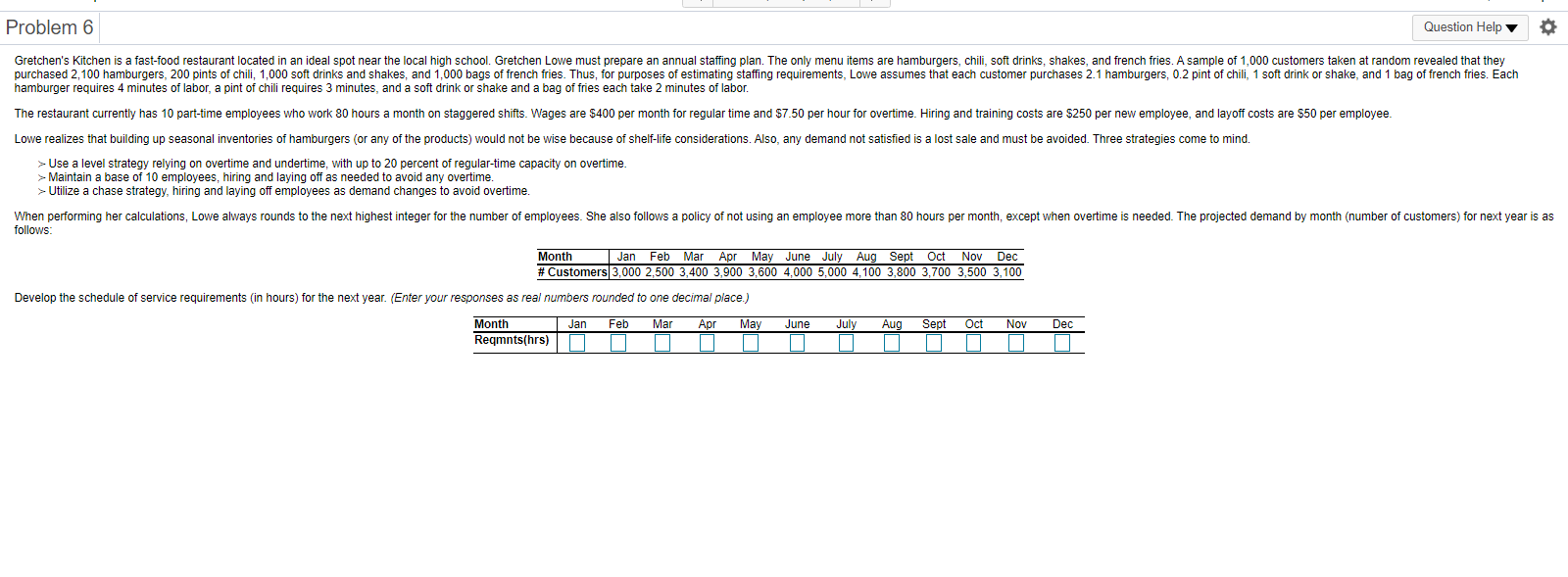

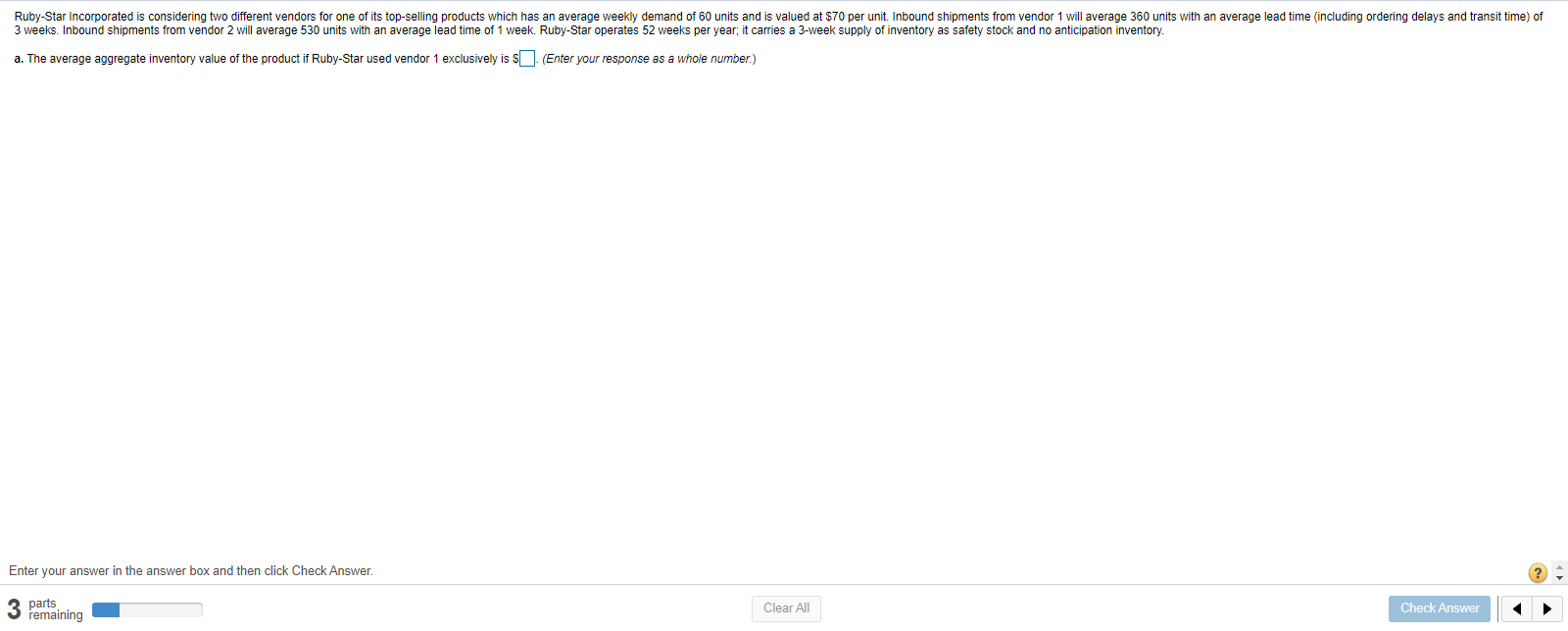

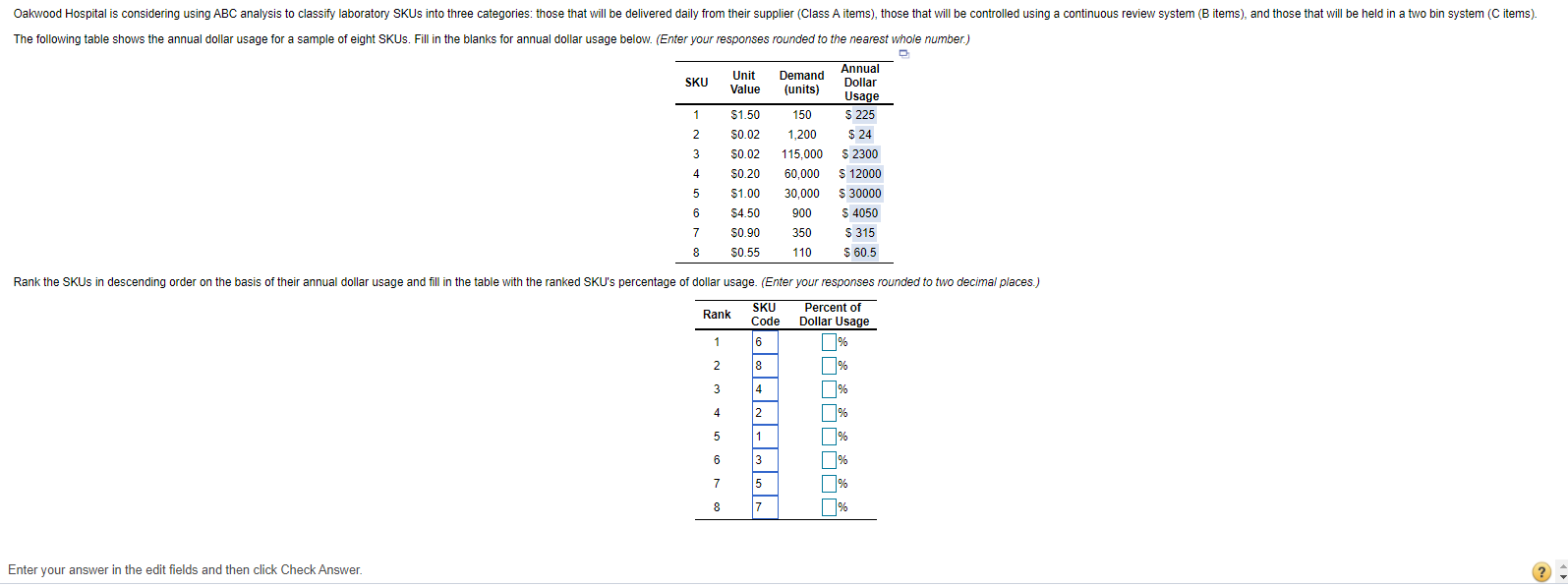

Problem 18 Question Help The Hickory Company manufactures wooden desks. Management schedules overtime every weekend to reduce the backlog on the most popular models. The automatic routing machine is used to cut certain types of edges on the desktops. The following orders need to be scheduled for the routing machine: Time Since Order Estimated Machine Time Due Date Order Arrived (hours ago) hours) (hours from now) 21 VIA WN 18 20 The due dates reflect the need for the order to be at its next operation. Develop separate schedules by using the FCFS and EDD rules. Compare the schedules on the basis of average flow time and average past due hours. Using the FCFS (first come, first served ) decision rule for sequencing the orders, the order is: Sequence 2 3 4 5 Orde 2 3 4 5 Using the EDD (earliest due date) decision rule for sequencing the orders, the order is (to resolve a tie, use order in which the orders were received): Sequence 3 4 Order 3 2 4 5 1 The average flow time and average past due hours for each option are (enter your responses are real numbers rounded to two decimal places): Rule Average Flow Time Average Past Due Hours EDD FCFSProblem 6 Question Help Gretchen's Kitchen is a fast-food restaurant located in an ideal spot near the local high school. Gretchen Lowe must prepare an annual staffing plan. The only menu items are hamburgers, chili, soft drinks, shakes, and french fries. A sample of 1,000 customers taken at random revealed that they purchased 2, 100 hamburgers, 200 pints of chili, 1,000 soft drinks and shakes, and 1,000 bags of french fries. Thus, for purposes of estimating staffing requirements, Lowe assumes that each customer purchases 2.1 hamburgers, 0.2 pint of chili, 1 soft drink or shake, and 1 bag of french fries. Each hamburger requires 4 minutes of labor, a pint of chili requires 3 minutes, and a soft drink or shake and a bag of fries each take 2 minutes of labor. The restaurant currently has 10 part-time employees who work 80 hours a month on staggered shifts. Wages are $400 per month for regular time and $7.50 per hour for overtime. Hiring and training costs are $250 per new employee, and layoff costs are $50 per employee. Lowe realizes that building up seasonal inventories of hamburgers (or any of the products) would not be wise because of shelf-life considerations. Also, any demand not satisfied is a lost sale and must be avoided. Three strategies come to mind. > Use a level strategy relying on overtime and undertime, with up to 20 percent of regular-time capacity on overtime. > Maintain a base of 10 employees, hiring and laying off as needed to avoid any overtime > Utilize a chase strategy, hiring and laying off employees as demand changes to avoid overtime. When performing her calculations, Lowe always rounds to the next highest integer for the number of employees. She also follows a policy of not using an employee more than 80 hours per month, except when overtime is needed. The projected demand by month (number of customers) for next year is as follows: Month Jan Feb Mar May June July A Sept Nov # Customers 3,000 2,500 3,400 3,900 3,600 4,000 5,000 4, 100 3,800 3,700 3,500 3, 100 Develop the schedule of service requirements (in hours) for the next year. (Enter your responses as real numbers rounded to one decimal place.) Month Jan Feb Mar Apr May June July Aug Sept Oct Nov Dec Reqmnts(hrs) ORuby-Star Incorporated is considering two different vendors for one of its top-selling products which has an average weekly demand of 60 units and is valued at $70 per unit. Inbound shipments from vendor 1 will average 360 units with an average lead time (including ordering delays and transit time) of 3 weeks. Inbound shipments from vendor 2 will average 530 units with an average lead time of 1 week. Ruby-Star operates 52 weeks per year; it carries a 3-week supply of inventory as safety stock and no anticipation inventory. a. The average aggregate inventory value of the product if Ruby-Star used vendor 1 exclusively is $| |. (Enter your response as a whole number.) Enter your answer in the answer box and then click Check Answer. ? 3 parts Clear All remaining Check AnswerOakwood Hospital is considering using ABC analysis to classify laboratory SKUs into three categories: those that will be delivered daily from their supplier (Class A items), those that will be controlled using a continuous review system (B items), and those that will be held in a two bin system (C items). The following table shows the annual dollar usage for a sample of eight SKUs. Fill in the blanks for annual dollar usage below. (Enter your responses rounded to the nearest whole number.) Annual SKU Unit Demand Dollar Value (units) Usage $1.50 150 $ 225 N - $0.02 1,200 $ 24 $0.02 115,000 $ 2300 A W $0.20 60,000 $ 12000 $1.00 30,000 $ 30000 $4.50 900 $ 4050 30.90 350 $ 315 $0.55 110 $ 60.5 Rank the SKUs in descending order on the basis of their annual dollar usage and fill in the table with the ranked SKU's percentage of dollar usage. (Enter your responses rounded to two decimal places.) Rank SKU Percent of Code Dollar Usage 6 CO N 79% W % - N + 79% YOUA CO Enter your answer in the edit fields and then click Check