Answered step by step

Verified Expert Solution

Question

1 Approved Answer

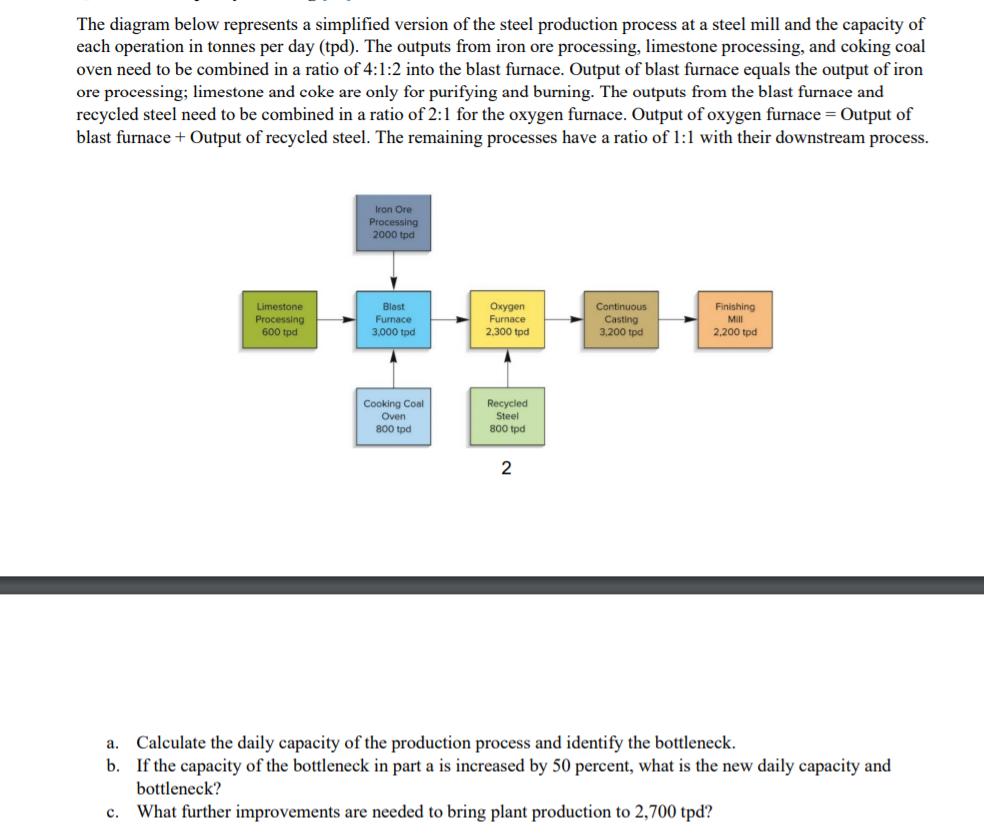

The diagram below represents a simplified version of the steel production process at a steel mill and the capacity of each operation in tonnes

The diagram below represents a simplified version of the steel production process at a steel mill and the capacity of each operation in tonnes per day (tpd). The outputs from iron ore processing, limestone processing, and coking coal oven need to be combined in a ratio of 4:1:2 into the blast furnace. Output of blast furnace equals the output of iron ore processing; limestone and coke are only for purifying and burning. The outputs from the blast furnace and recycled steel need to be combined in a ratio of 2:1 for the oxygen furnace. Output of oxygen furnace = Output of blast furnace + Output of recycled steel. The remaining processes have a ratio of 1:1 with their downstream process. tron Ore Processing 2000 tpd Blost n Furnace Continuous Casting 3,200 tpd Finishing Limestone Processing 600 tpd Furnace 3,000 tpd Mill 2,300 tpd 2.200 tod Cooking Coal Oven Recycled Steel 800 tpd 800 tpd 2 a. Calculate the daily capacity of the production process and identify the bottleneck. b. If the capacity of the bottleneck in part a is increased by 50 percent, what is the new daily capacity and bottleneck? c. What further improvements are needed to bring plant production to 2,700 tpd?

Step by Step Solution

★★★★★

3.38 Rating (154 Votes )

There are 3 Steps involved in it

Step: 1

The limstone and coking coal ovens ratio dependcey with Iron ore processing Iron 4 Limestone 1 Cooki...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Document Format ( 2 attachments)

636054eac6cd2_233815.pdf

180 KBs PDF File

636054eac6cd2_233815.docx

120 KBs Word File

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started