Answered step by step

Verified Expert Solution

Question

1 Approved Answer

SURF SHAPER CASE STUDY Surf Shaper, a surf warehouse in California, serves over 300 surf shops and retailers along the California coast. Surf Shaper places

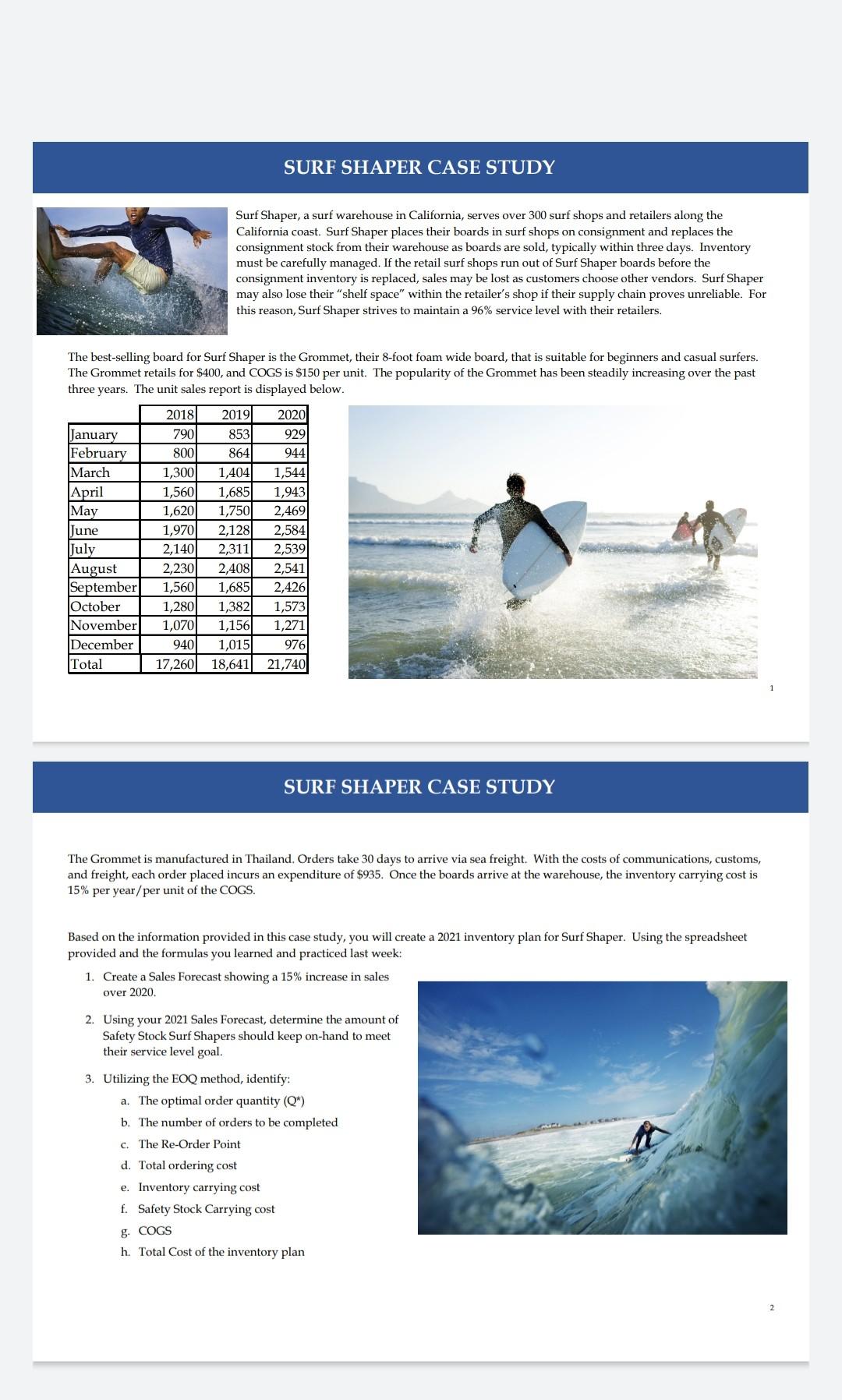

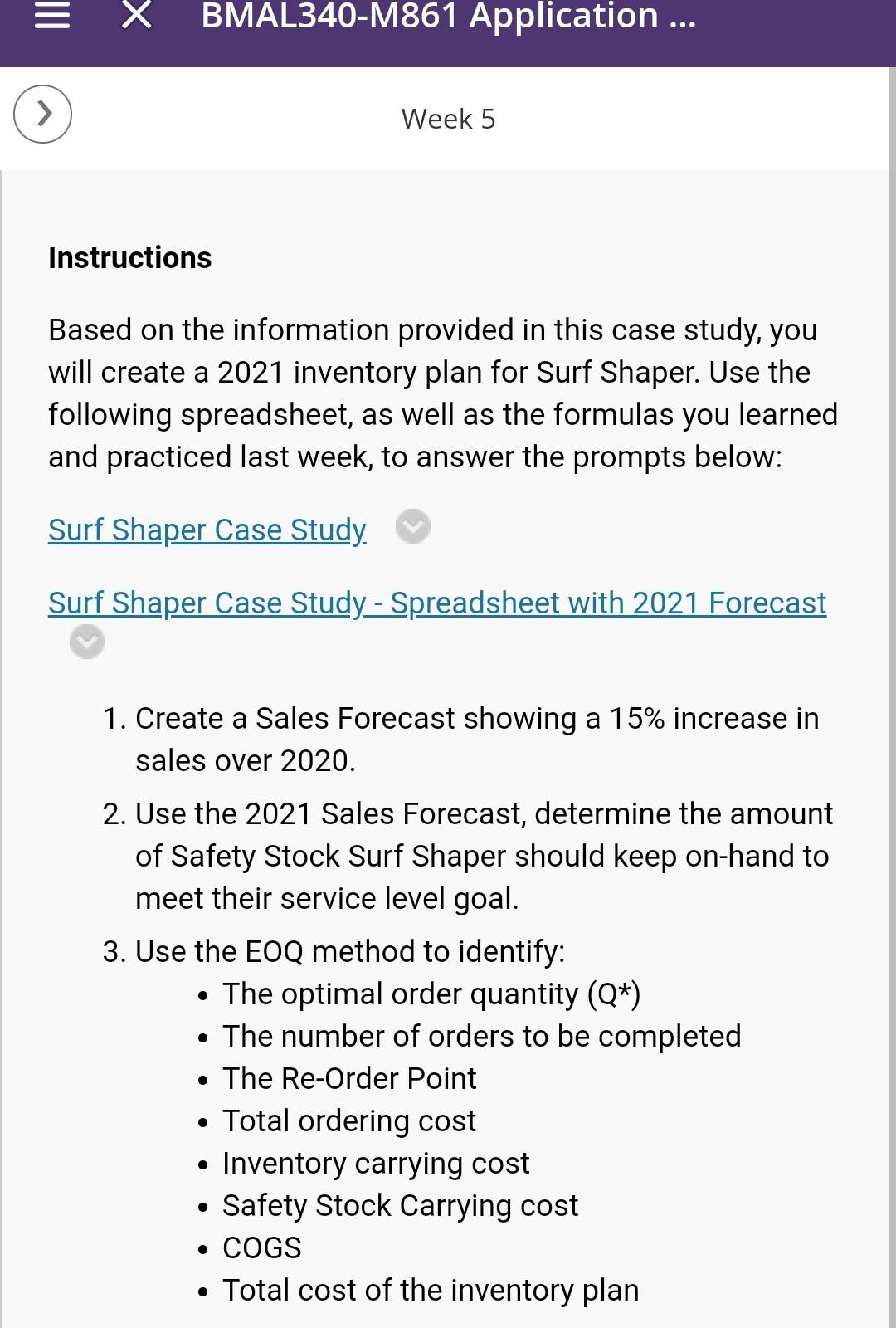

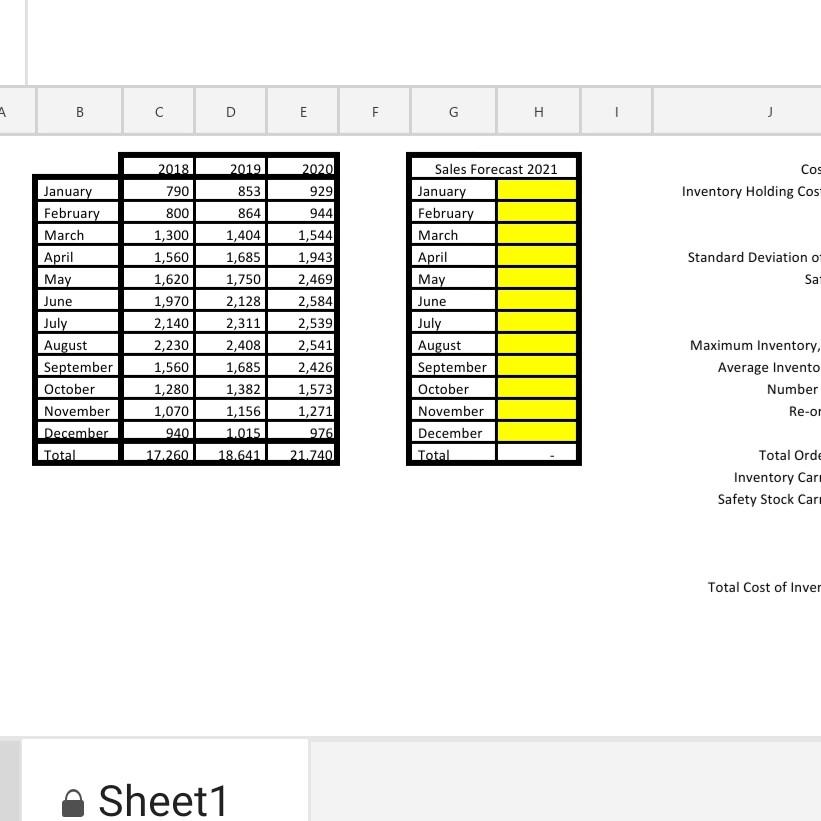

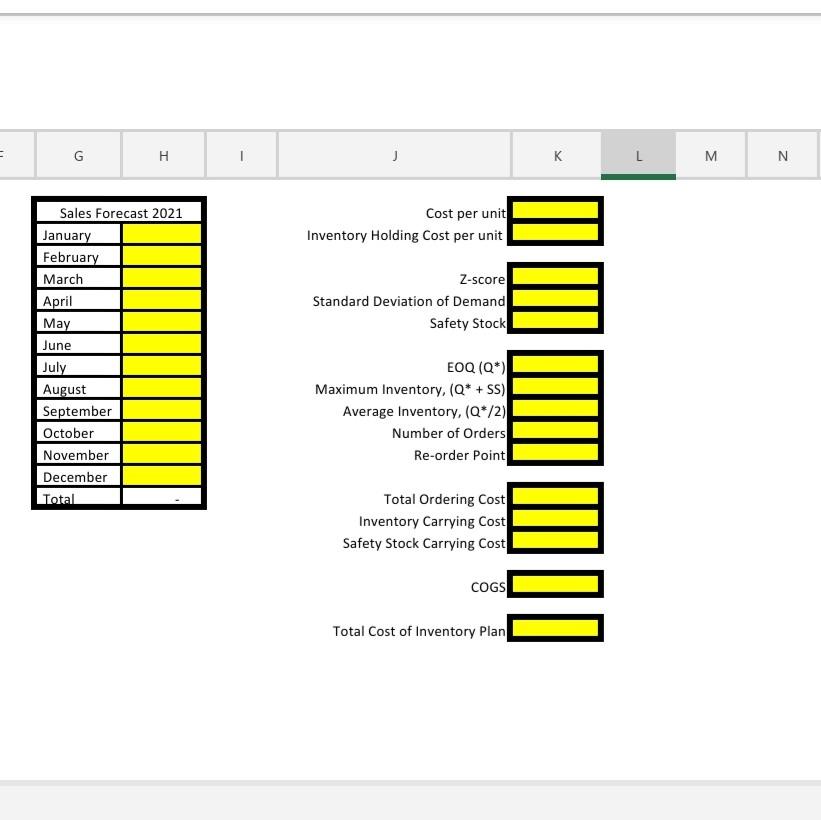

SURF SHAPER CASE STUDY Surf Shaper, a surf warehouse in California, serves over 300 surf shops and retailers along the California coast. Surf Shaper places their boards in surf shops on consignment and replaces the consignment stock from their warehouse as boards are sold, typically within three days. Inventory must be carefully managed. If the retail surf shops run out of Surf Shaper boards before the consignment inventory is replaced, sales may be lost as customers choose other vendors. Surf Shaper may also lose their "shelf space" within the retailer's shop if their supply chain proves unreliable. For this reason, Surf Shaper strives to maintain a 96% service level with their retailers. 800 The best-selling board for Surf Shaper is the Grommet, their 8-foot foam wide board, that is suitable for beginners and casual surfers. The Grommet retails for $400, and COGS is $150 per unit. The popularity of the Grommet has been steadily increasing over the past three years. The unit sales report is displayed below. 2018) 2019 2020 January 790 853 929 February 8641 944 March 1,300 1,404 1,544 April 1,560 1,685 1,943 May 1,6201 1,750 2,469 June 1,970 2,128 2,584 July 2,140 2,311 2,539 August 2,230 2,408 2,541 September 1,560 1,685 2,426 October 1,280 1,382 1,573 November 1,070 1,156) 1,271 December 940 1,015 976 Total 17,260 18,641 21,740 SURF SHAPER CASE STUDY The Grommet is manufactured in Thailand. Orders take 30 days to arrive via sea freight. With the costs of communications, customs, and freight, each order placed incurs an expenditure of $935. Once the boards arrive at the warehouse, the inventory carrying cost is 15% per year/per unit of the COGS. Based on the information provided in this case study, you will create a 2021 inventory plan for Surf Shaper. Using the spreadsheet provided and the formulas you learned and practiced last week: 1. Create a Sales Forecast showing a 15% increase in sales over 2020. 2. Using your 2021 Sales Forecast, determine the amount of Safety Stock Surf Shapers should keep on-hand to meet their service level goal. 3. Utilizing the EOQ method, identify: a. The optimal order quantity (Q*) b. The number of orders to be completed c. The Re-Order Point d. Total ordering cost e. Inventory carrying cost f. Safety Stock Carrying cost g. COGS h. Total Cost of the inventory plan III BMAL340-M861 Application ... > Week 5 Instructions Based on the information provided in this case study, you will create a 2021 inventory plan for Surf Shaper. Use the following spreadsheet, as well as the formulas you learned and practiced last week, to answer the prompts below: Surf Shaper Case Study Surf Shaper Case Study - Spreadsheet with 2021 Forecast 1. Create a Sales Forecast showing a 15% increase in sales over 2020. 2. Use the 2021 Sales Forecast, determine the amount of Safety Stock Surf Shaper should keep on-hand to meet their service level goal. 3. Use the EOQ method to identify: The optimal order quantity (Q*) The number of orders to be completed The Re-Order Point Total ordering cost Inventory carrying cost Safety Stock Carrying cost COGS Total cost of the inventory plan . B B C D E F G H 2019 Cog 2018 790 853 Inventory Holding Cos Standard Deviation of Sa January February March April May June July August September October November December Total 800 1,300 1,560 1,620 1,970 2,140 2,230 1,560 1,280 1,070 940 17.260 864 1,404 1,685 1,750 2,128 2,311 2,408 1,685 1,382 1,156 1.015 18.641 2020 929 944 1,544 1,943 2,469 2,584 2,539 2,541 2,426 1,573 1,271 976 21.740 Sales Forecast 2021 January February March April May June July August September October November December Total Maximum Inventory, Average Invento Number Re-or Total Orde Inventory Car Safety Stock Car Total Cost of Inver Sheet1 G H K M N Cost per unit Inventory Holding Cost per unit Z-score Standard Deviation of Demand Safety Stock Sales Forecast 2021 January February March April May June July August September October November December Total EOQ (Q*) Maximum Inventory, (Q* + SS) Average Inventory, (Q*/2) Number of Orders Re-order Point Total Ordering Cost Inventory Carrying Cost Safety Stock Carrying Cost MIO COGS Total Cost of Inventory Plan SURF SHAPER CASE STUDY Surf Shaper, a surf warehouse in California, serves over 300 surf shops and retailers along the California coast. Surf Shaper places their boards in surf shops on consignment and replaces the consignment stock from their warehouse as boards are sold, typically within three days. Inventory must be carefully managed. If the retail surf shops run out of Surf Shaper boards before the consignment inventory is replaced, sales may be lost as customers choose other vendors. Surf Shaper may also lose their "shelf space" within the retailer's shop if their supply chain proves unreliable. For this reason, Surf Shaper strives to maintain a 96% service level with their retailers. 800 The best-selling board for Surf Shaper is the Grommet, their 8-foot foam wide board, that is suitable for beginners and casual surfers. The Grommet retails for $400, and COGS is $150 per unit. The popularity of the Grommet has been steadily increasing over the past three years. The unit sales report is displayed below. 2018) 2019 2020 January 790 853 929 February 8641 944 March 1,300 1,404 1,544 April 1,560 1,685 1,943 May 1,6201 1,750 2,469 June 1,970 2,128 2,584 July 2,140 2,311 2,539 August 2,230 2,408 2,541 September 1,560 1,685 2,426 October 1,280 1,382 1,573 November 1,070 1,156) 1,271 December 940 1,015 976 Total 17,260 18,641 21,740 SURF SHAPER CASE STUDY The Grommet is manufactured in Thailand. Orders take 30 days to arrive via sea freight. With the costs of communications, customs, and freight, each order placed incurs an expenditure of $935. Once the boards arrive at the warehouse, the inventory carrying cost is 15% per year/per unit of the COGS. Based on the information provided in this case study, you will create a 2021 inventory plan for Surf Shaper. Using the spreadsheet provided and the formulas you learned and practiced last week: 1. Create a Sales Forecast showing a 15% increase in sales over 2020. 2. Using your 2021 Sales Forecast, determine the amount of Safety Stock Surf Shapers should keep on-hand to meet their service level goal. 3. Utilizing the EOQ method, identify: a. The optimal order quantity (Q*) b. The number of orders to be completed c. The Re-Order Point d. Total ordering cost e. Inventory carrying cost f. Safety Stock Carrying cost g. COGS h. Total Cost of the inventory plan III BMAL340-M861 Application ... > Week 5 Instructions Based on the information provided in this case study, you will create a 2021 inventory plan for Surf Shaper. Use the following spreadsheet, as well as the formulas you learned and practiced last week, to answer the prompts below: Surf Shaper Case Study Surf Shaper Case Study - Spreadsheet with 2021 Forecast 1. Create a Sales Forecast showing a 15% increase in sales over 2020. 2. Use the 2021 Sales Forecast, determine the amount of Safety Stock Surf Shaper should keep on-hand to meet their service level goal. 3. Use the EOQ method to identify: The optimal order quantity (Q*) The number of orders to be completed The Re-Order Point Total ordering cost Inventory carrying cost Safety Stock Carrying cost COGS Total cost of the inventory plan . B B C D E F G H 2019 Cog 2018 790 853 Inventory Holding Cos Standard Deviation of Sa January February March April May June July August September October November December Total 800 1,300 1,560 1,620 1,970 2,140 2,230 1,560 1,280 1,070 940 17.260 864 1,404 1,685 1,750 2,128 2,311 2,408 1,685 1,382 1,156 1.015 18.641 2020 929 944 1,544 1,943 2,469 2,584 2,539 2,541 2,426 1,573 1,271 976 21.740 Sales Forecast 2021 January February March April May June July August September October November December Total Maximum Inventory, Average Invento Number Re-or Total Orde Inventory Car Safety Stock Car Total Cost of Inver Sheet1 G H K M N Cost per unit Inventory Holding Cost per unit Z-score Standard Deviation of Demand Safety Stock Sales Forecast 2021 January February March April May June July August September October November December Total EOQ (Q*) Maximum Inventory, (Q* + SS) Average Inventory, (Q*/2) Number of Orders Re-order Point Total Ordering Cost Inventory Carrying Cost Safety Stock Carrying Cost MIO COGS Total Cost of Inventory Plan

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started