Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Several years ago, Jan Northcutt, owner and CEO of Northcutt Bikes, saw the need to organize a separate department to deal with aftermarket parts for

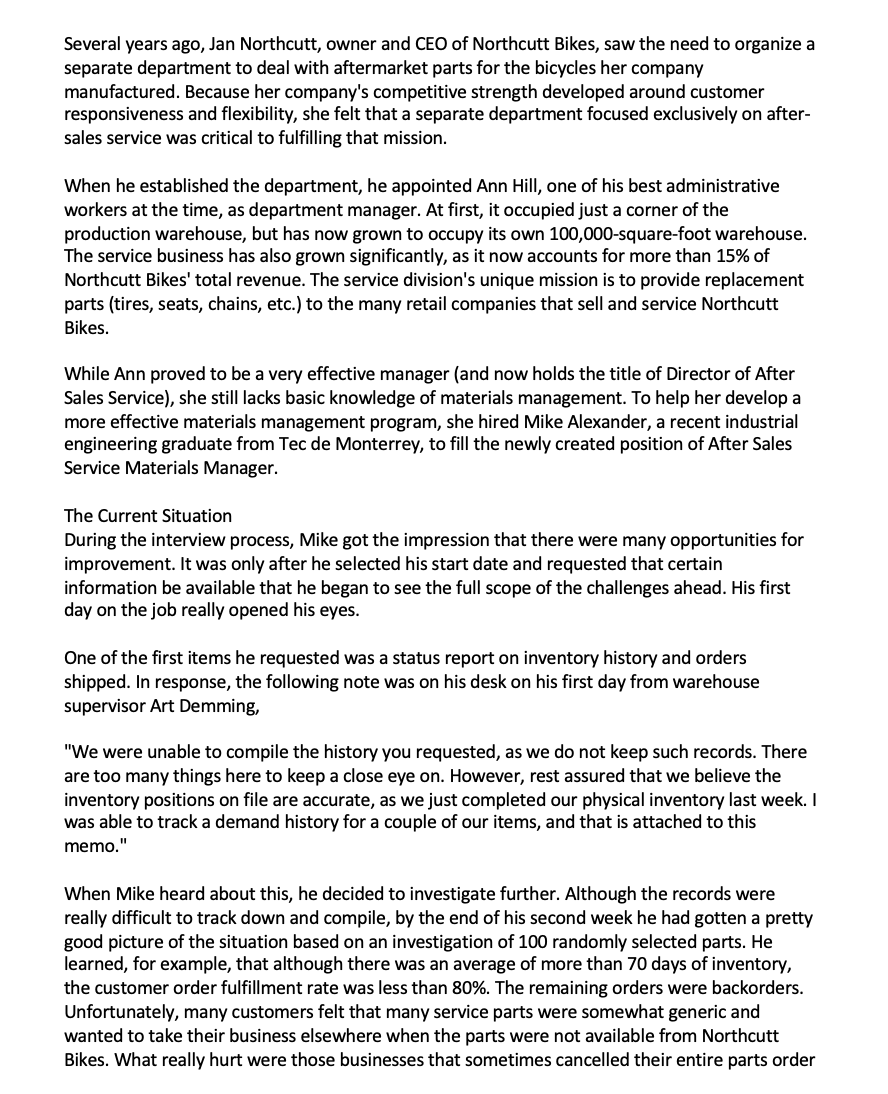

Several years ago, Jan Northcutt, owner and CEO of Northcutt Bikes, saw the need to organize a separate department to deal with aftermarket parts for the bicycles her company manufactured. Because her company's competitive strength developed around customer responsiveness and flexibility, she felt that a separate department focused exclusively on aftersales service was critical to fulfilling that mission. When he established the department, he appointed Ann Hill, one of his best administrative workers at the time, as department manager. At first, it occupied just a corner of the production warehouse, but has now grown to occupy its own 100,000-square-foot warehouse. The service business has also grown significantly, as it now accounts for more than 15% of Northcutt Bikes' total revenue. The service division's unique mission is to provide replacement parts (tires, seats, chains, etc.) to the many retail companies that sell and service Northcutt Bikes. While Ann proved to be a very effective manager (and now holds the title of Director of After Sales Service), she still lacks basic knowledge of materials management. To help her develop a more effective materials management program, she hired Mike Alexander, a recent industrial engineering graduate from Tec de Monterrey, to fill the newly created position of After Sales Service Materials Manager. The Current Situation During the interview process, Mike got the impression that there were many opportunities for improvement. It was only after he selected his start date and requested that certain information be available that he began to see the full scope of the challenges ahead. His first day on the job really opened his eyes. One of the first items he requested was a status report on inventory history and orders shipped. In response, the following note was on his desk on his first day from warehouse supervisor Art Demming, "We were unable to compile the history you requested, as we do not keep such records. There are too many things here to keep a close eye on. However, rest assured that we believe the inventory positions on file are accurate, as we just completed our physical inventory last week. I was able to track a demand history for a couple of our items, and that is attached to this memo." When Mike heard about this, he decided to investigate further. Although the records were really difficult to track down and compile, by the end of his second week he had gotten a pretty good picture of the situation based on an investigation of 100 randomly selected parts. He learned, for example, that although there was an average of more than 70 days of inventory, the customer order fulfillment rate was less than 80%. The remaining orders were backorders. Unfortunately, many customers felt that many service parts were somewhat generic and wanted to take their business elsewhere when the parts were not available from Northcutt Bikes. What really hurt were those businesses that sometimes cancelled their entire parts order and placed it with another parts supplier. Customers cancelled an outstanding item about 15% of the time, and about 5% of the time they cancelled their entire order. Sometimes those customers were lost forever. Since the average customer order represented revenue of about $500, these cancellations had a fairly large impact. The obvious conclusion is that while there is plenty of inventory overall, the timing and quantities are off. Increasing inventory did not seem to be the answer, not only because of the large amount already held, but also because the warehouse space (built less than two years ago) had increased from being 45% utilized just after moving in to its current utilization of over 95%. Mike decided to begin his analysis and solution development on the two items for which Art had already provided a demand history. He felt that if he could analyze and correct any problems with those two parts, he could expand the analysis to most of the others. The two items on which he had history and concentrated his initial analysis were the FB378 fender bracket and the GS131 sprocket. Northcutt Bikes purchases the FB378 from a Brazilian source. Lead time has remained fairly consistent at three weeks, and the estimated cost of a purchase order for these parts is $35.00 per order. Currently, Northcutt Bikes uses an order lot size of 120 for the FB378. Northcutt Bikes pays $5.59 each for this part. The nature of this product is such that Northcutt Bikes is not offered quantity discounts. The GS131 part, on the other hand, is a newer product offered recently. It is produced for Northcutt Bikes by a machine shop in Nashville, Tennessee, which gives Northcutt Bikes a fairly reliable six-week lead time. The cost to order from the machine shop is only $15.00, and Northcutt Bikes currently orders 850 at a time. Northcutt Bikes buys the item for $12.85 each. As with FB378, no quantity discounts are offered. The service division is currently able to borrow funds at an interest rate of 9% and is achieving an annual return on assets of 19%. The new warehouse was built two years ago at a cost of $1.8 million and requires average annual expenditures of $160,000 for utilities, $76,000 for insurance and $85,000 for maintenance. There are 15 full-time employees at the warehouse, earning an average wage of $20 per hour, including benefits. All of this translates into what they estimate is an inventory cost of 24% per year. While some of the customers pick up their orders directly from Northcutt Bikes' service warehouse, more than 90% receive them. Northcutt Bikes contracts with a national delivery company to deliver orders. The average delivery cost is $12, which Northcutt Bikes adds to the customer's invoice. The supplier of the FB378 fender bracket recently approached Northcutt Bikes with an offer to sell the FB378 at a quantity discount. If Northcutt Bikes were to purchase 300 to 499 per order, their cost would be $5.55. Ordering 500 or more at a time would allow them to reduce the cost to $5.50. Up to this point, Northcutt Bikes has been reluctant to take advantage of the offer due to the cost of inventory and the potential impact on already limited warehouse space. The following is the demand information Art had given Mike for the FB378 fender bracket and aC121 enranknt. Mike realized that he also needed Ann's opinion on their outlook for the business. She indicated that she was convinced that, with better management, they should be able to utilize the existing warehouse for years to come, even with the projected growth of the business. Currently, however, she sees the situation as a crisis because, "...we are bursting at the seams with inventory. It's costing us a lot of profit, but our service level is very low at less than 80%. I would like to see us maintain a service level of 97% or better with no backorders, but we need to be able to do that with a net reduction in total inventory. What do you think, Mike, that we can do better? - Use available information to evaluate Northcutt's inventory management methods. Examine alternative approaches and recommend one. Be sure to include your analysis and a rationale for the recommendation. - Examine the implicit and explicit inventory policies described in the case and evaluate them. Develop a comprehensive inventory management strategy and show how it would apply for the two items detailed. - Do you think lost customer sales should be included as an inventory cost? How would such an inclusion impact the ordering policies you established in question 2

Several years ago, Jan Northcutt, owner and CEO of Northcutt Bikes, saw the need to organize a separate department to deal with aftermarket parts for the bicycles her company manufactured. Because her company's competitive strength developed around customer responsiveness and flexibility, she felt that a separate department focused exclusively on aftersales service was critical to fulfilling that mission. When he established the department, he appointed Ann Hill, one of his best administrative workers at the time, as department manager. At first, it occupied just a corner of the production warehouse, but has now grown to occupy its own 100,000-square-foot warehouse. The service business has also grown significantly, as it now accounts for more than 15% of Northcutt Bikes' total revenue. The service division's unique mission is to provide replacement parts (tires, seats, chains, etc.) to the many retail companies that sell and service Northcutt Bikes. While Ann proved to be a very effective manager (and now holds the title of Director of After Sales Service), she still lacks basic knowledge of materials management. To help her develop a more effective materials management program, she hired Mike Alexander, a recent industrial engineering graduate from Tec de Monterrey, to fill the newly created position of After Sales Service Materials Manager. The Current Situation During the interview process, Mike got the impression that there were many opportunities for improvement. It was only after he selected his start date and requested that certain information be available that he began to see the full scope of the challenges ahead. His first day on the job really opened his eyes. One of the first items he requested was a status report on inventory history and orders shipped. In response, the following note was on his desk on his first day from warehouse supervisor Art Demming, "We were unable to compile the history you requested, as we do not keep such records. There are too many things here to keep a close eye on. However, rest assured that we believe the inventory positions on file are accurate, as we just completed our physical inventory last week. I was able to track a demand history for a couple of our items, and that is attached to this memo." When Mike heard about this, he decided to investigate further. Although the records were really difficult to track down and compile, by the end of his second week he had gotten a pretty good picture of the situation based on an investigation of 100 randomly selected parts. He learned, for example, that although there was an average of more than 70 days of inventory, the customer order fulfillment rate was less than 80%. The remaining orders were backorders. Unfortunately, many customers felt that many service parts were somewhat generic and wanted to take their business elsewhere when the parts were not available from Northcutt Bikes. What really hurt were those businesses that sometimes cancelled their entire parts order and placed it with another parts supplier. Customers cancelled an outstanding item about 15% of the time, and about 5% of the time they cancelled their entire order. Sometimes those customers were lost forever. Since the average customer order represented revenue of about $500, these cancellations had a fairly large impact. The obvious conclusion is that while there is plenty of inventory overall, the timing and quantities are off. Increasing inventory did not seem to be the answer, not only because of the large amount already held, but also because the warehouse space (built less than two years ago) had increased from being 45% utilized just after moving in to its current utilization of over 95%. Mike decided to begin his analysis and solution development on the two items for which Art had already provided a demand history. He felt that if he could analyze and correct any problems with those two parts, he could expand the analysis to most of the others. The two items on which he had history and concentrated his initial analysis were the FB378 fender bracket and the GS131 sprocket. Northcutt Bikes purchases the FB378 from a Brazilian source. Lead time has remained fairly consistent at three weeks, and the estimated cost of a purchase order for these parts is $35.00 per order. Currently, Northcutt Bikes uses an order lot size of 120 for the FB378. Northcutt Bikes pays $5.59 each for this part. The nature of this product is such that Northcutt Bikes is not offered quantity discounts. The GS131 part, on the other hand, is a newer product offered recently. It is produced for Northcutt Bikes by a machine shop in Nashville, Tennessee, which gives Northcutt Bikes a fairly reliable six-week lead time. The cost to order from the machine shop is only $15.00, and Northcutt Bikes currently orders 850 at a time. Northcutt Bikes buys the item for $12.85 each. As with FB378, no quantity discounts are offered. The service division is currently able to borrow funds at an interest rate of 9% and is achieving an annual return on assets of 19%. The new warehouse was built two years ago at a cost of $1.8 million and requires average annual expenditures of $160,000 for utilities, $76,000 for insurance and $85,000 for maintenance. There are 15 full-time employees at the warehouse, earning an average wage of $20 per hour, including benefits. All of this translates into what they estimate is an inventory cost of 24% per year. While some of the customers pick up their orders directly from Northcutt Bikes' service warehouse, more than 90% receive them. Northcutt Bikes contracts with a national delivery company to deliver orders. The average delivery cost is $12, which Northcutt Bikes adds to the customer's invoice. The supplier of the FB378 fender bracket recently approached Northcutt Bikes with an offer to sell the FB378 at a quantity discount. If Northcutt Bikes were to purchase 300 to 499 per order, their cost would be $5.55. Ordering 500 or more at a time would allow them to reduce the cost to $5.50. Up to this point, Northcutt Bikes has been reluctant to take advantage of the offer due to the cost of inventory and the potential impact on already limited warehouse space. The following is the demand information Art had given Mike for the FB378 fender bracket and aC121 enranknt. Mike realized that he also needed Ann's opinion on their outlook for the business. She indicated that she was convinced that, with better management, they should be able to utilize the existing warehouse for years to come, even with the projected growth of the business. Currently, however, she sees the situation as a crisis because, "...we are bursting at the seams with inventory. It's costing us a lot of profit, but our service level is very low at less than 80%. I would like to see us maintain a service level of 97% or better with no backorders, but we need to be able to do that with a net reduction in total inventory. What do you think, Mike, that we can do better? - Use available information to evaluate Northcutt's inventory management methods. Examine alternative approaches and recommend one. Be sure to include your analysis and a rationale for the recommendation. - Examine the implicit and explicit inventory policies described in the case and evaluate them. Develop a comprehensive inventory management strategy and show how it would apply for the two items detailed. - Do you think lost customer sales should be included as an inventory cost? How would such an inclusion impact the ordering policies you established in question 2 Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started