Question: TABLE 3-11 CONTINUED Flow (L/min) Sink Max. allowable fines concentration (%) 315 0.000 930 0.018 460 0.018 30 0.018 30 0.018 315 0.0 0.000 0.0

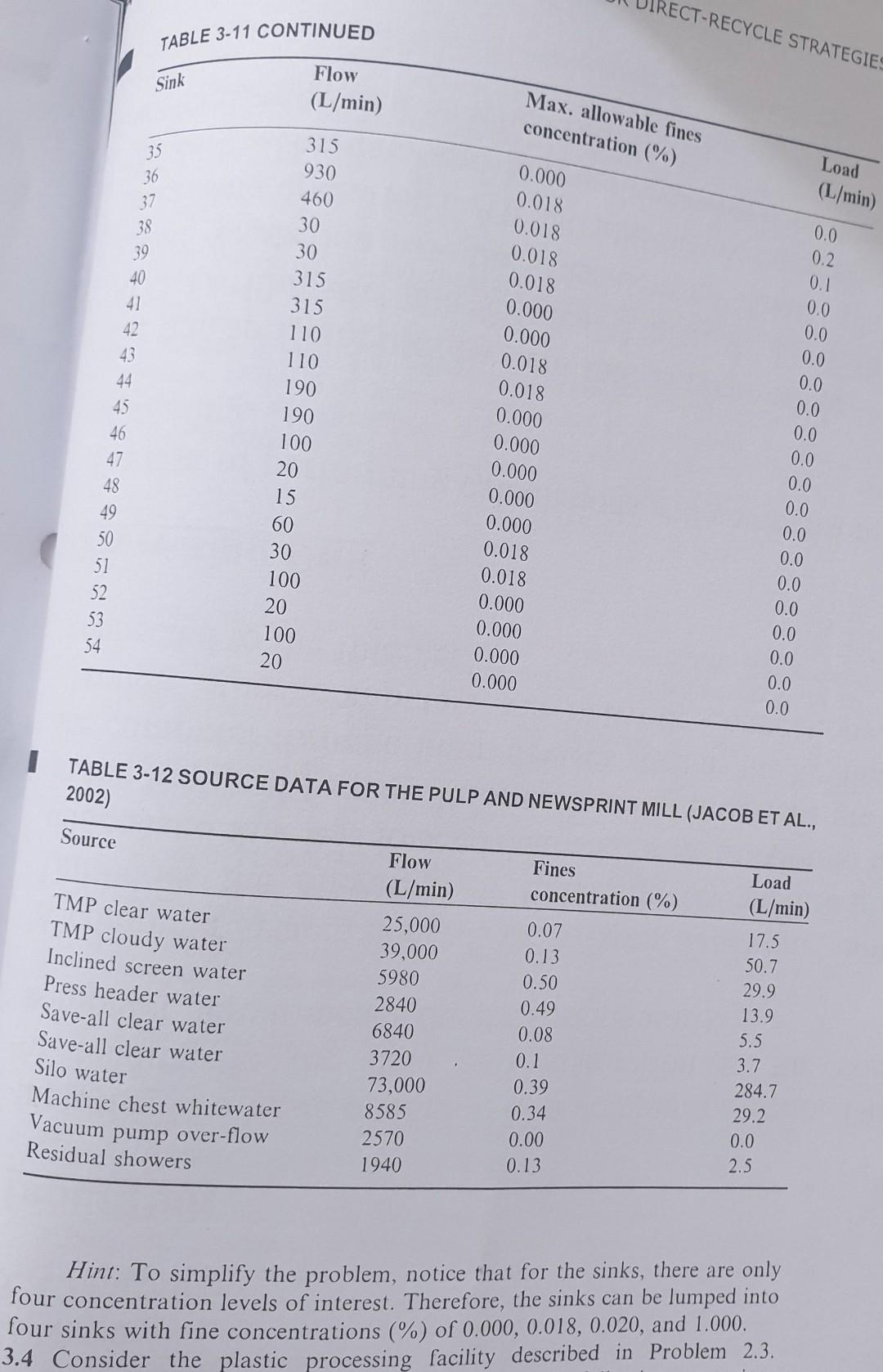

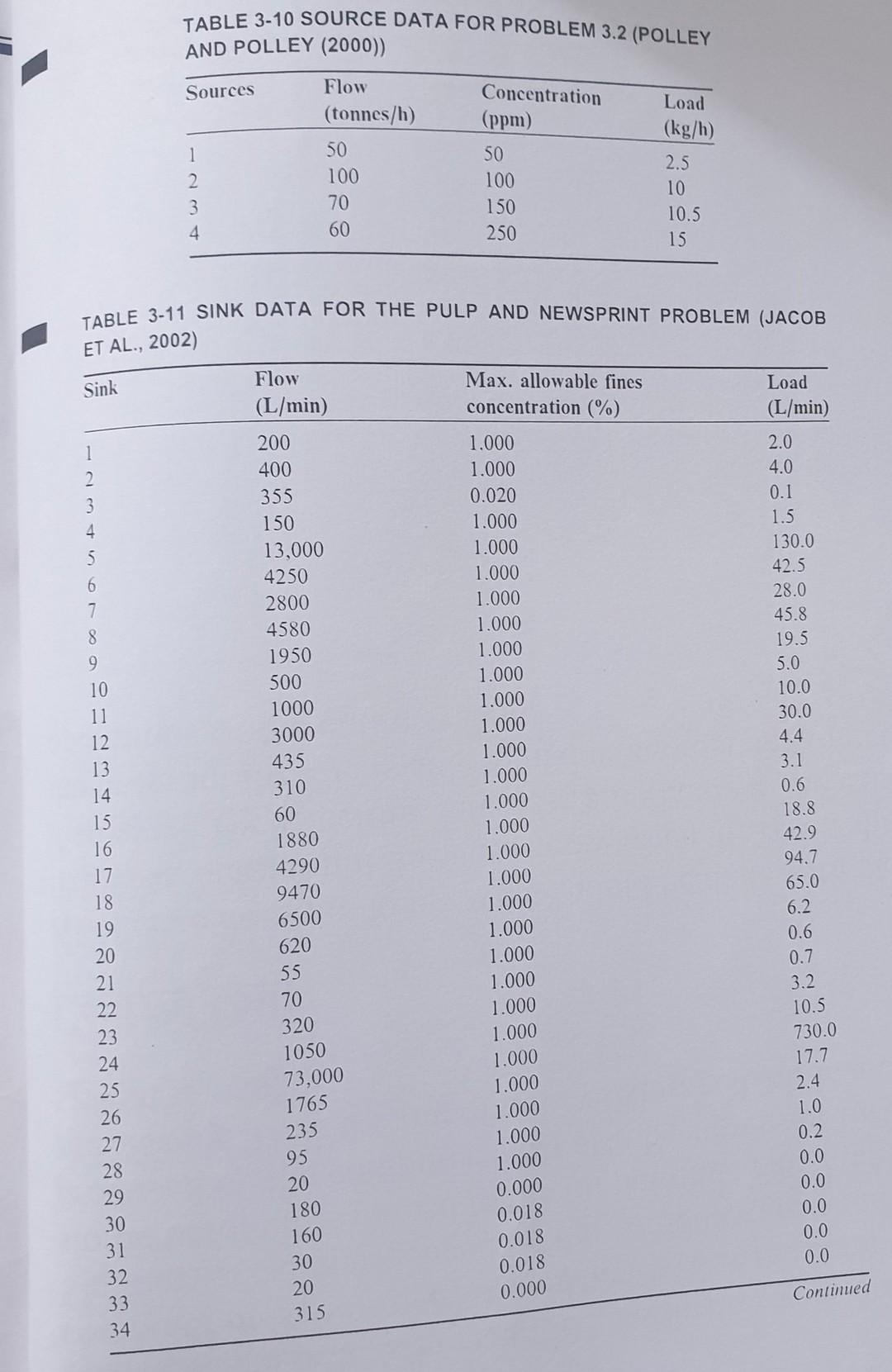

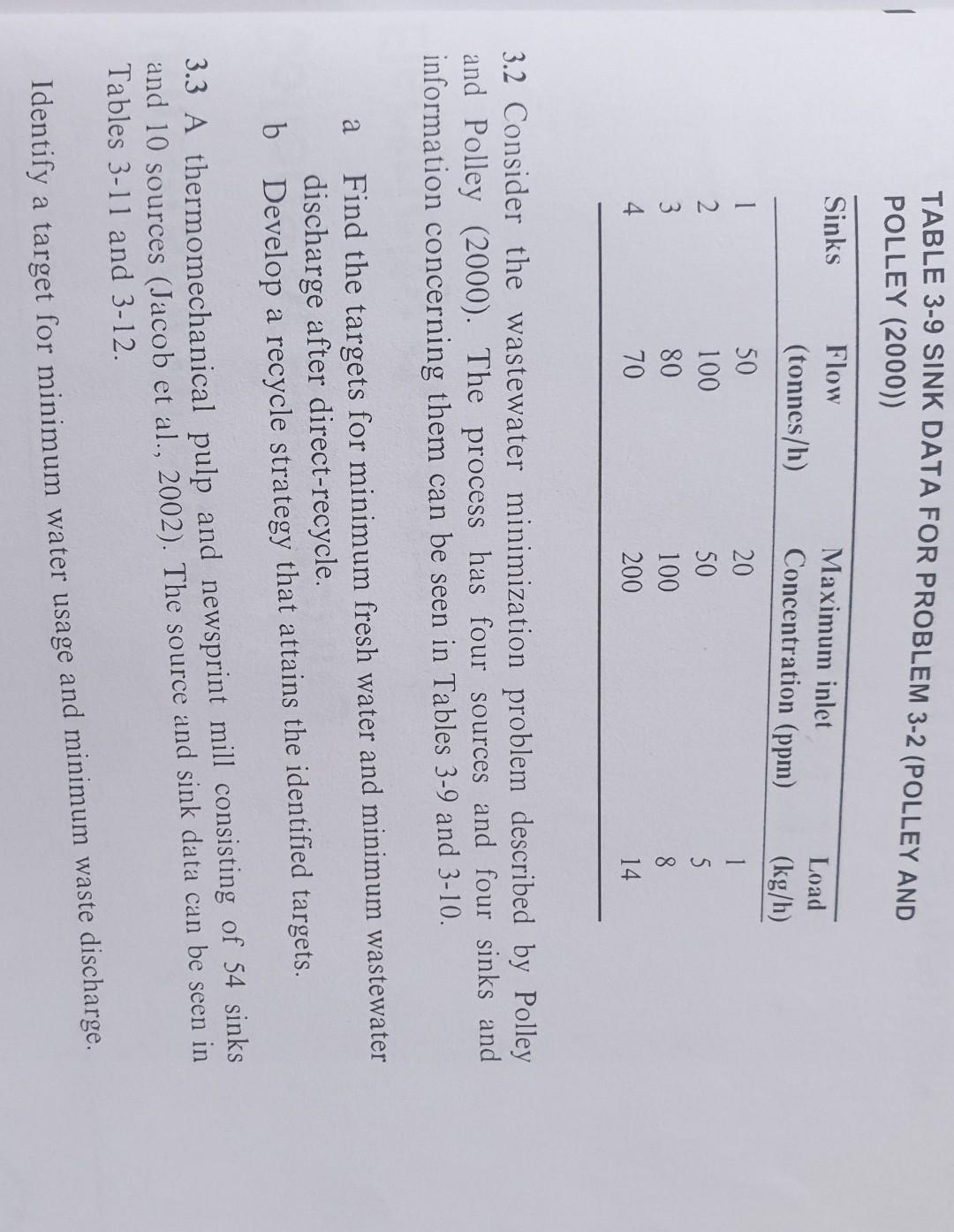

TABLE 3-11 CONTINUED Flow (L/min) Sink Max. allowable fines concentration (%) 315 0.000 930 0.018 460 0.018 30 0.018 30 0.018 315 0.0 0.000 0.0 315 0.000 0.0 110 0.018 0.0 110 0.018 0.0 190 0.000 0.0 190 0.000 0.0 100 0.000 0.0 20 0.0 0.000 15 0.0 0.000 60 0.0 0.018 30 0.0 0.018 100 0.0 0.000 52 20 0.0 0.000 0.0 53 100 0.000 0.0 54 20 0.000 0.0 TABLE 3-12 SOURCE DATA FOR THE PULP AND NEWSPRINT MILL (JACOB ET AL., 2002) Source Flow Fines Load (L/min) (L/min) concentration (%) TMP clear water 17.5 25,000 0.07 TMP cloudy water 50.7 39,000 0.13 29.9 Inclined screen water 5980 0.50 13.9 Press header water 2840 0.49 5.5 Save-all clear water 6840 0.08 3.7 0.1 Save-all clear water 3720 284.7 Silo water 73,000 0.39 29.2 0.34 8585 0.0 0.00 2570 Machine chest whitewater Vacuum pump over-flow Residual showers 2.5 0.13 1940 Hint: To simplify the problem, notice that for the sinks, there are only four concentration levels of interest. Therefore, the sinks can be lumped into four sinks with fine concentrations (%) of 0.000, 0.018, 0.020, and 1.000. 3.4 Consider the plastic processing facility described in Problem 2.3. 46 47 48 49 50 51 45 43 44 41 42 40 35 37 39 SSSSSSSSSSS 36 38 RECT-RECYCLE STRATEGIES Load (L/min) 0.0 0.2 0.1 Sources TABLE 3-10 SOURCE DATA FOR PROBLEM 3.2 (POLLEY AND POLLEY (2000)) Flow Concentration Load (tonnes/h) (ppm) (kg/h) 1 50 50 2.5 2. 100 100 10 3 70 150 10.5 4 60 250 15 TABLE 3-11 SINK DATA FOR THE PULP AND NEWSPRINT PROBLEM (JACOB ET AL., 2002) Sink Max. allowable fines concentration (%) Load (L/min) 1 2 3 4 5 6 7 8 9 Flow (L/min) 200 400 355 150 13,000 4250 2800 4580 1950 500 1000 3000 435 310 1.000 1.000 0.020 1.000 1.000 1.000 1.000 1.000 1.000 1.000 1.000 1.000 1.000 1.000 1.000 1.000 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 60 1880 4290 9470 6500 620 55 70 320 1050 73,000 1765 235 95 20 180 160 30 20 315 1.000 1.000 1.000 1.000 1.000 1.000 1.000 1.000 1.000 1.000 1.000 1.000 1.000 0.000 0.018 0.018 0.018 0.000 2.0 4.0 0.1 1.5 130.0 42.5 28.0 45.8 19.5 5.0 10.0 30.0 4.4 3.1 0.6 18.8 42.9 94.7 65.0 6.2 0.6 0.7 3.2 10.5 730.0 17.7 2.4 1.0 0.2 0.0 0.0 0.0 0.0 0.0 Contimied 1 TABLE 3-9 SINK DATA FOR PROBLEM 3-2 (POLLEY AND POLLEY (2000)) Sinks Flow Maximum inlet Load (tonnes/h) Concentration (ppm) (kg/h) 1 50 20 1 2 100 50 3 80 100 4 70 200 14 3.2 Consider the wastewater minimization problem described by Polley and Polley (2000). The process has four sources and four sinks and information concerning them can be seen in Tables 3-9 and 3-10. a Find the targets for minimum fresh water and minimum wastewater discharge after direct-recycle. b Develop a recycle strategy that attains the identified targets. 3.3 A thermomechanical pulp and newsprint mill consisting of 54 sinks and 10 sources (Jacob et al., 2002). The source and sink data can be seen in Tables 3-11 and 3-12. Identify a target for minimum water usage and minimum waste discharge

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts