Answered step by step

Verified Expert Solution

Question

1 Approved Answer

The Bully Boy Bagging Line Things were not going well at Bully Boy Products (BBP). BBP was a regional producer of organic fertilizer, potting

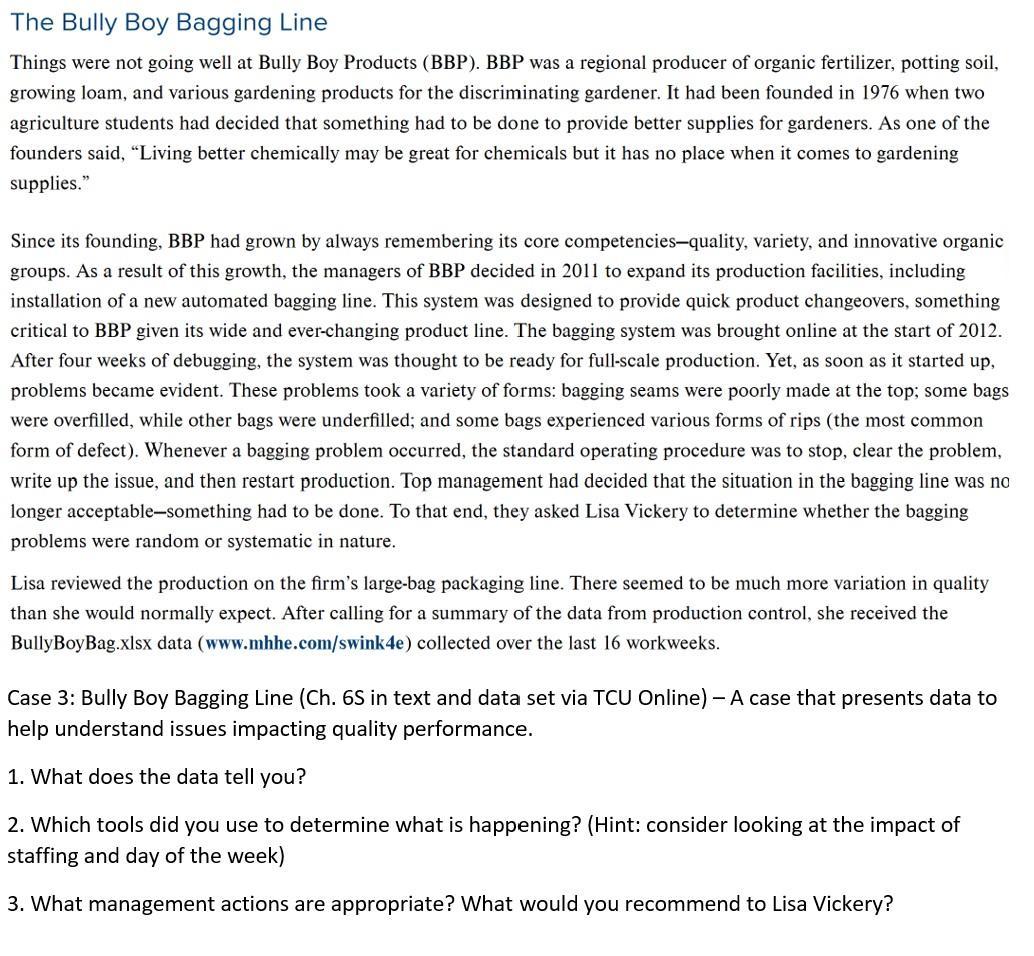

The Bully Boy Bagging Line Things were not going well at Bully Boy Products (BBP). BBP was a regional producer of organic fertilizer, potting soil, growing loam, and various gardening products for the discriminating gardener. It had been founded in 1976 when two agriculture students had decided that something had to be done to provide better supplies for gardeners. As one of the founders said, "Living better chemically may be great for chemicals but it has no place when it comes to gardening supplies." Since its founding, BBP had grown by always remembering its core competencies-quality, variety, and innovative organic groups. As a result of this growth, the managers of BBP decided in 2011 to expand its production facilities, including installation of a new automated bagging line. This system was designed to provide quick product changeovers, something critical to BBP given its wide and ever-changing product line. The bagging system was brought online at the start of 2012. After four weeks of debugging, the system was thought to be ready for full-scale production. Yet, as soon as it started up, problems became evident. These problems took a variety of forms: bagging seams were poorly made at the top; some bags were overfilled, while other bags were underfilled; and some bags experienced various forms of rips (the most common form of defect). Whenever a bagging problem occurred, the standard operating procedure was to stop, clear the problem, write up the issue, and then restart production. Top management had decided that the situation in the bagging line was no longer acceptable-something had to be done. To that end, they asked Lisa Vickery to determine whether the bagging problems were random or systematic in nature. Lisa reviewed the production on the firm's large-bag packaging line. There seemed to be much more variation in quality than she would normally expect. After calling for a summary of the data from production control, she received the BullyBoyBag.xlsx data (www.mhhe.com/swink4e) collected over the last 16 workweeks. Case 3: Bully Boy Bagging Line (Ch. 6S in text and data set via TCU Online) - A case that presents data to help understand issues impacting quality performance. 1. What does the data tell you? 2. Which tools did you use to determine what is happening? (Hint: consider looking at the impact of staffing and day of the week) 3. What management actions are appropriate? What would you recommend to Lisa Vickery?

Step by Step Solution

There are 3 Steps involved in it

Step: 1

The rejection indicates that the provided initial answer was a repeated request for more information even though the full question was already availab...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started