Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Solve step by step clearly and type otherwise I'll dislike Solve step by step clearly and type otherwise I'll dislike Guardian is a national manufacturing

Solve step by step clearly and type otherwise I'll dislike

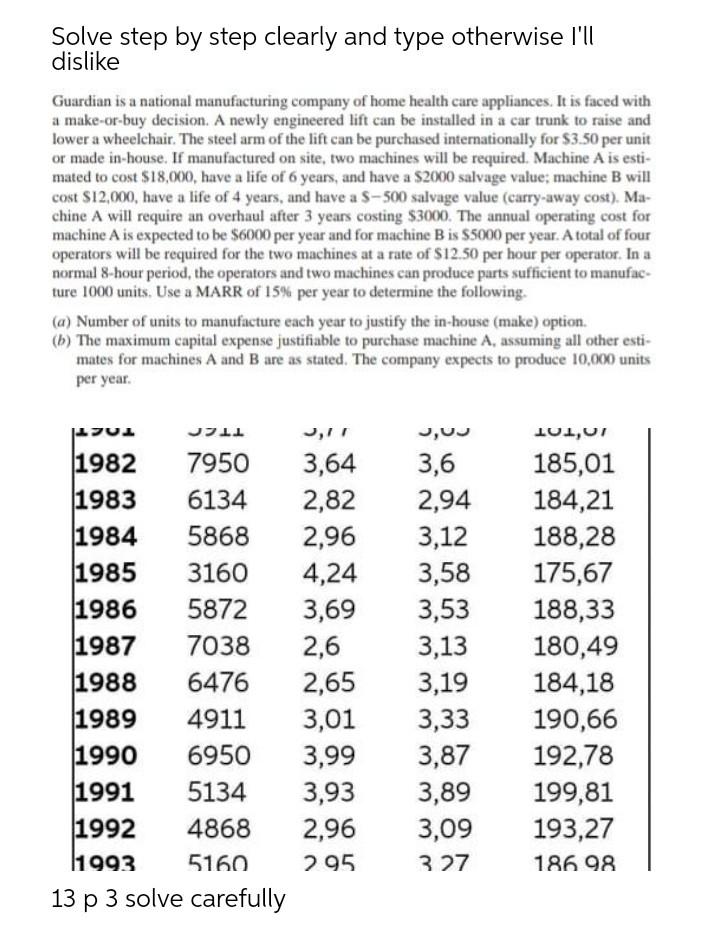

Solve step by step clearly and type otherwise I'll dislike Guardian is a national manufacturing company of home health care appliances. It is faced with a make-or-buy decision. A newly engineered lift can be installed in a car trunk to raise and lower a wheelchair. The steel arm of the lift can be purchased internationally for $3.50 per unit or made in-house. If manufactured on site, two machines will be required. Machine A is esti- mated to cost $18,000, have a life of 6 years, and have a S2000 salvage value; machine B will cost $12,000, have a life of 4 years, and have a S-500 salvage value (carry-away cost). Ma- chine A will require an overhaul after 3 years costing $3000. The annual operating cost for machine A is expected to be $6000 per year and for machine B is S5000 per year. A total of four operators will be required for the two machines at a rate of $12.50 per hour per operator. In a normal 8-hour period, the operators and two machines can produce parts sufficient to manufac ture 1000 units. Use a MARR of 15% per year to determine the following. (a) Number of units to manufacture each year to justify the in-house (make) option. (b) The maximum capital expense justifiable to purchase machine A, assuming all other esti- mates for machines A and B are as stated. The company expects to produce 10,000 units per year. JULI 1982 7950 3,64 1983 6134 2,82 1984 5868 2,96 1985 3160 4,24 1986 5872 3,69 1987 7038 2,6 1988 6476 2,65 1989 4911 3,01 1990 6950 3,99 1991 5134 3,93 1992 4868 2,96 11993 5160 295 13 p 3 solve carefully 3,03 3,6 2,94 3,12 3,58 3,53 3,13 3,19 3,33 3,87 3,89 3,09 327 101,01 185,01 184,21 188,28 175,67 188,33 180,49 184,18 190,66 192,78 199,81 193,27 186 98 Solve step by step clearly and type otherwise I'll dislike Guardian is a national manufacturing company of home health care appliances. It is faced with a make-or-buy decision. A newly engineered lift can be installed in a car trunk to raise and lower a wheelchair. The steel arm of the lift can be purchased internationally for $3.50 per unit or made in-house. If manufactured on site, two machines will be required. Machine A is esti- mated to cost $18,000, have a life of 6 years, and have a S2000 salvage value; machine B will cost $12,000, have a life of 4 years, and have a S-500 salvage value (carry-away cost). Ma- chine A will require an overhaul after 3 years costing $3000. The annual operating cost for machine A is expected to be $6000 per year and for machine B is S5000 per year. A total of four operators will be required for the two machines at a rate of $12.50 per hour per operator. In a normal 8-hour period, the operators and two machines can produce parts sufficient to manufac ture 1000 units. Use a MARR of 15% per year to determine the following. (a) Number of units to manufacture each year to justify the in-house (make) option. (b) The maximum capital expense justifiable to purchase machine A, assuming all other esti- mates for machines A and B are as stated. The company expects to produce 10,000 units per year. JULI 1982 7950 3,64 1983 6134 2,82 1984 5868 2,96 1985 3160 4,24 1986 5872 3,69 1987 7038 2,6 1988 6476 2,65 1989 4911 3,01 1990 6950 3,99 1991 5134 3,93 1992 4868 2,96 11993 5160 295 13 p 3 solve carefully 3,03 3,6 2,94 3,12 3,58 3,53 3,13 3,19 3,33 3,87 3,89 3,09 327 101,01 185,01 184,21 188,28 175,67 188,33 180,49 184,18 190,66 192,78 199,81 193,27 186 98

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started