Question

Summarize the case in 1 paragraph and answer the questions in 3 to 4 pages. Questions: 1. Apollo serves 120 food items from its kitchen.

Summarize the case in 1 paragraph and answer the questions in 3 to 4 pages.

Questions:

1. Apollo serves 120 food items from its kitchen. Do you think that Apollo should develop forecasting models for all 120 items?

2. Explore the data provided in the supplement document. What inferences can be obtained from the data?

3. Develop an appropriate forecasting model for each of the chosen food items. Discuss the results of the models developed and their appropriateness for use.

4. Dr. Rao has suggested that the food demand is related to occupancy. Is there statistical evidence for this belief?

5. What will be your recommendation on the use of daily occupancy in the forecasting model?

6. Suggest suitable action for Apollo hospitals going forward for a proper estimation of food demand.

Explain the significant problem, and propose and defend your solutions to the problem.

Please consider the below points while responding to the case and questions:

* Summary/Introduction : (Includes relevant internal/external facts and background)

* Responses to questions: (Accurately answers all the questions given for the case)

* Problem Definition and Issues: (Clarity in specifying the problem(s) facing the management team)

* Critical analysis and solution: (Clearly analyzes each alternative and identifies the best alternative, and the rationale for that decision)

Please respond in detail, with a proper explanation and based on all the requirements mentioned in the case.

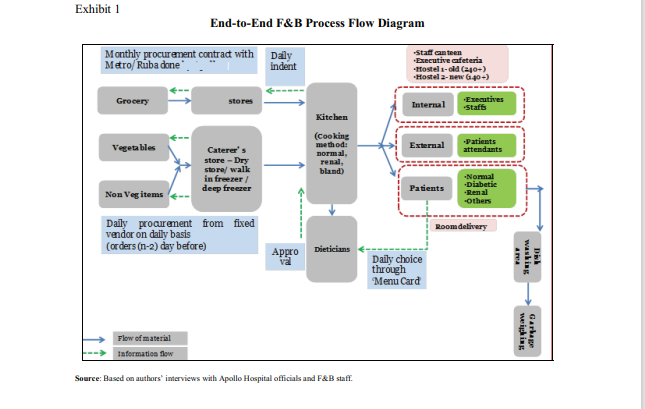

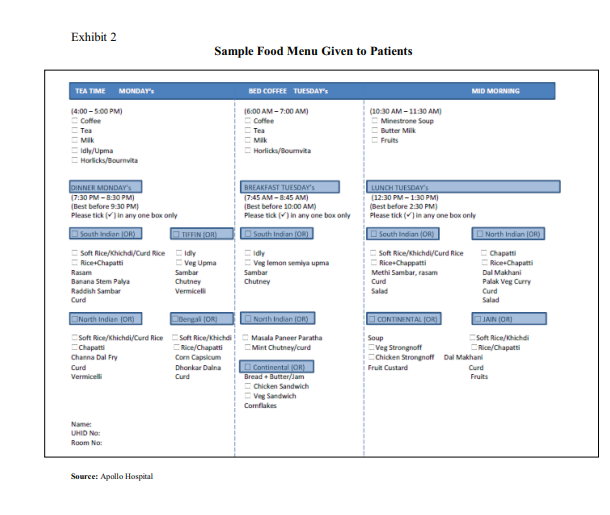

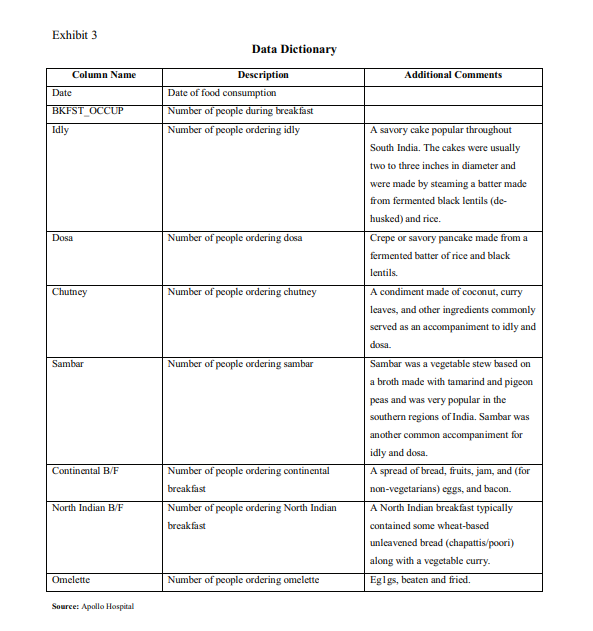

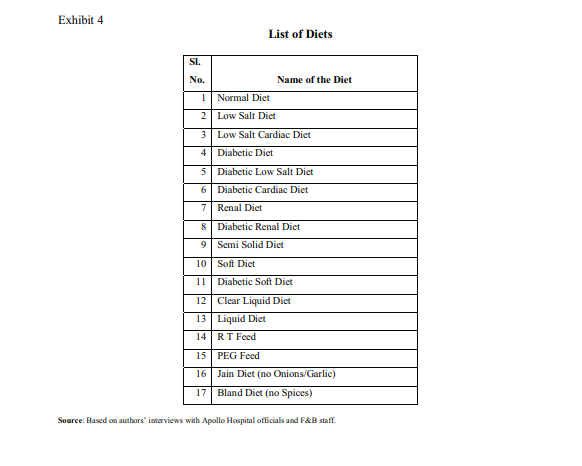

FORECASTING DEMAND FOR FOOD AT APOLLO HOSPITALS It was almost 6 o'clock in the evening, but Dr. Ananth N. Rao was still struggling to figure out the amount of food that was being consumed by the in-patients at Apollo Hospital, Bannerghatta Road, Bangalore from the monthly bills of food items. He wondered how he could accurately estimate the required quantity of food and beverage items so as to reduce the overall wastage in food and beverages, which constituted about 4% of the overall costs of the hospital. Discussions with the Finance Team indicated a non-specific trend of expenditures versus revenue. He proceeded to discuss with the CEO, Dr. Umapathy Panyala about possible solutions. The CEO, himself an expert in Operations and Costing suggested several models to address the issue. On the next moming, Dr. Rao made enquiries with Deepak, Head of the Food and Beverages (F\&B) division. Dr. Rao found that on a daily basis, they had been preparing food items that were more than 20% in excess of the quantity that was estimated based on previous experience. There had been days when the wastage was more than 50-60\%. For instance, Dr. Rao noticed that 45 plates/servings of rice were left over after dinner service one day; the consumption of rice for dinner that same day was approximately 75 plates/portions. Being a Six Sigma black belt and practitioner of lean management, Dr. Rao realized that this did not augur well with the operating plan of the organization. He knew that the estimation of the hospital's food and beverages (F\&B) requirements based on an ad hoc method would not be sufficient to rectify the problem. Food was prepared for around 230 in-patients daily for breakfast, lunch, and dinner. The in-patients ordered food from the menu given to them every day. Food orders for breakfast were taken the day before and those for lunch and dinner were taken in the morning. The F\&B staff also had to account for the F\&B requirements of outpatients, caregivers/attendants, and visitors of the in-patients and the hospital staff. Since it would not be possible to accurately predict such requirements, the F\&B staff used to rely on past experiences to estimate the quantity of food items that needed to be prepared. According to the orders from all the in-patients and based on the experience of the F\&B staff (especially the head chef), the final quantity of food was decided and prepared. Normally, 10% excess food was prepared to avoid any shortage. Based on the consumption of food in the kitchen, raw material - broadly defined as "grocery items", which included vegetables, meat, milk, liquids, and other items - was procured. Hence, preparation of excess food not only resulted in wastage of food but also led to extra expenditure in purchasing raw material. Dr. Rao walked across the road to the Indian Institute of Management Bangalore, situated opposite Apollo Hospital, to discuss the problem with his friend, Professor Dinesh Kumar. After listening to Dr. Rao, the professor promised to send two of his students, Sujoy and Alok, to study the matter in detail and come up with a solution. After the discussion with the professor, Dr. Rao appeared to be a bit relieved. However, there were several questions still on his mind.Could he establish a system that could accurately estimate the required quantity of food and beverages? If the system were to be successful, could it be applied to the other Apollo Hospital branches? Another worrying point was that the number of beds in the hospital was likely to increase in the future. Even if a forecasting model were to be developed based on the past data, what would be the limitations of the model? APOLLO HOSPITALS Dr. Prathap C. Reddy hailed from a village in Andhra Pradesh (a southem state in India). He received his premedical degree from the prestigious Madras Christian College and his medical degree from Stanley Medical College, both in Chennai, India. He did his fellowship at the Massachusetts General Hospital, Boston, U.S.A. and went on to head the research programs at the Missouri State Chest Hospital. When Dr. Reddy returned to India in 1978 at the behest of his father, he was indeed taking the road less traveled. To give up a flourishing practice abroad and retum to India was looked upon as foolhardy in those days. Just as he was settling down, something happened that not only shook his world, but changed it forever. In 1979, one of his young patients succumbed to coronary heart disease owing to the lack of advanced health care in the country and its prohibitive cost overseas. Dr. Reddy realized that such tragedieswere commonplace in the country and would continue to be so until someone did something about it. At the age of 50 years, Dr. Reddy decided to establish Apollo Hospitals. The first Apollo Hospital came up in Chennai in 1983. As of 2014, the Apollo Hospitals Group was an integrated healtheare organization with owned and managed hospitals, diagnostic clinics, dispensing pharmacies, and consultancy services. In addition, the group's service offerings included health care at the patient's doorstep, clinical and diagnostic services, medical business process outsourcing, third-party administration services, and health insurance. To cnhance performance and service to its customers, the group also made available services to support business, telemedicine services, education, training programs, and research services, and a host of other non-profit projects. 1 Starting in 1983, Apollo had now grown to over 8,300 beds across 51 hospitals. 2 The Apollo Hospital Bangalore at Bannerghatta Road was a tertiary care hospital. It was a 250-bed hospital, beautifully landscaped and spread over an area of 2,12,000sq. ft. The hospital was equipped with state-of-the-art technology. It was certified by the Joint Commission International (JCI). 3 On average, 230 in-patients were treated at the hospital daily. Food and beverages were served to these patients as per their choice and/or based on the recommendations of their doctors and the hospital's dieticians. The quantity of food and beverages that was prepared daily was based on the rough estimates of the head chef. END-TO-END F\&B PROCESS FLOW The hospital had 230 in-patients on average; additionally, there were caregivers/attendants (people who stayed with the paticnt in the hospital) and staff. The hospital also had an executive canteen and two hostels for residential staff. Sujoy and Alok limited their study to the food being consumed by the in-patients. The F\&B department was managed by a third-party provider who was managed by the staff at the hospital. All the processes involving F\&B at Apollo Hospital are presented in an indicative flow diagram in Exhibit 1. The major processes are described here. Procurement process Procurement of the grocery items was done on a monthly basis from Metro or Ruba-large wholesale grocery chains in India - based on the contracts with them. The grocery items were stored in the hospital-managed store and the daily grocery requirements were indented by the cook every day. Vegetables, fruits, and non-vegetarian items were ordered 2 days in advance. They were delivered to the hospital 1 day in advance. These items were stored in various stores in the kitchen area such as the dry store, walk-in freezers, and the deep freezer. Ordering process There were three consumption centers for food at Apollo Hospital: the internal canteen for hospital executives and staff; the cafeteria for visitors; and the in-patients and their caregivers/attendants, who would be provided food in their rooms based on their ordersand/or the recommendations of their doctors and the dieticians. For the purpose of this analysis, only the food consumption of the in-patients and their caregivers/attendants was considered. The choice of food from the menu (Exhibit 2) was collected from the in-patients (henceforward, "patients") each day for lunch and dinner and the day before for breakfast; their choices had to be approved by the dietician before they were sent to the kitchen. The data was collected using paper forms (hard copies), which had to be manually consolidated at the kitchen. The food was cooked in keeping with the specific dietary requirements of various Food waste handling process The food waste was collected by the hospital staff and brought to the dish washing area, where it was weighed and then disposed off appropriately. CATEGORIZATION OF F\&B WASTAGE Based on their interviews with the F\&B staff, Sujoy and Alok categorized the food wastage at Apollo Hospital into various categories. Categorization of wastage was based on the flow of F\&B starting from procurement to consumption. Pre-consumption wastage Pre-consumption wastage happened primarily because the amount of food prepared was more than the quantity required for the number of patients on a given day. From the interview with the F&B Head, it was found that around 10% excess food was prepared based on the occupancy. Pre-consumption wastage could also happen in the process of food preparation, which was ignored in this analysis. Post-consumption wastage This wastage happened primarily because of leftovers, which could be attributed to the taste preferences of the patients, the quality of the food served, size of the serving, and various other reasons. To analyze these factors, customer feedback would be required; hence, this aspect was excluded from the scope of this analysis. Losses owing to excess procurement With the excess daily preparation of food, the estimated procurement of grocery items, vegetables/fruits, and nonvegetarian items was expected to be higher than necessary. Although no data was available to validate this, it was expected to be a source of loss. The requirement of raw material was determined based on the benchmarked quantity requirement for each menu item. DATA COLLECTION Having understood the process, the next step was to collect data. The intent was to get hold of as much historical data as possible about the daily occupancy level and item-wise order details. The issue was that the data was not readily available in the desired format, since some of the data was in paper format. For instance, the patients' choice of food was manually noted on a "Menu Card" daily. Data Description The data collected provided the details of each of the food items served during breakfast between October 1, 2012 and January 23, 2013. The occupancy was also provided during breakfast. Exhibit 3 provides the data dictionary for breakfast consumption, which was provided as an additional supplement. Exhibit 4 showed the different types of diets in the hospital. Many of the food items could be available across various diets; the volumes for these were the total across all such diets. The objective was to estimate the demand for each food item 2 days ahead as well as 1 day ahead so that procurement could be done in a proper manner. Sujoy and Alok had their work cut out for them. Even as the two bright young students left his office, Dr. Rao knew that developing the model was just the beginning. He knew that implementing significant improvements in a people-intensive process was more challenging than building the most complex forecasting models. Irrespective of all the noble intentions and the costdriven targets of reducing food wastage, he knew that he was running a hospital and not a restaurant. If he drove his procurement by statistical models and there was a shortfall one day, how would he explain the situation to his patients? They were there not to get food but to get world-class treatment and the unavailability of certain items on the menu might not be acceptable to them, especially given that they were already stressed out about more important things. What was acceptable deviation in a forecasting model could well be unacceptable to the patients. He also had to deal with issues of scalability and model maintenance. How would the model be maintained going forward? Moreover, what would he do if and when the hospital expanded? The hospital had very recently increased its size by 25% and another expansion was unlikely to take place within the next year or so; however, from a longterm perspective, this was something he had to consider. He had no idea whether he could just say that the model could be scaled upwards by a similar factor if there were to be an expansion. The other issue on hand was regarding how to roll out similar processes in various other Apollo units, if not all over India, then at least in Bangalore (there were four Apollo Hospitals in Bangalore). He knew that the composition of the patients in each of the hospitals was similar in terms of their medical records, but how similar was it demographically? Also, what changes would need to be done to roll out such processes across an organization? Was building individual models the correct procedure and was it cost effective? What would he discuss with the CEO as the next improvization? It was well past 8 pm and it was time to leave for the day, but Dr. Rao would have his plate full for many weeks to come. End-to-End F\&B Process Flow Diagram source: based on autnors' imerviews wun opoub Hospital omctass ana fas start. Sample Food Menu Given to Patients List of Diets Source: Based on authors" imterviews with Apollo Hospital officials and FAB staffStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started