Answered step by step

Verified Expert Solution

Question

1 Approved Answer

solve BY CHRISTOPHER LEONARD ARKANSAS DEMOCRAT-GAZETTE KANSAS CITY, MO. - Gordon Beaham still remembers the visit he made to Bentonville about 20 years ago. Beaham,

solve

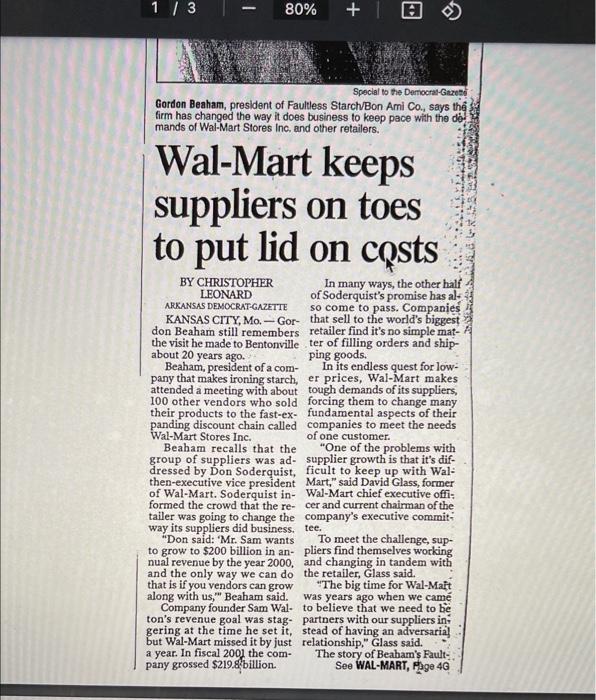

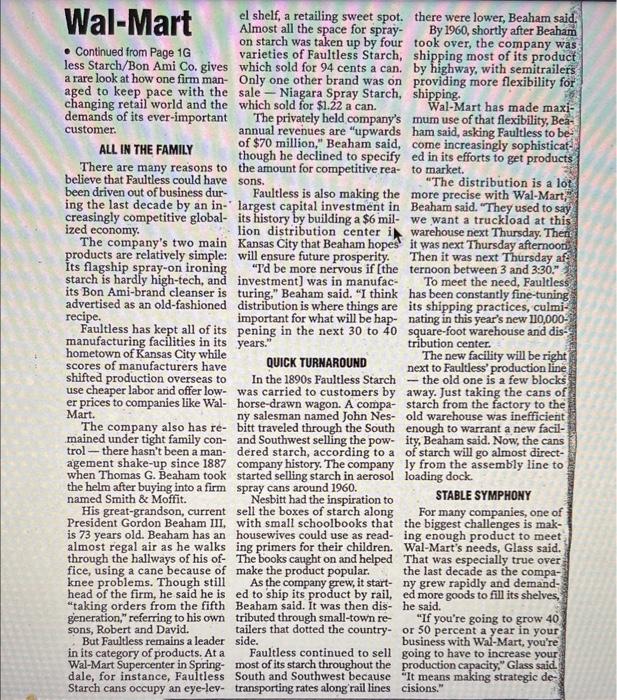

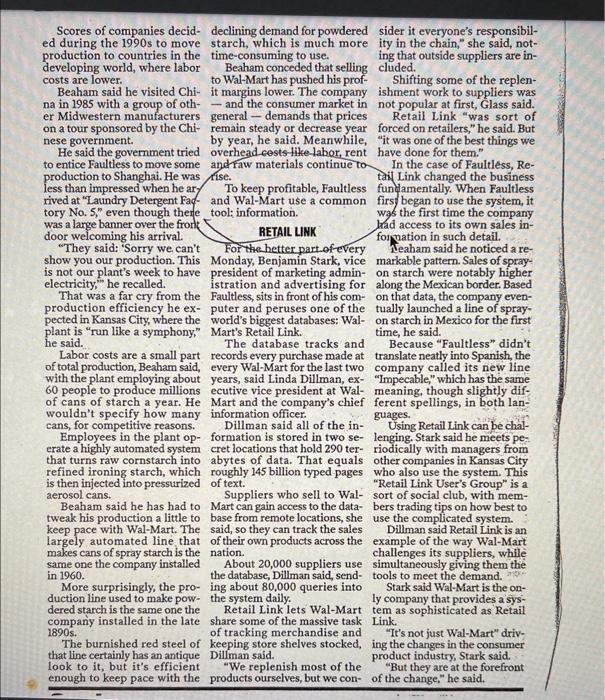

BY CHRISTOPHER LEONARD ARKANSAS DEMOCRAT-GAZETTE KANSAS CITY, MO. - Gordon Beaham still remembers the visit he made to Bentonville about 20 years ago. Beaham, president of a company that makes ironing starch, attended a meeting with about 100 other vendors who sold their products to the fast-expanding discount chain called Wal-Mart Stores Inc. Beaham recalls that the group of suppliers was addressed by Don Soderquist, then-executive vice president of Wal-Mart. Soderquist informed the crowd that the retailer was going to change the way its suppliers did business. "Don said: Mr. Sam wants to grow to $200 billion in annual revenue by the year 2000 . and the only way we can do that is if you vendors can grow along with us,"' Beaham said. Company founder Sam Walton's revenue goal was staggering at the time he set it, but Wal-Mart missed it by just a year. In fiscal 2001 the company grossed \$219.8billion. In many ways, the other half of Soderquist's promise has al. so come to pass. Companies that sell to the world's biggest retailer find it's no simple mat- A ter of filling orders and shipping goods. In its endless quest for low: er prices, Wal-Mart makes tough demands of its suppliers, forcing them to change many fundamental aspects of their companies to meet the needs of one customer. "One of the problems with supplier growth is that it's difficult to keep up with Wal: Mart," said David Glass, former Wal-Mart chief executive offi: cer and current chairman of the company's executive commit? tee. To meet the challenge, suppliers find themselves working and changing in tandem with the retailer, Glass said. "The big time for Wal-Maitt was years ago when we cam to believe that we need to be partners with our suppliers in: stead of having an adversarial relationship," Glass said. The story of Beaham's Fault:See WAL-MART, PAge 4G Wal-Mart - Continued from Page 1G less Starch/Bon Ami Co, gives a rare look at how one firm managed to keep pace with the changing retail world and the demands of its ever-important customer. ALL IN THE FAMILY There are many reasons to believe that Faultless could have been driven out of business during the last decade by an in-" creasingly competitive globalized economy. The company's two main products are relatively simple: Its flagship spray-on ironing starch is hardly high-tech, and its Bon Ami-brand cleanser is advertised as an old-fashioned recipe. Faultless has kept all of its manufacturing facilities in its hometown of Kansas City while scores of manufacturers have shifted production overseas to use cheaper labor and offer lower prices to companies like WalMart. The company also has remained under tight family control - there hasn't been a management shake-up since 1887 when Thomas G. Beaham took the helm after buying into a firm named Smith \& Moffit. His great-grandson, current President Gordon Beaham III, is 73 years old. Beaham has an almost regal air as he walks through the hallways of his office, using a cane because of knee problems. Though still head of the firm, he said he is "taking orders from the fifth generation," referring to his own sons, Robert and David. But Faultless remains a leader in its category of products. At a Wal-Mart Supercenter in Springdale, for instance, Faultess Starch cans occupy an eye-lev- el shelf, a retailing sweet spot. Almost all the space for sprayon starch was taken up by four varieties of Faultless Starch, which sold for 94 cents a can. Only one other brand was on sale - Niagara Spray Starch, which sold for $1.22 a can. The privately held company's annual revenues are "upwards of $70 million," Beaham said, though he declined to specify the amount for competitive reasons. Faultless is also making the largest capital investment in its history by building a $6mil lion distribution center is Kansas City that Beaham hopes will ensure future prosperity. "Id be more nervous if [the investment] was in manufacturing," Beaham said. "I think distribution is where things are important for what will be happening in the next 30 to 40 years." QUICK TURNAROUHD In the 1890s Faultless Starch was carried to customers by horse-drawn wagon. A company salesman named John Nesbitt traveled through the South and Southwest selling the powdered starch, according to a company history. The company started selling starch in aerosol spray cans around 1960. Nesbitt had the inspiration to sell the boxes of starch along with small schoolbooks that housewives could use as reading primers for their children. The books caught on and helped make the product popular. As the company grew, it started to ship its product by rail, Beaham said. It was then distributed through small-town retailers that dotted the countryside. Faultless continued to sell most of its starch throughout the South and Southwest because transporting rates along rail lines there were lower, Beaham said. By 1960, shortly after Beaham took over, the company was shipping most of its product by highway, with semitrailers providing more flexibility for shipping. Wal-Mart has made maximum use of that flexibility, Beaham said, asking Faultless to be come increasingly sophisticated in its efforts to get products to market. "The distribution is a lot more precise with Wal-Mart? Beaham said. "They used to say we want a truckload at this warehouse next Thursday. Then it was next Thursday afternoon Then it was next Thursday af ternoon between 3 and 3:30," To meet the need, Faultless has been constantly fine-tuning its shipping practices, culminating in this year's new 110,000 square-foot warehouse and distribution center. The new facility will be right next to Faultiess' production line - the old one is a few blocks away. Just taking the cans of starch from the factory to the old warehouse was inefficient enough to warrant a new facility, Beaham said. Now, the cans of starch will go almost directly from the assembly line to loading dock. STABLE SYMPHONY For many companies, one of the biggest challenges is making enough product to meet Wal-Mart's needs, Glass said. That was especially true over the last decade as the company grew rapidly and demanded more goods to fill its shelves, he said. "If you're going to grow 40 or 50 percent a year in your business with Wal-Mart, you're going to have to increase your production capacity," Glass said. "It means making strategic decisions." Scores of companies decided during the 1990 s to move production to countries in the developing world, where labor costs are lower. Beaham said he visited China in 1985 with a group of other Midwestern manufacturers on a tour sponsored by the Chinese government. He said the government tried to entice Faultless to move some production to Shanghai. He was less than impressed when he ar rived at "Laundry Detergent Faftory No. 5," even though there was a large banner over the front door welcoming his arrival. "They said: 'Sorry we can't show you our production. This is not our plant's week to have electricity," he recalled. That was a far cry from the production efficiency he expected in Kansas City, where the plant is "run like a symphony," he said. Labor costs are a small part of total production, Beaham said, with the plant employing about 60 people to produce millions of cans of starch a year. He wouldn't specify how many cans, for competitive reasons. Employees in the plant operate a highly automated system that turns raw cornstarch into refined ironing starch, which is then injected into pressurized aerosol cans. Beaham said he has had to tweak his production a little to keep pace with Wal-Mart. The largely automated line that makes cans of spray starch is the same one the company installed in 1960. More surprisingly, the production line used to make powdered starch is the same one the company installed in the late 1890 s. The burnished red steel of that line certainly has an antique look to it, but it's efficient enough to keep pace with the declining demand for powdered starch, which is much more time-consuming to use. Beaham conceded that selling to Wal-Mart has pushed his profit margins lower. The company - and the consumer market in general - demands that prices remain steady or decrease year by year, he said. Meanwhile, overhead cests tike-labor, rent and raw materials continue to cise. To keep profitable, Faultiess and Wal-Mart use a common tool: information. RETAIL LINK For the hetter part of every Monday, Benjamin Stark, vice president of marketing administration and advertising for Faultless, sits in front of his computer and peruses one of the world's biggest databases: WalMart's Retail Link. The database tracks and records every purchase made at every Wal-Mart for the last two years, said Linda Dillman, executive vice president at WalMart and the company's chief information officer. Dillman said all of the information is stored in two secret locations that hold 290 terabytes of data. That equals roughly 145 billion typed pages of text. Suppliers who sell to WalMart can gain access to the database from remote locations, she said, so they can track the sales of their own products across the nation. About 20,000 suppliers use the database, Dillman said, sending about 80,000 queries into the system daily. Retail Link lets Wal-Mart share some of the massive task of tracking merchandise and keeping store shelves stocked, Dillman said. "We replenish most of the products ourselves, but we con- sider it everyone's responsibility in the chain," she said, noting that outside suppliers are included. Shifting some of the replenishment work to suppliers was not popular at first, Glass said. Retail Link "was sort of forced on retailers," he said. But "it was one of the best things we have done for them." In the case of Faultless, Retail Link changed the business fundamentally. When Faultless firs began to use the system, it w3s the first time the company had access to its own sales infor wation in such detail. Neaham said he noticed a remarkable pattern. Sales of sprayon starch were notably higher along the Mexican border. Based on that data, the company eventually launched a line of sprayon starch in Mexico for the first time, he said. Because "Faultless" didn't translate neatly into Spanish, the company called its new line "Impecable," which has the same meaning, though slightly different spellings, in both languages. Using Retail Link can be challenging. Stark said he meets periodically with managers from other companies in Kansas City who also use the system. This "Retail Link User's Group" is a sort of social club, with members trading tips on how best to use the complicated system. Dillman said Retail Link is an example of the way Wal-Mart challenges its suppliers, while simultaneously giving them the tools to meet the demand. Stark said Wal-Mart is the only company that provides a system as sophisticated as Retail Link. "It's not just Wal-Mart" driving the changes in the consumer product industry, Stark said. "But they are at the forefront of the change," he said. 8. Think about the "perfect order" and discuss how Bon Ami's delivery times to Wal-Mart have had to become more precise. How do more precise delivery times support WalMart's low-cost/fast-growth business strategy? 9. What has been the result of Wal-Mart's supply chain approach on the long-run success of Wal-Mart and Bon Ami

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started