Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Smart Electric Motor company assembles three types of electric motor. Assembly involves two major steps: winding the motor's armature and then assembling the completed

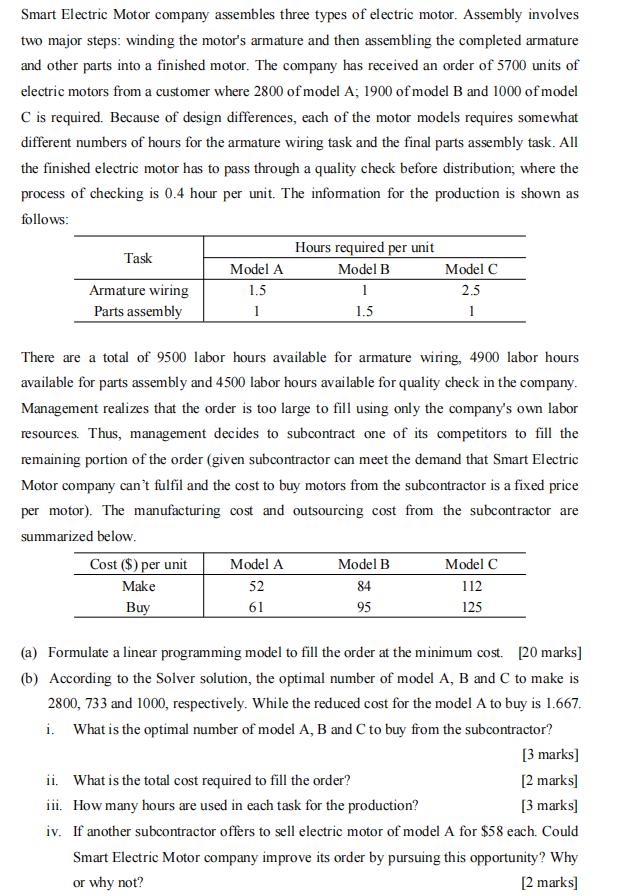

Smart Electric Motor company assembles three types of electric motor. Assembly involves two major steps: winding the motor's armature and then assembling the completed armature and other parts into a finished motor. The company has received an order of 5700 units of electric motors from a customer where 2800 of model A; 1900 of model B and 1000 of model C is required. Because of design differences, each of the motor models requires somewhat different numbers of hours for the armature wiring task and the final parts assembly task. All the finished electric motor has to pass through a quality check before distribution; where the process of checking is 0.4 hour per unit. The information for the production is shown as follows: Task Armature wiring Parts assembly Model A 1.5 1 Cost ($) per unit Make Buy Hours required per unit Model B Model A 52 61 1 1.5 There are a total of 9500 labor hours available for armature wiring, 4900 labor hours available for parts assembly and 4500 labor hours available for quality check in the company. Management realizes that the order is too large to fill using only the company's own labor resources. Thus, management decides to subcontract one of its competitors to fill the remaining portion of the order (given subcontractor can meet the demand that Smart Electric Motor company can't fulfil and the cost to buy motors from the subcontractor is a fixed price per motor). The manufacturing cost and outsourcing cost from the subcontractor are summarized below. Model C 2.5 1 Model B 84 95 Model C 112 125 (a) Formulate a linear programming model to fill the order at the minimum cost. [20 marks] (b) According to the Solver solution, the optimal number of model A, B and C to make is 2800, 733 and 1000, respectively. While the reduced cost for the model A to buy is 1.667. i. What is the optimal number of model A, B and C to buy from the subcontractor? [3 marks] [2 marks] ii. What is the total cost required to fill the order? iii. How many hours are used in each task for the production? [3 marks] iv. If another subcontractor offers to sell electric motor of model A for $58 each. Could Smart Electric Motor company improve its order by pursuing this opportunity? Why or why not? [2 marks]

Step by Step Solution

★★★★★

3.38 Rating (157 Votes )

There are 3 Steps involved in it

Step: 1

a Decision variables Number of model A made inhouse AM Number of model B made inhouse BM Number of m...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started