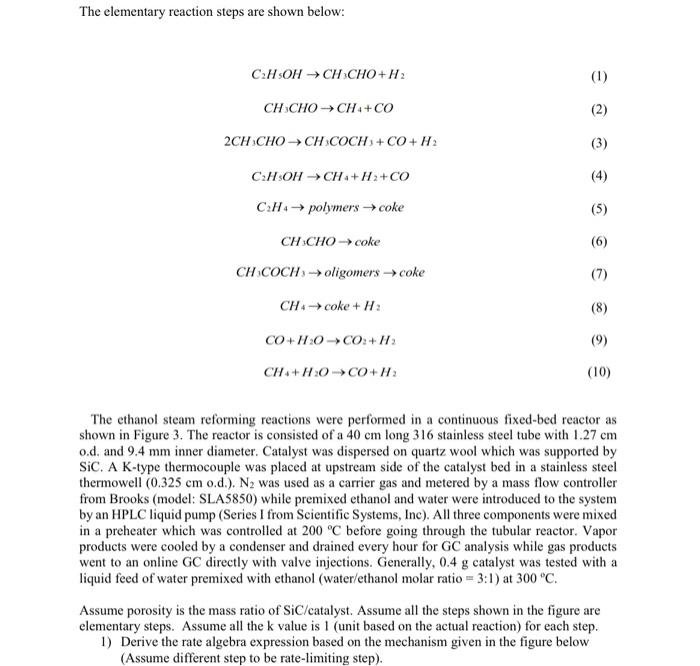

The elementary reaction steps are shown below: C2H5OHCH3CHO+H2CH3CHOCH4+CO2CH3CHOCH3COCH3+CO+H2C2HsOHCH4+H2+COC2H4polymerscokeCH3CHOcokeCH3COCH3oligomerscokeCH4coke+H2CO+H2OCO2+H2CH4+H2OCO+H2 The ethanol steam reforming reactions were performed in a continuous fixed-bed reactor as shown in Figure 3. The reactor is consisted of a 40cm long 316 stainless steel tube with 1.27cm o.d. and 9.4mm inner diameter. Catalyst was dispersed on quartz wool which was supported by SiC. A K-type thermocouple was placed at upstream side of the catalyst bed in a stainless steel thermowell ( 0.325cm o.d.). N2 was used as a carrier gas and metered by a mass flow controller from Brooks (model: SLA5850) while premixed ethanol and water were introduced to the system by an HPLC liquid pump (Series I from Scientific Systems, Inc). All three components were mixed in a preheater which was controlled at 200C before going through the tubular reactor. Vapor products were cooled by a condenser and drained every hour for GC analysis while gas products went to an online GC directly with valve injections. Generally, 0.4g catalyst was tested with a liquid feed of water premixed with ethanol (water/ethanol molar ratio =3:1 ) at 300C. Assume porosity is the mass ratio of SiC/ catalyst. Assume all the steps shown in the figure are elementary steps. Assume all the k value is 1 (unit based on the actual reaction) for each step. 1) Derive the rate algebra expression based on the mechanism given in the figure below The elementary reaction steps are shown below: C2H5OHCH3CHO+H2CH3CHOCH4+CO2CH3CHOCH3COCH3+CO+H2C2HsOHCH4+H2+COC2H4polymerscokeCH3CHOcokeCH3COCH3oligomerscokeCH4coke+H2CO+H2OCO2+H2CH4+H2OCO+H2 The ethanol steam reforming reactions were performed in a continuous fixed-bed reactor as shown in Figure 3. The reactor is consisted of a 40cm long 316 stainless steel tube with 1.27cm o.d. and 9.4mm inner diameter. Catalyst was dispersed on quartz wool which was supported by SiC. A K-type thermocouple was placed at upstream side of the catalyst bed in a stainless steel thermowell ( 0.325cm o.d.). N2 was used as a carrier gas and metered by a mass flow controller from Brooks (model: SLA5850) while premixed ethanol and water were introduced to the system by an HPLC liquid pump (Series I from Scientific Systems, Inc). All three components were mixed in a preheater which was controlled at 200C before going through the tubular reactor. Vapor products were cooled by a condenser and drained every hour for GC analysis while gas products went to an online GC directly with valve injections. Generally, 0.4g catalyst was tested with a liquid feed of water premixed with ethanol (water/ethanol molar ratio =3:1 ) at 300C. Assume porosity is the mass ratio of SiC/ catalyst. Assume all the steps shown in the figure are elementary steps. Assume all the k value is 1 (unit based on the actual reaction) for each step. 1) Derive the rate algebra expression based on the mechanism given in the figure below