Answered step by step

Verified Expert Solution

Question

1 Approved Answer

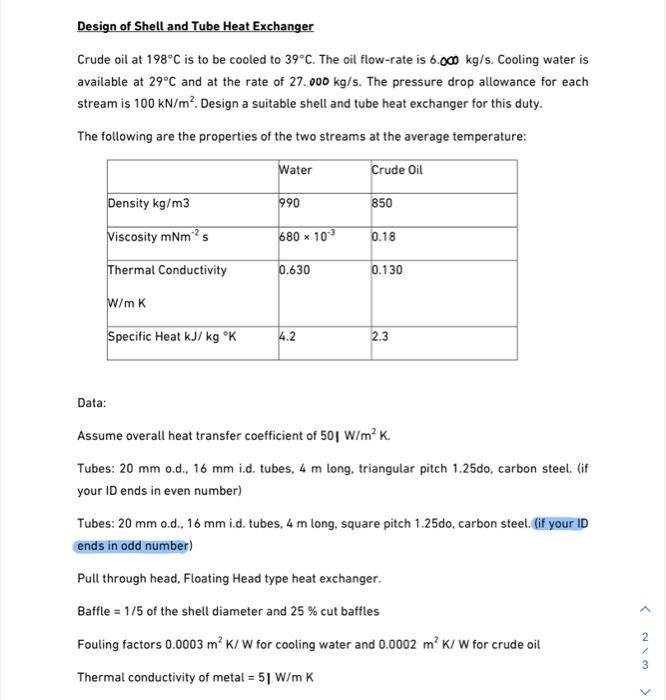

step by step Design of Shell and Tube Heat Exchanger Crude oil at 198C is to be cooled to 39C. The oil flow-rate is 6.000kg/s.

step by step

Design of Shell and Tube Heat Exchanger Crude oil at 198C is to be cooled to 39C. The oil flow-rate is 6.000kg/s. Cooling water is available at 29C and at the rate of 27.000kg/s. The pressure drop allowance for each stream is 100kN/m2. Design a suitable shell and tube heat exchanger for this duty. The following are the properties of the two streams at the average temperature: Data: Assume overall heat transfer coefficient of 50WW/m2K Tubes: 20mm o.d., 16mm i.d. tubes, 4m long. triangular pitch 1.25do, carbon steel. (if your ID ends in even number) Tubes: 20mm o.d., 16mm i.d. tubes, 4m long, square pitch 1.25do, carbon steel. (if your ID ends in odd number) Pull through head, Floating Head type heat exchanger. Baffle =1/5 of the shell diameter and 25% cut baffles Fouling factors 0.0003m2K/W for cooling water and 0.0002m2K/W for crude oil Thermal conductivity of metal =51W/mK

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started