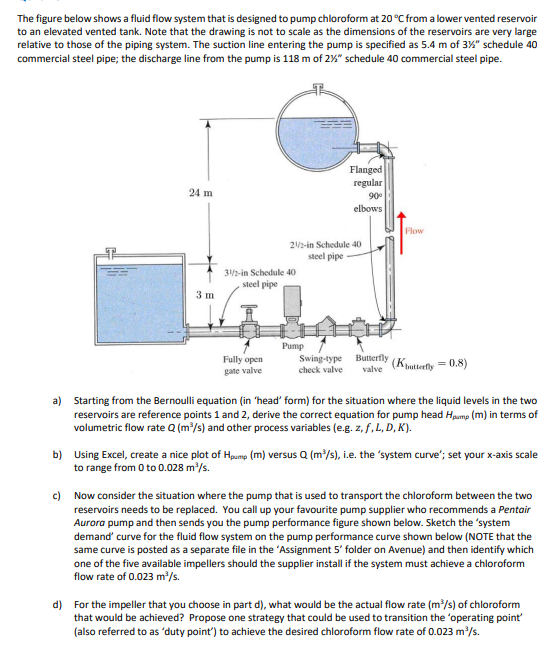

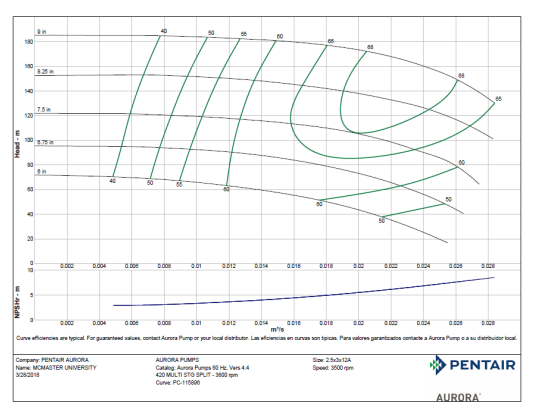

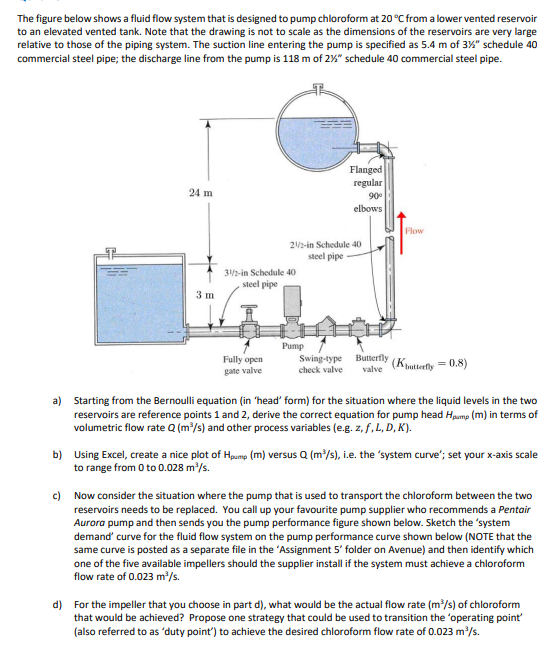

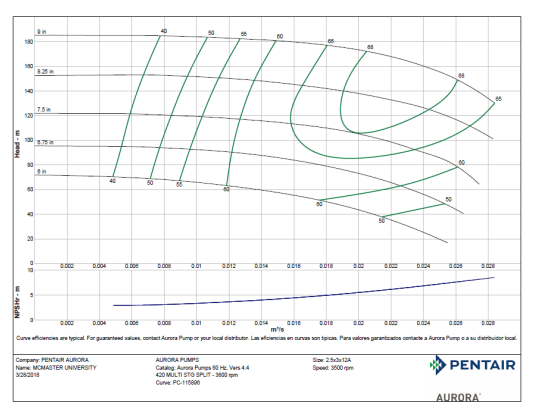

The figure below shows a fluid flow system that is designed to pump chloroform at 20C from a lower vented reservoir to an elevated vented tank. Note that the drawing is not to scale as the dimensions of the reservoirs are very large relative to those of the piping system. The suction line entering the pump is specified as 5.4 m of 34" schedule 40 commercial steel pipe; the discharge line from the pump is 118 m of 2%" schedule 40 commercial steel pipe. Flanged regular 24 m 90 elbows Flow 21/-in Schedule 40 steel pipe 31/-in Schedule 40 steel pipe 3 m Fully open Pump Swing-type Butterfly (Kattefly = 0.8) check valve gate valve a) Starting from the Bernoulli equation (in 'head' form) for the situation where the liquid levels in the two reservoirs are reference points 1 and 2, derive the correct equation for pump head Hpump (m) in terms of volumetric flow rate 0(m/s) and other process variables (e.g. 2, f,L,D,K). b) Using Excel, create a nice plot of pump (m) versus Q (m/s), i.e. the system curve"; set your x-axis scale to range from 0 to 0.028 m/s. c) Now consider the situation where the pump that is used to transport the chloroform between the two reservoirs needs to be replaced. You call up your favourite pump supplier who recommends a Pentair Aurora pump and then sends you the pump performance figure shown below. Sketch the system demand' curve for the fluid flow system on the pump performance curve shown below (NOTE that the same curve is posted as a separate file in the 'Assignment s' folder on Avenue) and then identify which one of the five available impellers should the supplier install if the system must achieve a chloroform flow rate of 0.023 m/s. d) For the impeller that you choose in part d), what would be the actual flow rate (m/s) of chloroform that would be achieved? Propose one strategy that could be used to transition the operating point (also referred to as 'duty point') to achieve the desired chloroform flow rate of 0.023 m/s. 36 60 150 40 8 Head-m 80 60 40 20 a 10 DOC DO bor G.DI DIZ D.04 DIE DDB 100 0034 0.00 NPSNr. DEC 0.004 000 ODI QD12 2018 D.DID Cuscience whypical. For guaranteed to contact Aurora Papar your local distributor. La ci en annan tipiem. Para valores paranteraction contacte a Aurora pedibuidor local Company PENTAR AURORA Nam MCMASTER UNIVERSITY AURORA PUMPS Catalog Aurora Pumps He Vers 4.4 420 MULTI STO SPUT-1000 Curve PC-116800 S21A Speed 3600 rpm PENTAIR AURORA