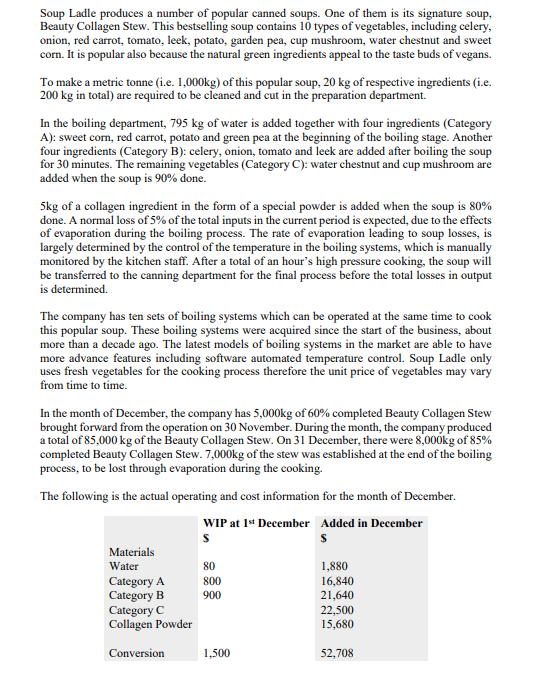

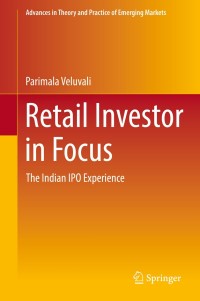

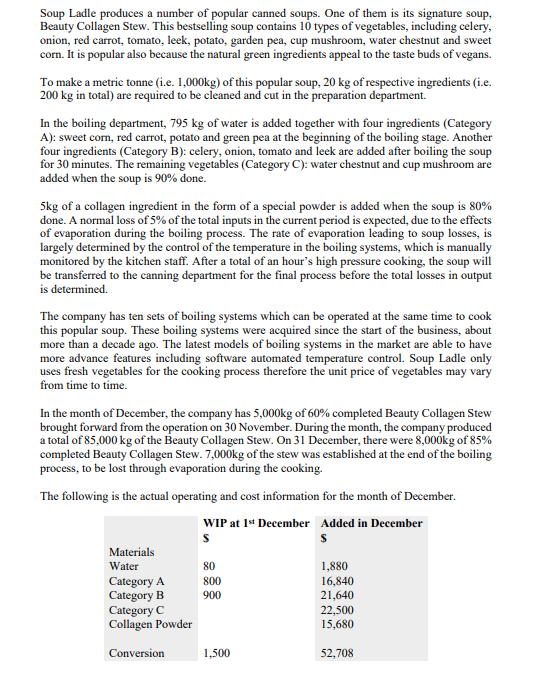

Soup Ladle produces a number of popular canned soups. One of them is its signature soup, Beauty Collagen Stew. This bestselling soup contains 10 types of vegetables, including celery, onion, red carrot, tomato, leek, potato, garden pea, cup mushroom, water chestnut and sweet corn. It is popular also because the natural green ingredients appeal to the taste buds of vegans. To make a metric tonne (i.e. 1,000kg) of this popular soup, 20 kg of respective ingredients (i.e. 200 kg in total) are required to be cleaned and cut in the preparation department. In the boiling department, 795 kg of water is added together with four ingredients (Category A): sweet corn, red carrot, potato and green pea at the beginning of the boiling stage. Another four ingredients Category B): celery, onion, tomato and leek are added after boiling the soup for 30 minutes. The remaining vegetables (Category C): water chestnut and cup mushroom are added when the soup is 90% done. 5kg of a collagen ingredient in the form of a special powder is added when the soup is 80% done. A normal loss of 5% of the total inputs in the current period is expected, due to the effects of evaporation during the boiling process. The rate of evaporation leading to soup losses, is largely determined by the control of the temperature in the boiling systems, which is manually monitored by the kitchen staff. After a total of an hour's high pressure cooking, the soup will be transferred to the canning department for the final process before the total losses in output is determined. The company has ten sets of boiling systems which can be operated at the same time to cook this popular soup. These boiling systems were acquired since the start of the business, about more than a decade ago. The latest models of boiling systems in the market are able to have more advance features including software automated temperature control. Soup Ladle only uses fresh vegetables for the cooking process therefore the unit price of vegetables may vary from time to time. In the month of December, the company has 5,000kg of 60% completed Beauty Collagen Stew brought forward from the operation on 30 November. During the month, the company produced a total of 85,000 kg of the Beauty Collagen Stew. On 31 December, there were 8,000kg of 85% completed Beauty Collagen Stew. 7,000kg of the stew was established at the end of the boiling process, to be lost through evaporation during the cooking, The following is the actual operating and cost information for the month of December. WIP at 1* December Added in December $ S Materials Water 80 1,880 Category A 800 16,840 Category B 900 21,640 Category C 22,500 Collagen Powder 15,680 Conversion 1,500 52,708 Kitchen staff are paid fixed monthly salaries. The only additional bonus that is paid at the end of the year is based on the sales of the canned soups. Due to the high popularity of Beauty Collagen Stew in the consumer market, kitchen staff had been enjoying fat bonuses ever since this product was launched. Although sales results have been impressive, profits on the other hand had been showing a declining trend. In recent months, the level of spoilage appears to be climbing up steadily. To mitigate the adverse effects of this unfavourable trend, management is considering a performance indicator being implemented on kitchen staff. The target of this performance indicator is to maintain the spoilage at its normal level. The COVID-19 pandemic has also posted significant challenges for supply chains globally. Multiple national lockdowns continue to slow or even temporarily stop the flow of supply of fresh vegetables import. As a result, prices of vegetables have become unstable and inclined towards sharp increases. The purchasing manager had been made to answer for the additional spending on ingredients due to unforeseen price increases in the global market. The purchasing manager is frustrated that he is going to lose the year-end bonus as his rewards are tied to how well the price of materials are controlled. To avoid the unstable prices, the purchasing manager is considering a partial replacement of the natural ingredients with artificially flavoured soup stock. To further reduce the cost of materials, the purchasing manager also propose to replace the special collagen Powder with a cheaper source of gelatin ingredient that has a similar texture to genuine collagen. The purchasing manager strongly believes that profits will improve if these replacements on materials can be implemented. You are an intern engaged by Soup Ladle to understudy the company's current issues and analyse how the application of organisational architecture may help to improve overall performance. Required: (a) Use process costing to prepare a production cost report for Beauty Collagen Stew for December using the FIFO method. Your report should show the following: (i) Equivalent units computed for production with regards to each cost category (nearest 5 decimal places). (ii) Costs of normal spoilage and abnormal spoilage (show a separate computation of how normal spoilage in kg is derived). (iii) Cost of units transferred out of Boiling Process. (iv) Cost of Ending WIP. Soup Ladle produces a number of popular canned soups. One of them is its signature soup, Beauty Collagen Stew. This bestselling soup contains 10 types of vegetables, including celery, onion, red carrot, tomato, leek, potato, garden pea, cup mushroom, water chestnut and sweet corn. It is popular also because the natural green ingredients appeal to the taste buds of vegans. To make a metric tonne (i.e. 1,000kg) of this popular soup, 20 kg of respective ingredients (i.e. 200 kg in total) are required to be cleaned and cut in the preparation department. In the boiling department, 795 kg of water is added together with four ingredients (Category A): sweet corn, red carrot, potato and green pea at the beginning of the boiling stage. Another four ingredients Category B): celery, onion, tomato and leek are added after boiling the soup for 30 minutes. The remaining vegetables (Category C): water chestnut and cup mushroom are added when the soup is 90% done. 5kg of a collagen ingredient in the form of a special powder is added when the soup is 80% done. A normal loss of 5% of the total inputs in the current period is expected, due to the effects of evaporation during the boiling process. The rate of evaporation leading to soup losses, is largely determined by the control of the temperature in the boiling systems, which is manually monitored by the kitchen staff. After a total of an hour's high pressure cooking, the soup will be transferred to the canning department for the final process before the total losses in output is determined. The company has ten sets of boiling systems which can be operated at the same time to cook this popular soup. These boiling systems were acquired since the start of the business, about more than a decade ago. The latest models of boiling systems in the market are able to have more advance features including software automated temperature control. Soup Ladle only uses fresh vegetables for the cooking process therefore the unit price of vegetables may vary from time to time. In the month of December, the company has 5,000kg of 60% completed Beauty Collagen Stew brought forward from the operation on 30 November. During the month, the company produced a total of 85,000 kg of the Beauty Collagen Stew. On 31 December, there were 8,000kg of 85% completed Beauty Collagen Stew. 7,000kg of the stew was established at the end of the boiling process, to be lost through evaporation during the cooking, The following is the actual operating and cost information for the month of December. WIP at 1* December Added in December $ S Materials Water 80 1,880 Category A 800 16,840 Category B 900 21,640 Category C 22,500 Collagen Powder 15,680 Conversion 1,500 52,708 Kitchen staff are paid fixed monthly salaries. The only additional bonus that is paid at the end of the year is based on the sales of the canned soups. Due to the high popularity of Beauty Collagen Stew in the consumer market, kitchen staff had been enjoying fat bonuses ever since this product was launched. Although sales results have been impressive, profits on the other hand had been showing a declining trend. In recent months, the level of spoilage appears to be climbing up steadily. To mitigate the adverse effects of this unfavourable trend, management is considering a performance indicator being implemented on kitchen staff. The target of this performance indicator is to maintain the spoilage at its normal level. The COVID-19 pandemic has also posted significant challenges for supply chains globally. Multiple national lockdowns continue to slow or even temporarily stop the flow of supply of fresh vegetables import. As a result, prices of vegetables have become unstable and inclined towards sharp increases. The purchasing manager had been made to answer for the additional spending on ingredients due to unforeseen price increases in the global market. The purchasing manager is frustrated that he is going to lose the year-end bonus as his rewards are tied to how well the price of materials are controlled. To avoid the unstable prices, the purchasing manager is considering a partial replacement of the natural ingredients with artificially flavoured soup stock. To further reduce the cost of materials, the purchasing manager also propose to replace the special collagen Powder with a cheaper source of gelatin ingredient that has a similar texture to genuine collagen. The purchasing manager strongly believes that profits will improve if these replacements on materials can be implemented. You are an intern engaged by Soup Ladle to understudy the company's current issues and analyse how the application of organisational architecture may help to improve overall performance. Required: (a) Use process costing to prepare a production cost report for Beauty Collagen Stew for December using the FIFO method. Your report should show the following: (i) Equivalent units computed for production with regards to each cost category (nearest 5 decimal places). (ii) Costs of normal spoilage and abnormal spoilage (show a separate computation of how normal spoilage in kg is derived). (iii) Cost of units transferred out of Boiling Process. (iv) Cost of Ending WIP