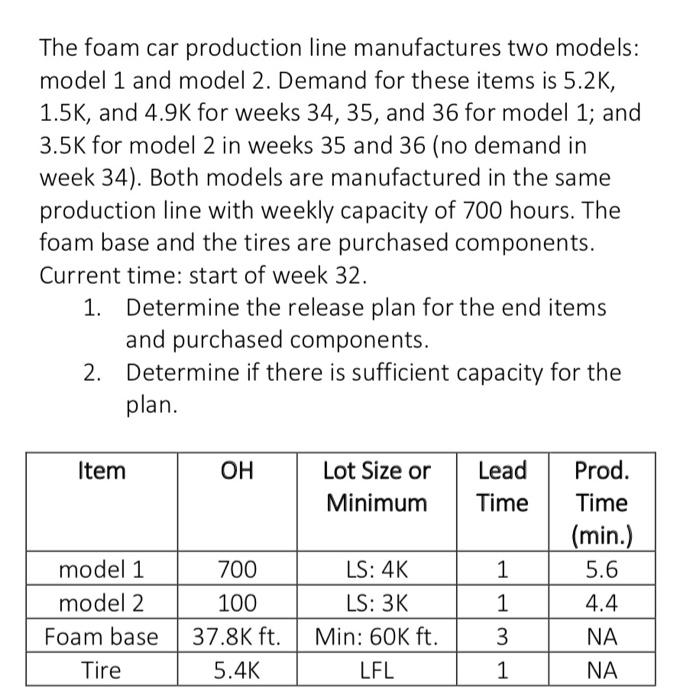

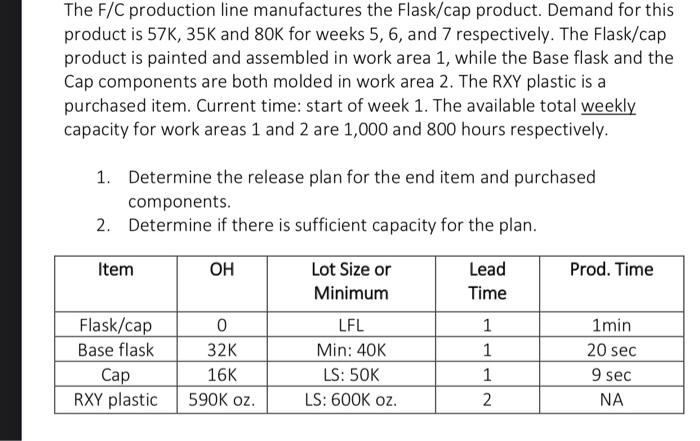

The foam car production line manufactures two models: model 1 and model 2. Demand for these items is 5.2K, 1.5K, and 4.9k for weeks 34, 35, and 36 for model 1; and 3.5K for model 2 in weeks 35 and 36 (no demand in week 34). Both models are manufactured in the same production line with weekly capacity of 700 hours. The foam base and the tires are purchased components. Current time: start of week 32. 1. Determine the release plan for the end items and purchased components. 2. Determine if there is sufficient capacity for the plan. Item OH Lot Size or Minimum Lead Time 1 model 1 model 2 Foam base Tire 700 100 37.8K ft. 5.4K LS: 4K LS: 3K Min: 60K ft. LFL Prod. Time (min.) 5.6 4.4 NA NA 1 3 1 The F/C production line manufactures the Flask/cap product. Demand for this product is 57K, 35K and 80K for weeks 5, 6, and 7 respectively. The Flask/cap product is painted and assembled in work area 1, while the Base flask and the Cap components are both molded in work area 2. The RXY plastic is a purchased item. Current time: start of week 1. The available total weekly capacity for work areas 1 and 2 are 1,000 and 800 hours respectively. 1. Determine the release plan for the end item and purchased components. 2. Determine if there is sufficient capacity for the plan. Item OH Prod. Time Lead Time Flask/cap Base flask Cap RXY plastic 0 32K 16K 590K oz. Lot Size or Minimum LFL Min: 40K LS: 50K LS: 600K oz. 1 1 1 1min 20 sec 9 sec NA 1 N The foam car production line manufactures two models: model 1 and model 2. Demand for these items is 5.2K, 1.5K, and 4.9k for weeks 34, 35, and 36 for model 1; and 3.5K for model 2 in weeks 35 and 36 (no demand in week 34). Both models are manufactured in the same production line with weekly capacity of 700 hours. The foam base and the tires are purchased components. Current time: start of week 32. 1. Determine the release plan for the end items and purchased components. 2. Determine if there is sufficient capacity for the plan. Item OH Lot Size or Minimum Lead Time 1 model 1 model 2 Foam base Tire 700 100 37.8K ft. 5.4K LS: 4K LS: 3K Min: 60K ft. LFL Prod. Time (min.) 5.6 4.4 NA NA 1 3 1 The F/C production line manufactures the Flask/cap product. Demand for this product is 57K, 35K and 80K for weeks 5, 6, and 7 respectively. The Flask/cap product is painted and assembled in work area 1, while the Base flask and the Cap components are both molded in work area 2. The RXY plastic is a purchased item. Current time: start of week 1. The available total weekly capacity for work areas 1 and 2 are 1,000 and 800 hours respectively. 1. Determine the release plan for the end item and purchased components. 2. Determine if there is sufficient capacity for the plan. Item OH Prod. Time Lead Time Flask/cap Base flask Cap RXY plastic 0 32K 16K 590K oz. Lot Size or Minimum LFL Min: 40K LS: 50K LS: 600K oz. 1 1 1 1min 20 sec 9 sec NA 1 N