Answered step by step

Verified Expert Solution

Question

1 Approved Answer

PROBLEM 2 (Eliminating waste in processes) The JIT team in a company is evaluating lot sizes and setup time through the factory. The first

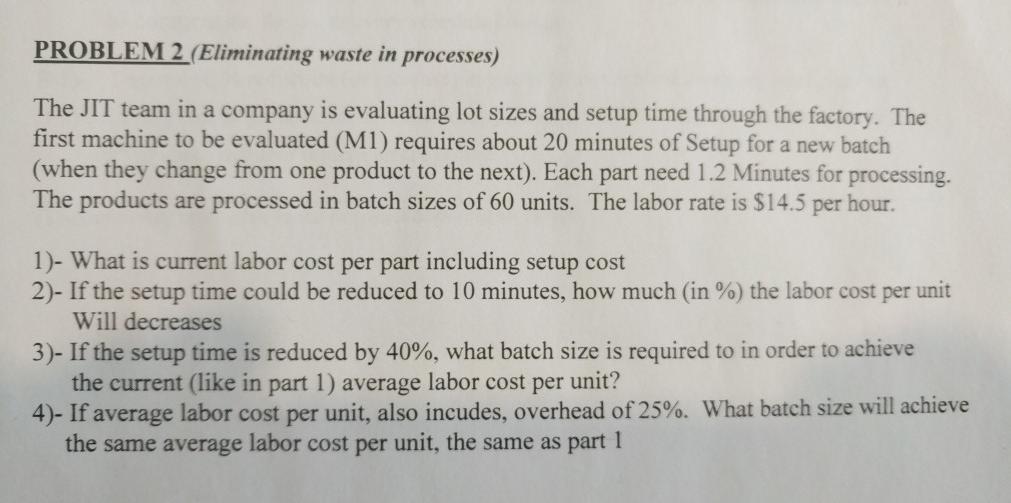

PROBLEM 2 (Eliminating waste in processes) The JIT team in a company is evaluating lot sizes and setup time through the factory. The first machine to be evaluated (M1) requires about 20 minutes of Setup for a new batch (when they change from one product to the next). Each part need 1.2 Minutes for processing. The products are processed in batch sizes of 60 units. The labor rate is $14.5 per hour. 1)- What is current labor cost per part including setup cost 2)- If the setup time could be reduced to 10 minutes, how much (in %) the labor cost per unit Will decreases 3)- If the setup time is reduced by 40%, what batch size is required to in order to achieve the current (like in part 1) average labor cost per unit? 4)- If average labor cost per unit, also incudes, overhead of 25%. What batch size will achieve the same average labor cost per unit, the same as part 1

Step by Step Solution

★★★★★

3.39 Rating (158 Votes )

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Document Format ( 2 attachments)

635dec7d70362_180015.pdf

180 KBs PDF File

635dec7d70362_180015.docx

120 KBs Word File

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started