Question

A machining company produces one of the tools for any assembly lines. One of the most important quality dimensions is the diameter of a screws

A machining company produces one of the tools for any assembly lines. One of the most important quality dimensions is the diameter of a screws installed into the assemblies. The management has a record of the process average diameter at 0.15 inch. Historically, the standard deviation has been 0.02 inch, regardless of the process average. Management provided the results of 80 minutes of output from the production line, as shown in the table below, and decided to take a sample size of 4. The frequency should be sample four then skip four. Thus, your first sample would be for minutes 1-4, the second would be for minutes 9-12, and so on. The management would like to know if the process is shifted away from the historical average. Based on the control charts you construct, what is your opinion?

Minutes - Diameter

1-12: 0.15 0.16 0.18 0.14 0.16 0.17 0.15 0.14 0.14 0.13 0.16 0.17

13-24: 0.15 0.16 0.17 0.16 0.14 0.14 0.13 0.14 0.15 0.16 0.15 0.17

25-36: 0.14 0.13 0.15 0.17 0.18 0.15 0.16 0.15 0.14 0.15 0.16 0.17

37-48: 0.18 0.16 0.15 0.16 0.16 0.14 0.17 0.18 0.19 0.15 0.16 0.15

49-60: 0.12 0.17 0.16 0.14 0.15 0.17 0.14 0.16 0.15 0.17 0.18 0.14

61-72: 0.15 0.16 0.17 0.18 0.13 0.15 0.14 0.14 0.16 0.15 0.17 0.18

73-80: 0.16 0.16 0.17 0.18 0.16 0.15 0.14 0.17

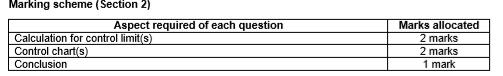

Marking scheme (Section 2) Aspect required of each question Marks allocated Calculation for control limit(s) Control chart(s) Conclusion 2 marks 2 marks 1 mark

Step by Step Solution

3.52 Rating (152 Votes )

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started