Answered step by step

Verified Expert Solution

Question

1 Approved Answer

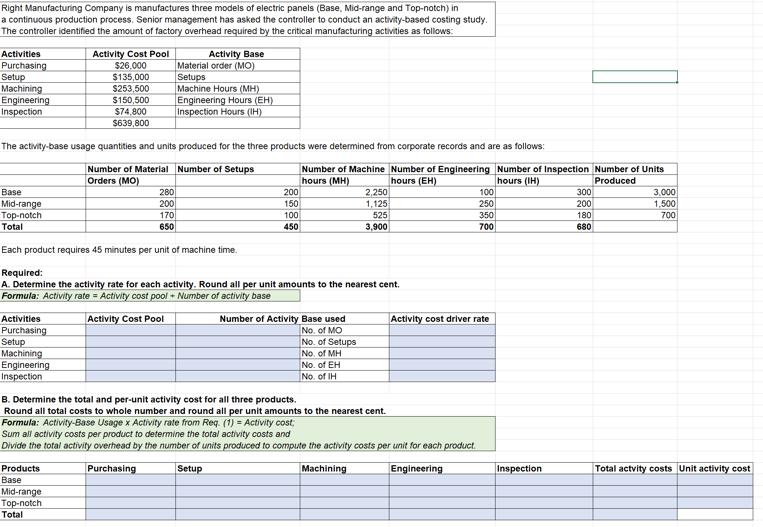

Right Manufacturing Company is manufactures three models of electric panels (Base, Mid-range and Top-notch) in a continuous production process. Senior management has asked the

Right Manufacturing Company is manufactures three models of electric panels (Base, Mid-range and Top-notch) in a continuous production process. Senior management has asked the controller to conduct an activity-based costing study. The controller identified the amount of factory overhead required by the critical manufacturing activities as follows: Activities Purchasing Setup Machining Engineering Inspection Base Mid-range Top-notch Total Activities Purchasing Activity Cost Pool $26,000 $135,000 $253,500 $150,500 Setup Machining Engineering Inspection $74,800 $639,800 The activity-base usage quantities and units produced for the three products were determined from corporate records and are as follows: Number of Material Number of Setups Orders (MO) Products Base Mid-range Top-notch Total Activity Base 280 200 170 650 Material order (MO) Setups Machine Hours (MH) Engineering Hours (EH) Inspection Hours (IH) 200 150 100 450 Each product requires 45 minutes per unit of machine time. Required: A. Determine the activity rate for each activity. Round all per unit amounts to the nearest cent. Formula: Activity rate= Activity cost pool+ Number of activity base Activity Cost Pool Number of Machine Number of Engineering Number of Inspection Number of Units hours (MH) hours (IH) Produced hours (EH) 2,250 1,125 525 3,900 Number of Activity Base used No. of MO No. of Setups No. of MH No. of EH No. of IH B. Determine the total and per-unit activity cost for all three products. Round all total costs to whole number and round all per unit amounts to the nearest cent. Formula: Activity-Base Usage x Activity rate from Req. (1) Activity cost; Sum all activity costs per product to determine the total activity costs and Divide the total activity overhead by the number of units produced to compute the activity costs per unit for each product. Purchasing Setup Machining Engineering 100 250 350 700 Activity cost driver rate Inspection 300 200 180 680 3,000 1,500 700 Total actvity costs Unit activity cost

Step by Step Solution

★★★★★

3.41 Rating (164 Votes )

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started