Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Task 4. Homework. Define a mass balance and amounts of separated waste fractions for the sorting facility which is handling MSW. Also define capacity

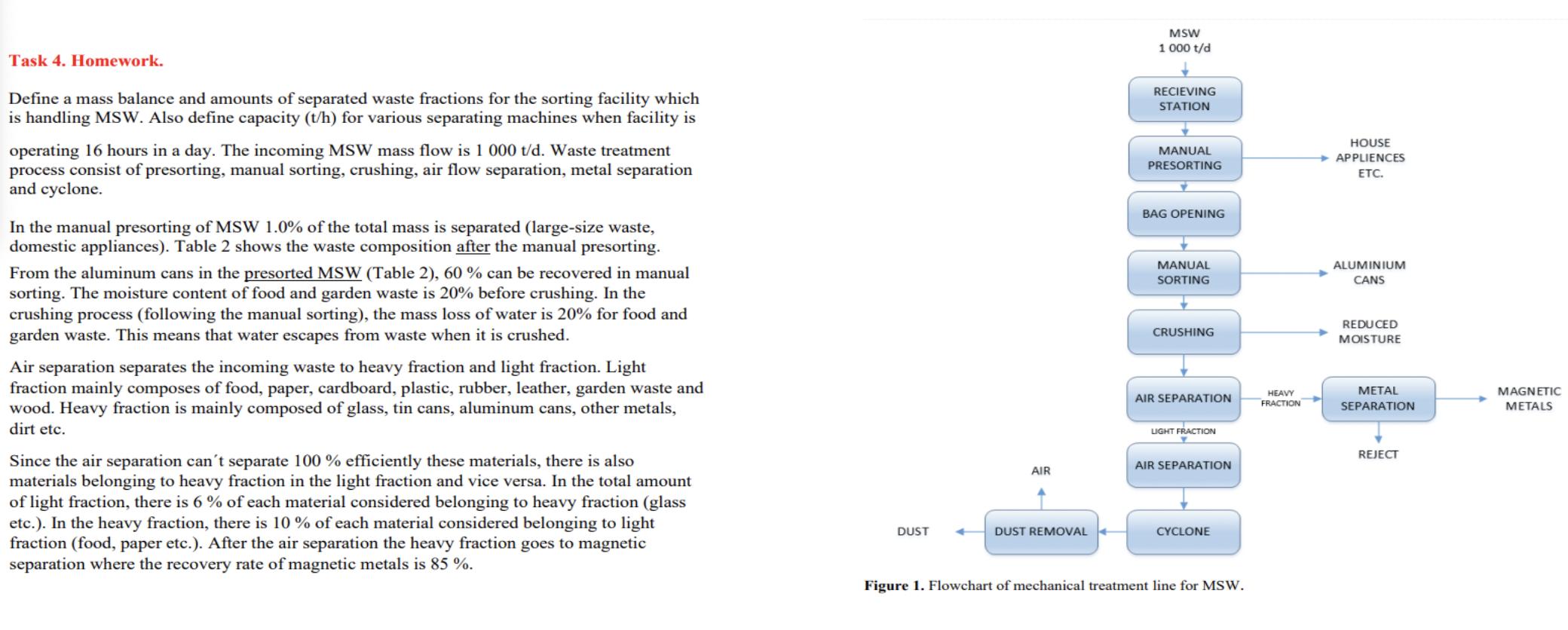

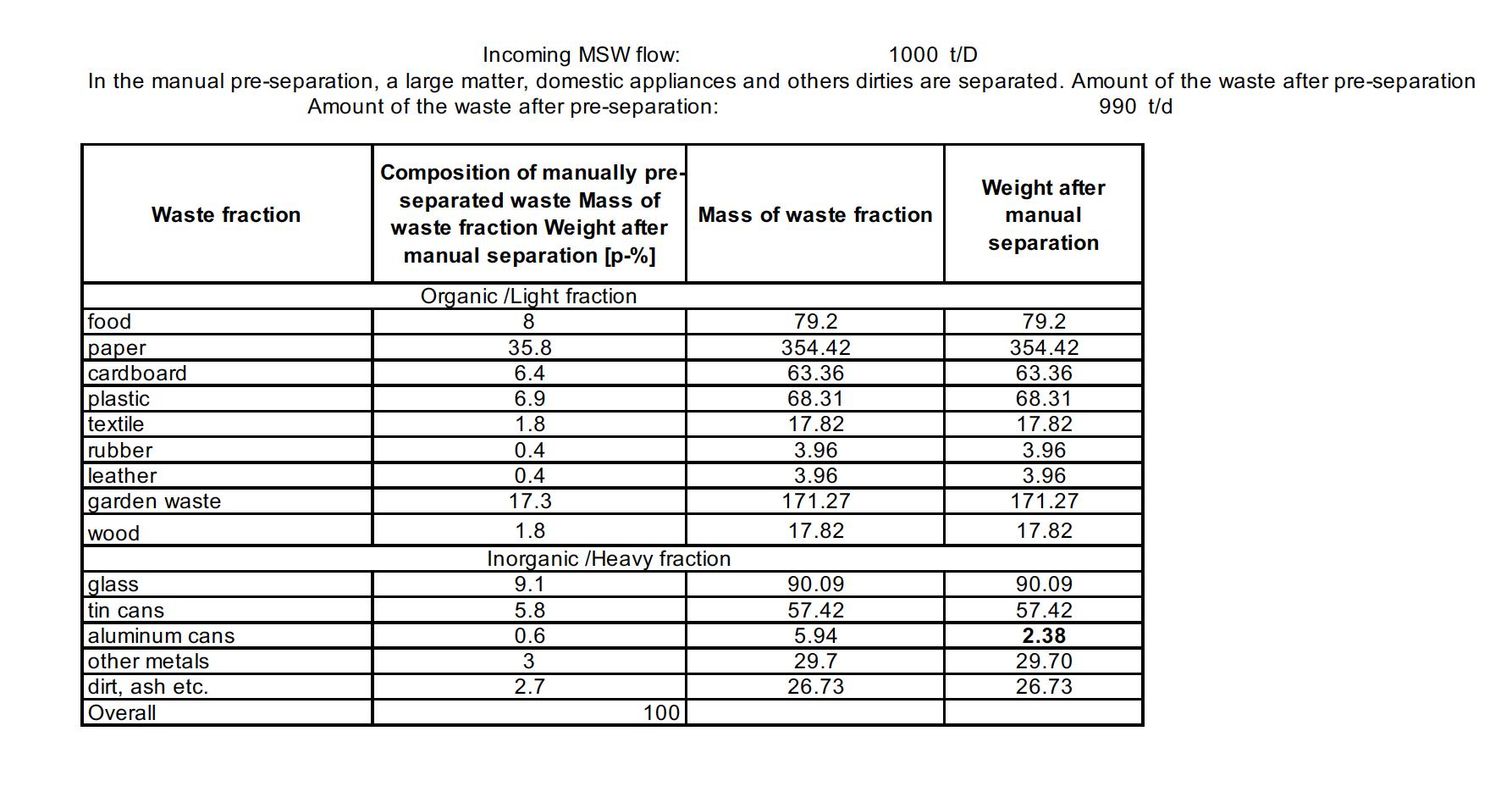

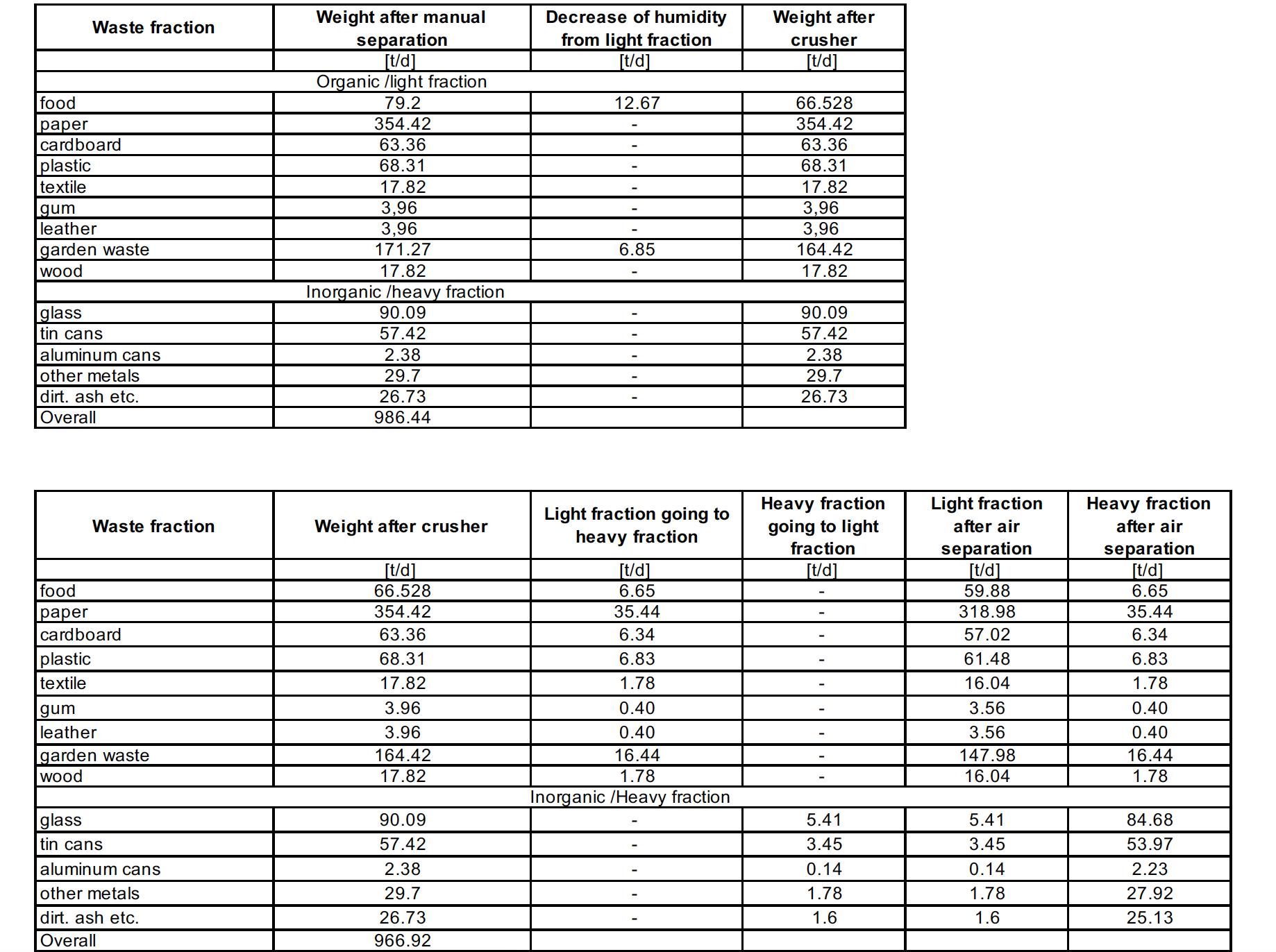

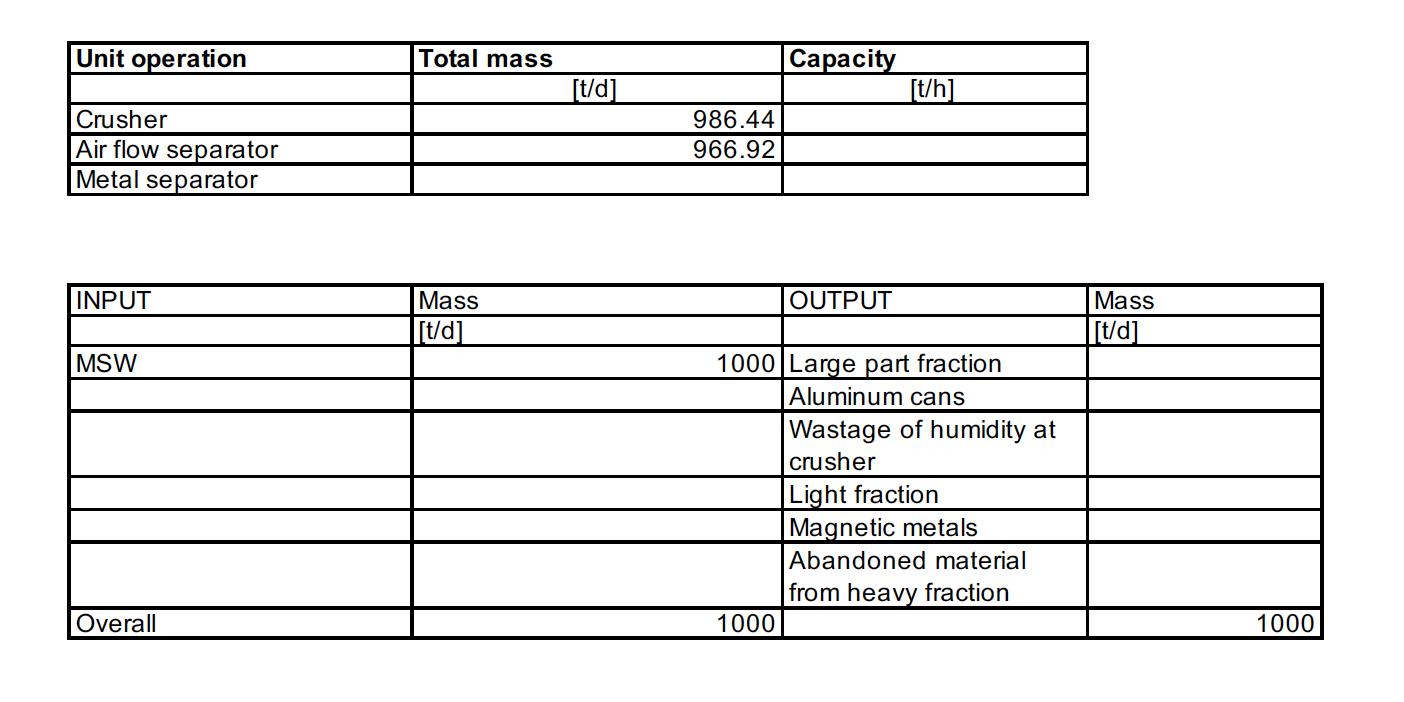

Task 4. Homework. Define a mass balance and amounts of separated waste fractions for the sorting facility which is handling MSW. Also define capacity (t/h) for various separating machines when facility is operating 16 hours in a day. The incoming MSW mass flow is 1 000 t/d. Waste treatment process consist of presorting, manual sorting, crushing, air flow separation, metal separation and cyclone. In the manual presorting of MSW 1.0% of the total mass is separated (large-size waste, domestic appliances). Table 2 shows the waste composition after the manual presorting. From the aluminum cans in the presorted MSW (Table 2), 60% can be recovered in manual sorting. The moisture content of food and garden waste is 20% before crushing. In the crushing process (following the manual sorting), the mass loss of water is 20% for food and garden waste. This means that water escapes from waste when it is crushed. Air separation separates the incoming waste to heavy fraction and light fraction. Light fraction mainly composes of food, paper, cardboard, plastic, rubber, leather, garden waste and wood. Heavy fraction is mainly composed of glass, tin cans, aluminum cans, other metals, dirt etc. Since the air separation can't separate 100% efficiently these materials, there is also materials belonging to heavy fraction in the light fraction and vice versa. In the total amount of light fraction, there is 6% of each material considered belonging to heavy fraction (glass etc.). In the heavy fraction, there is 10% of each material considered belonging to light fraction (food, paper etc.). After the air separation the heavy fraction goes to magnetic separation where the recovery rate of magnetic metals is 85 %. MSW 1 000 t/d RECIEVING STATION MANUAL PRESORTING HOUSE APPLIENCES ETC. BAG OPENING MANUAL SORTING ALUMINIUM CANS CRUSHING REDUCED MOISTURE AIR SEPARATION HEAVY FRACTION METAL SEPARATION MAGNETIC METALS LIGHT FRACTION AIR SEPARATION AIR DUST DUST REMOVAL CYCLONE Figure 1. Flowchart of mechanical treatment line for MSW. REJECT Incoming MSW flow: 1000 t/D In the manual pre-separation, a large matter, domestic appliances and others dirties are separated. Amount of the waste after pre-separation Amount of the waste after pre-separation: 990 t/d Waste fraction Composition of manually pre- separated waste Mass of waste fraction Weight after manual separation [p-%] Organic/Light fraction Weight after Mass of waste fraction manual separation food 8 79.2 79.2 paper 35.8 354.42 354.42 cardboard 6.4 63.36 63.36 plastic 6.9 68.31 68.31 textile 1.8 17.82 17.82 rubber 0.4 3.96 3.96 leather 0.4 3.96 3.96 garden waste 17.3 171.27 171.27 wood 1.8 17.82 17.82 Inorganic /Heavy fraction glass 9.1 90.09 90.09 tin cans 5.8 57.42 57.42 aluminum cans 0.6 5.94 2.38 other metals 3 29.7 29.70 dirt, ash etc. 2.7 26.73 26.73 Overall 100 food paper Waste fraction cardboard plastic textile gum leather Weight after manual separation [t/d] Organic /light fraction 79.2 Decrease of humidity from light fraction [t/d] 12.67 Weight after crusher [t/d] 66.528 354.42 63.36 68.31 17.82 3,96 3,96 171.27 17.82 garden waste wood glass tin cans aluminum cans other metals dirt. ash etc. Overall Inorganic /heavy fraction 90.09 57.42 2.38 29.7 26.73 986.44 354.42 63.36 68.31 17.82 3,96 3,96 6.85 164.42 17.82 90.09 57.42 2.38 29.7 26.73 Waste fraction Weight after crusher Light fraction going to heavy fraction [t/d] [t/d] Heavy fraction going to light fraction [t/d] Light fraction after air separation Heavy fraction after air separation [t/d] [t/d] food 66.528 6.65 59.88 6.65 paper 354.42 35.44 318.98 35.44 cardboard 63.36 6.34 57.02 6.34 plastic 68.31 6.83 61.48 6.83 textile 17.82 1.78 16.04 1.78 gum 3.96 0.40 3.56 0.40 leather 3.96 0.40 3.56 0.40 garden waste 164.42 16.44 147.98 16.44 wood 17.82 1.78 16.04 1.78 Inorganic/Heavy fraction glass 90.09 5.41 5.41 84.68 tin cans 57.42 3.45 3.45 53.97 aluminum cans 2.38 0.14 0.14 2.23 other metals 29.7 1.78 1.78 27.92 dirt. ash etc. 26.73 1.6 1.6 25.13 Overall 966.92 Unit operation Total mass [t/d] Crusher Air flow separator Metal separator 986.44 966.92 INPUT MSW Overall Capacity [t/h] Mass [t/d] OUTPUT 1000 Large part fraction Aluminum cans Wastage of humidity at crusher Light fraction Magnetic metals Abandoned material 1000 from heavy fraction Mass [t/d] 1000

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started