Answered step by step

Verified Expert Solution

Question

1 Approved Answer

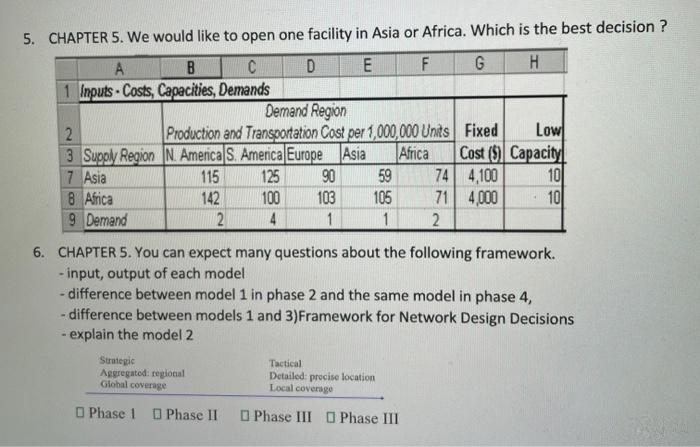

Supply chain managment These are the models 5. CHAPTER 5. We would like to open one facility in Asia or Africa. Which is the best

Supply chain managment

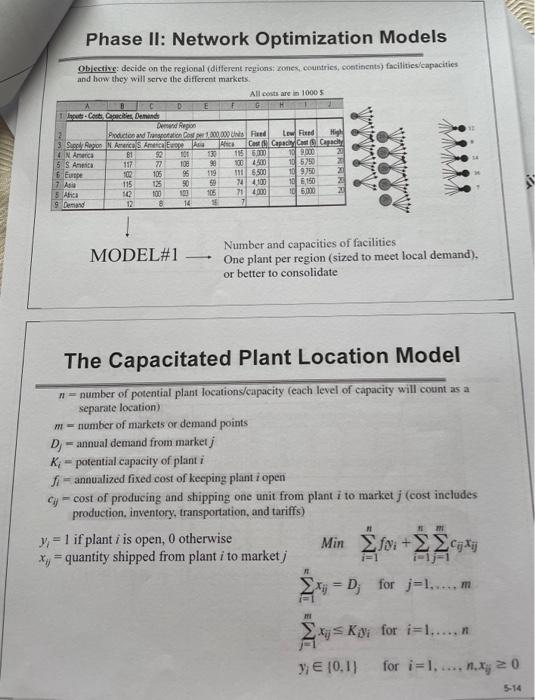

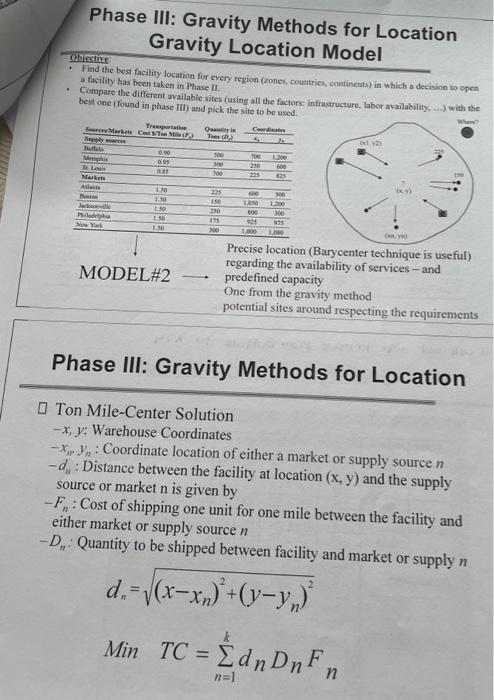

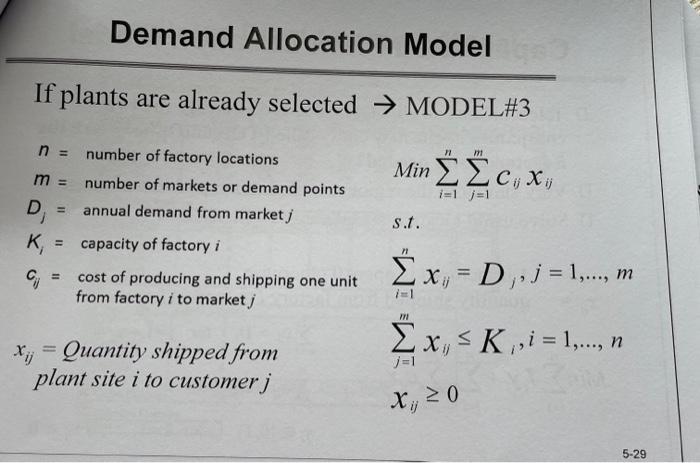

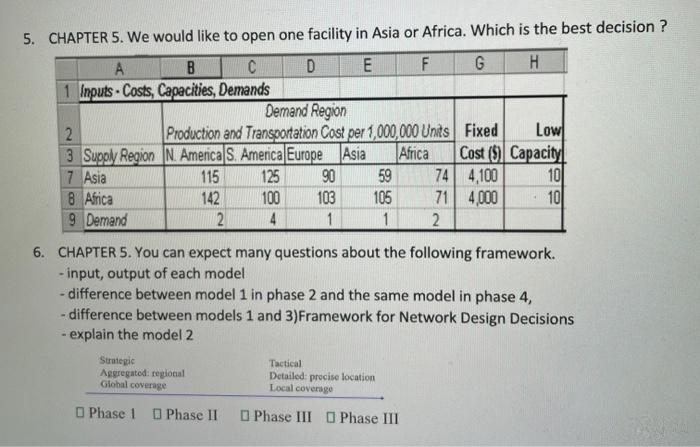

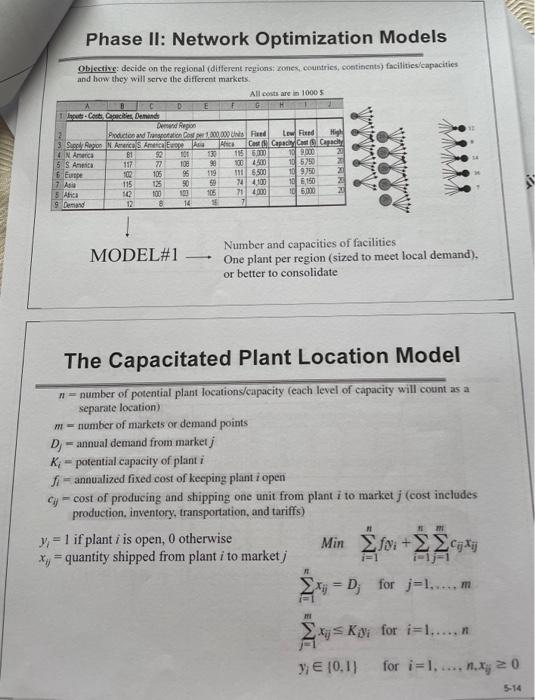

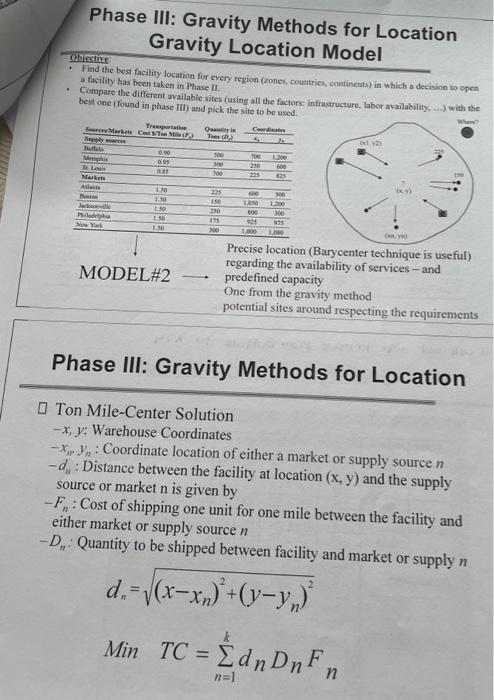

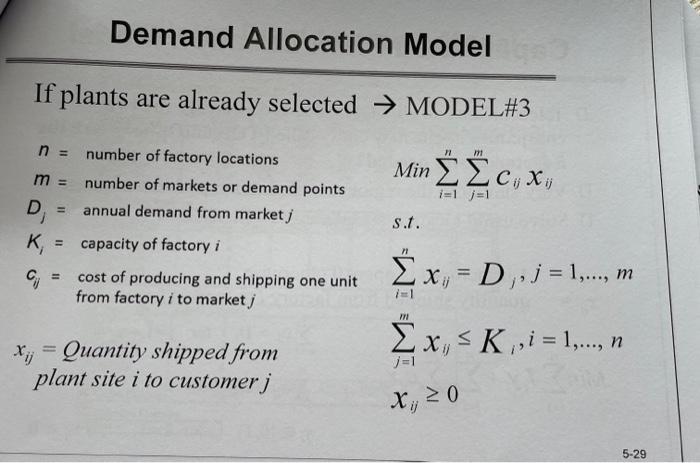

5. CHAPTER 5. We would like to open one facility in Asia or Africa. Which is the best decision ? 6. CHAPTER 5. You can expect many questions about the following framework. - input, output of each model - difference between model 1 in phase 2 and the same model in phase 4, - difference between models 1 and 3)Framework for Network Design Decisions - explain the model 2 Phase II: Network Optimization Models Obiective: decide on the regional (different regions; Zonex, countries, contincnts) facilitiesicapacities and how they will serve the different markets MODEL\#1 Number and capacities of facilities One plant per region (sized to meet local demand), or better to consolidate The Capacitated Plant Location Model n= number of potential plant locations/capacity (each level of capacity will count as a separate location) m= number of markets or demand points Dj= annual demand from market j Ki= potential capacity of plant i fi= annualized fixed cost of kecping plant i open cij=cost of producing and shipping one unit from plant i to market j (cost includes production, inventory, transportation, and tariffs) yl=1 if plant i is open, 0 otherwise xij= quantity shipped from plant i to market j Mini=1nfiyi+i=1nj=1mcijxij i=1nxij=Djforj=1,mj=1mxijKiyifori=1,,nyi{0,1}fori=1,,n,xij0 Phase III: Gravity Methods for Location Gravity Location Model onbiestive Find the best facility location for every region (nones, countries; continents) in which a decision to open a facility has been taken in Phase II best one (found in phase III) and pick the site to be used. useful) d Precise location (Barycenter technique is useful) regarding the availability of services - and predefined capacity One from the gravity method potential sites around respecting the requirements Phase III: Gravity Methods for Location Ton Mile-Center Solution x,y : Warehouse Coordinates xnyn: Coordinate location of either a market or supply source n dn : Distance between the facility at location (x,y) and the supply source or market n is given by Fn : Cost of shipping one unit for one mile between the facility and either market or supply source n Dn : Quantity to be shipped between facility and market or supply n dn=(xxn)2+(yyn)2MinTC=n=1kdnDnFn If plants are already selected MODEL\#3 n=numberoffactorylocationsm=numberofmarketsordemandpointsDj=annualdemandfrommarketjKi=capacityoffactoryicij=costofproducingandshippingoneunitfromfactoryitomarketji=1nxij=Dj,j=1,,mxij=QuantityshippedfromMini=1nj=1mcijxijs.t.plantsiteitocustomerjj=1mxijKi,i=1,,nxij0

These are the models

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started