Question

Southern Manufacturing Company manufactures dashboard instruments for passenger and commercial vehicles. The firm operates several divisions in China, each of which operates independently as a

Southern Manufacturing Company manufactures dashboard instruments for passenger and commercial vehicles. The firm operates several divisions in China, each of which operates independently as a profit center. The Shenzhen Division manufactures two types of electrical components used in the production of the firm's dashboard instruments. The basic component (BC) is used in less-complicated instruments while the multi-functional component (MC) is

used in the most sophisticated instruments.

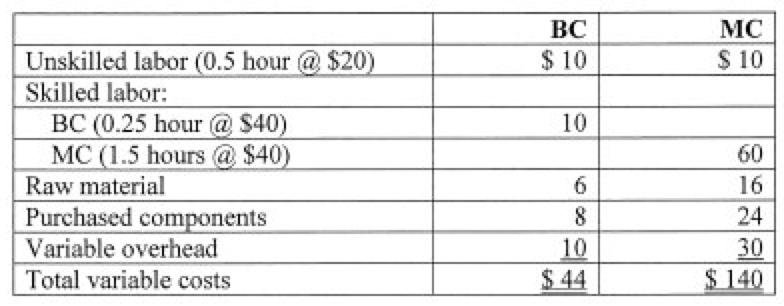

The product costs for each unit of BC and MC is provided in the following table:

The annual fixed overhead in the Shenzhen Division is $2,000,000 and is allocated to the two products using number of skilled labor hours. Due to the tight skilled labour market, the available skilled labour for the Shenzhen division is 40,000 hours each year. BC is doing very well, selling for $56 per unit with excess demand. The demand for MC has

increased in recent years, and the division could sell up to 6,000 units per year at a price of

$230 per unit.

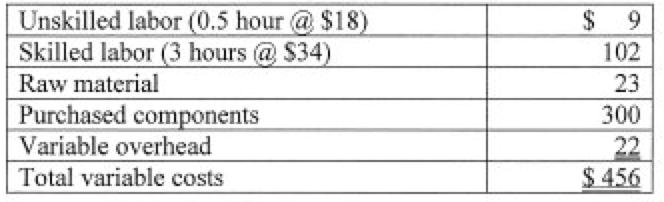

As the business grows, Southern Manufacturing Company has expanded its product portfolio and started a new division in Beijing, which produces a sophisticated instrument used in hybrid and electric vehicles. This instrument, designated as HEV, has the following product cost per unit:

The cost of purchased components for the HEV includes a $290 control pack currently imported from Germany. A research project conducted by the Beijing Division has revealed that Shenzhen Division's MC can be a viable substitute for the control pack.

If the division replaces the imported control pack with the MC, the $290 control pack cost can be avoided. In addition, the Beijing Division will save $11 on raw materials. However, in order to use the MC unit in the HEV, the Beijing Division will need an additional two hours of skilled labor to make the necessary modifications. The cost of transporting the MC to Beijing is $9 per unit, which will be borne by the Beijing Division. There are no other changes to costs. The Beijing Division can use up to 10,000 of the MC per year based on the expected sales of HEV.

Required

(a) Assuming that no transfers of MCs are made to the Beijing Division, how many BCs and MCs should the Shenzhen Division sell to maximize its divisional profit? What is the maximum profit that the division can achieve in a year? Show your workings.

(b) The Shenzhen and Beijing divisions are evaluating the internal transfer of MC. What is the acceptable range, if any, for the transfer price of MC between the two divisions? Show your workings. Is the transfer likely to take place?

(c) Evaluate the decision of using MC in producing HEV units from the perspective of the company.

(i) Should any of the HEV units be produced using MC? If so, how many? Show your workings.

(ii) Discuss two strategic factors that the company should consider when making this decision.

(d) Like many other companies in the industry, Southern Manufacturing Company has developed a corporate sustainability program. Briefly explain the framework of "triple bottom line" and describe how the company can incorporate sustainability into its Balanced Scorecard.

MC $ 10 $ 10 Unskilled labor (0.5 hour @$20) Skilled labor: BC (0.25 hour @ $40) MC (1.5 hours @ $40) Raw material Purchased components Variable overhead Total variable costs 10 60 6. 16 8 24 10 $ 44 30 $ 140

Step by Step Solution

3.44 Rating (160 Votes )

There are 3 Steps involved in it

Step: 1

ANSWERS a The Shenzhen Division should sell 44 BCs and 140 MCs to maximize its divisional profit The maximum profit that the division can achieve in a year is 22800 b The acceptable range for the tran...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started