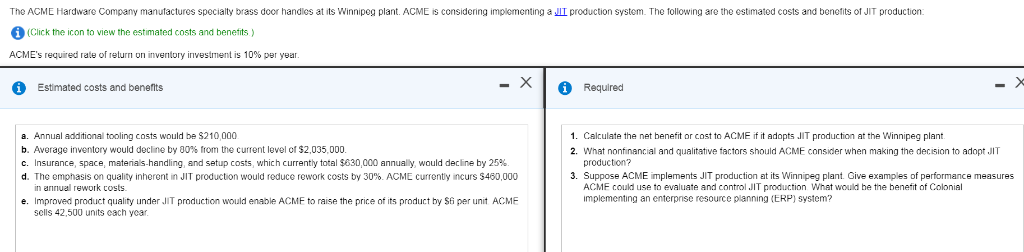

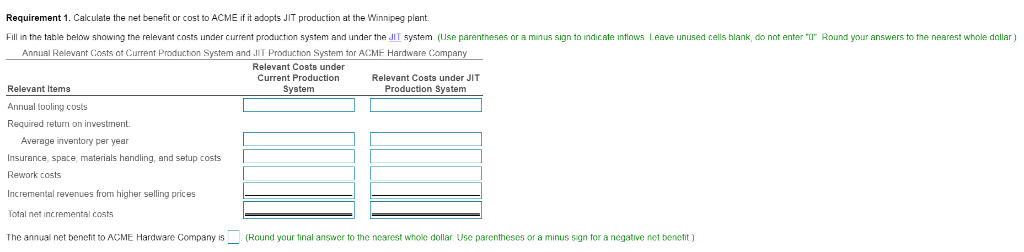

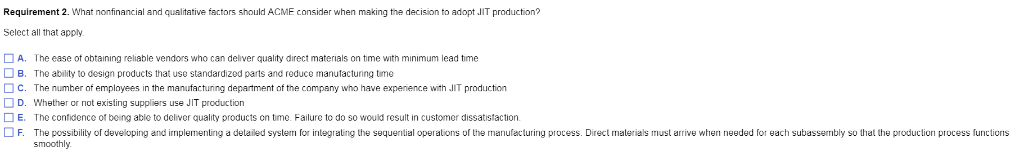

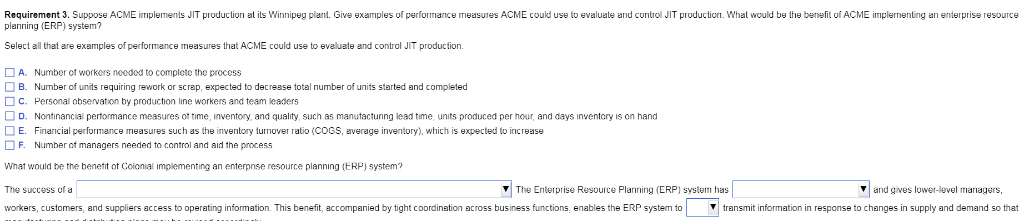

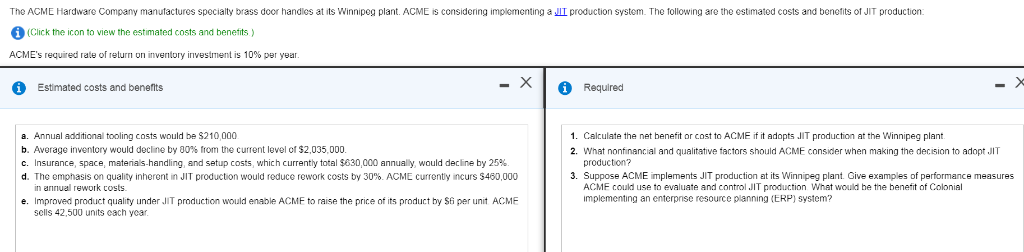

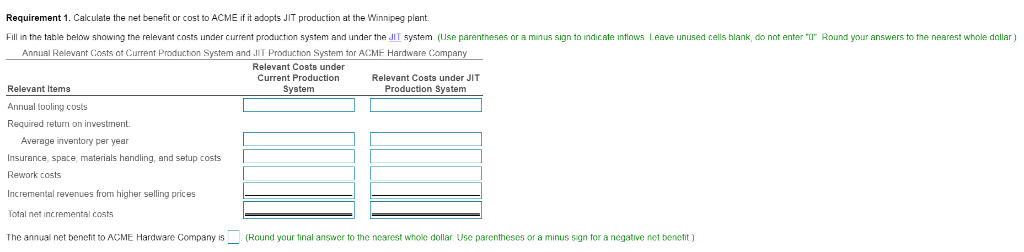

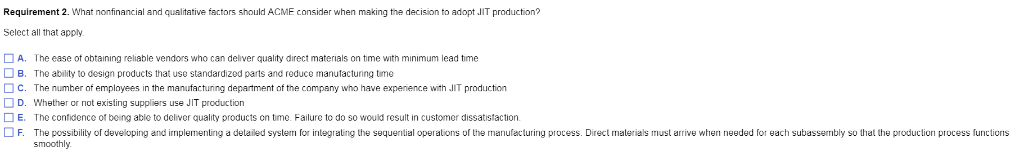

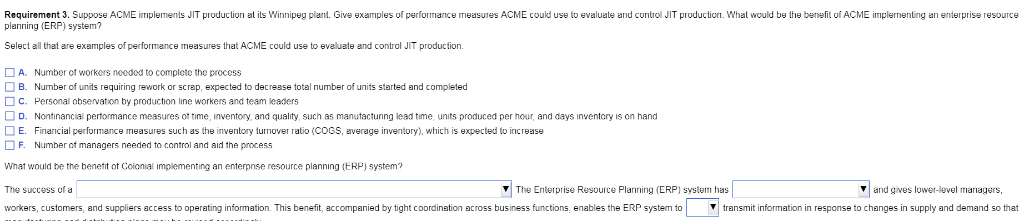

The ACME Hardware Company manufactures specialty brass door handles at its Winnipeg plant. ACME is considering implementing a JIT production system. The following are the estimated costs and benefits of JIT production (Click the icon to view the estimated costs and benefits) ACME's required rate of return on inventory investment is 10% per year. A Estimated costs and benefits - X A Required a. Annual additional tooling costs would be $210,000 b. Average inventory would decline by 30% from the current level of $2,035,000 c. Insurance, space, materials.handling, and setup costs, which currently total $630,000 annually would decline by 25% d. The omphasis on quality inherent in JIT production would reduce rework costs by 30% ACME currently incurs $480,000 in annual rework costs. e. Improved product quality under JIT production would enable ACME to raise the price of its product by S6 per unit ACME sells 42.500 units cach year 1. Calculate the net benefit or cost to ACME if it adopts JIT production at the Winnipeg plant 2. What nonfinancial and qualitative factors should ACME consider when making the decision to adopt JIT production? 3. Suppose ACME implements JIT production at its Winnipeg plant. Give examples of performance measures ACME could use to evaluate and control JIT production What would be the benefit of Colonial implementing an enterprise resource planning (ERP) system? Requirement 1. Calculate the net benefit or cost to ACME if it adopts JIT production at the Winnipeg plant. Fill in the table below showing the relevant costs under current production system and under the JIT system (Use parentheses or a minus sign to indicate inflows Leave unused cells blank do not enter "0" Round your answers to the nearest whole dollar) Annual Relevant Costs of Current Production System and IT Production System for ACME Hardware Company Relevant Costs under Current Production Relevant Costs under JIT Relevant Items System Production System Annual tooling costs Required return on investment. Average inventory per year Insurance, space, materials handling, and setup costs Rework costs Incremental revenues from higher selling prices Total net incremental costs The annual net benefit to ACME Hardware Company is (Round your final answer to the nearest whole dollar Use parentheses or a minus sign for a negative net benefit.) Requirement 2. What nonfinancial and qualitative factors should ACME consider when making the decision to adopt JIT production? Select all that apply DA. The ease of obtaining reliable vendors who can deliver quality direct materials on time with minimum lead time DB. The ability to design products that use standardized parts and reduce manufacturing timo C. The number of employees in the manufacturing department of the company who have experience with JIT production DD. Whether or not existing suppliers use JIT production DE. The confidence of being able to deliver quality products on time Failure to do so would result in customer dissatisfaction DE The possibility of developing and implementing a detailed system for integrating the sequential operations of the manufacturing process. Direct materials must arrive when needed for each subassembly so that the production process functions smoothly Requirement 3. Suppose ACME implements JIT production at its Winnipeg plant. Give uxamples of performance measures ACME could use to evaluate and control JIT production. What would be the benefit of ACME implementing an enterprise resource planning (ERP) system? Select all that are examples of performance measures that ACME could use to evaluate and control JIT production DA Number of workers needed to complete the process DB. Number of units requiring rework or scrap, expected to decrease total number of units started and completed DC Personal observation by production line workers and team leaders D. Nontinancial performance measures of time, inventory and quality, such as manufacturing lead time units produced per hour and days inventory is on hand E. Financial performance measures such as the inventory turnover ratio (COGS, average inventory), which is expected to increase DE Number of managers needed to control and aid the process What would be the benefit of Colonial implementing an enterprise resource planning (ERP) system? The success of a The Enterprise Resource Planning (ERP) system has and gives lower-level managers, workers, customers, and suppliers access to operating information. This benefit, accompanied by tight coordination across business functions, enables the ERP system to transmit information in response to changes in supply and demand so that