Answered step by step

Verified Expert Solution

Question

1 Approved Answer

BIOMASS BOILER OPERATION ANALYSIS A fuel silo stores the biomass waste fuel and is fed into the boiler using a conveyor system. Combustion air

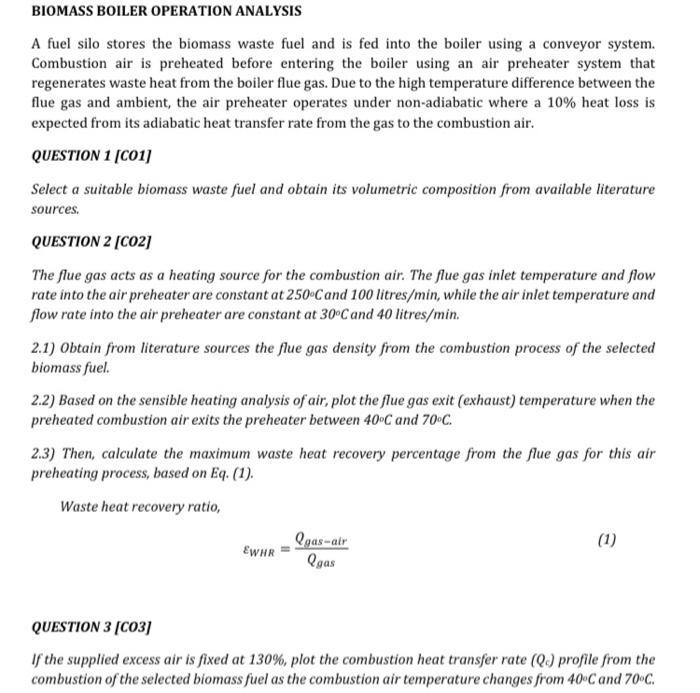

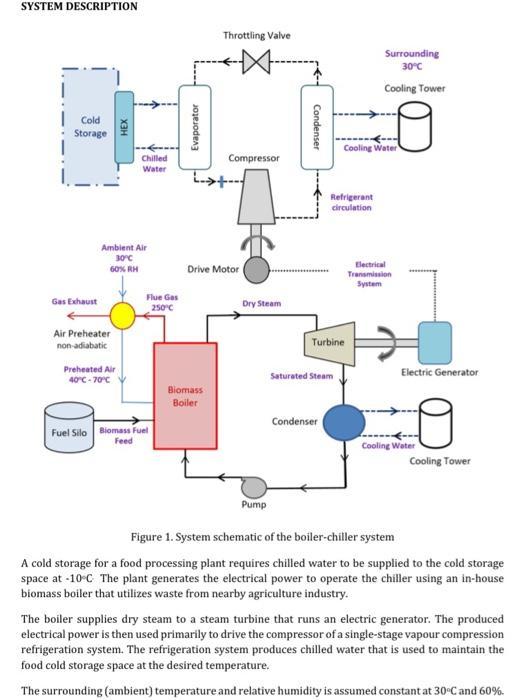

BIOMASS BOILER OPERATION ANALYSIS A fuel silo stores the biomass waste fuel and is fed into the boiler using a conveyor system. Combustion air is preheated before entering the boiler using an air preheater system that regenerates waste heat from the boiler flue gas. Due to the high temperature difference between the flue gas and ambient, the air preheater operates under non-adiabatic where a 10% heat loss is expected from its adiabatic heat transfer rate from the gas to the combustion air. QUESTION 1 [C01] Select a suitable biomass waste fuel and obtain its volumetric composition from available literature sources. QUESTION 2 [CO2] The flue gas acts as a heating source for the combustion air. The flue gas inlet temperature and flow rate into the air preheater are constant at 250C and 100 litres/min, while the air inlet temperature and flow rate into the air preheater are constant at 30C and 40 litres/min. 2.1) Obtain from literature sources the flue gas density from the combustion process of the selected biomass fuel. 2.2) Based on the sensible heating analysis of air, plot the flue gas exit (exhaust) temperature when the preheated combustion air exits the preheater between 40C and 70C. 2.3) Then, calculate the maximum waste heat recovery percentage from the flue gas for this air preheating process, based on Eq. (1). Waste heat recovery ratio, EWHR Qgas-air Qgas (1) QUESTION 3 [CO3] If the supplied excess air is fixed at 130%, plot the combustion heat transfer rate (Qc) profile from the combustion of the selected biomass fuel as the combustion air temperature changes from 40C and 70C. SYSTEM DESCRIPTION Cold Storage Gas Exhaust Air Preheater non-adiabatic HEX Ambient Air 30C 60% RH Preheated Air 40C-70C Chilled Water Flue Gas 250C Fuel Silo Biomass Fuel Feed Evaporator Throttling Valve Biomass Boiler Compressor Drive Motor Dry Steam Pump Condenser Refrigerant circulation Turbine Saturated Steam Condenser Cooling Water Surrounding 30C Cooling Tower Electrical Transmission System Cooling V Electric Generator Cooling Tower Figure 1. System schematic of the boiler-chiller system A cold storage for a food processing plant requires chilled water to be supplied to the cold storage space at -10C The plant generates the electrical power to operate the chiller using an in-house biomass boiler that utilizes waste from nearby agriculture industry. The boiler supplies dry steam to a steam turbine that runs an electric generator. The produced electrical power is then used primarily to drive the compressor of a single-stage vapour compression refrigeration system. The refrigeration system produces chilled water that is used to maintain the food cold storage space at the desired temperature. The surrounding (ambient) temperature and relative humidity is assumed constant at 30C and 60%

Step by Step Solution

★★★★★

3.44 Rating (160 Votes )

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started