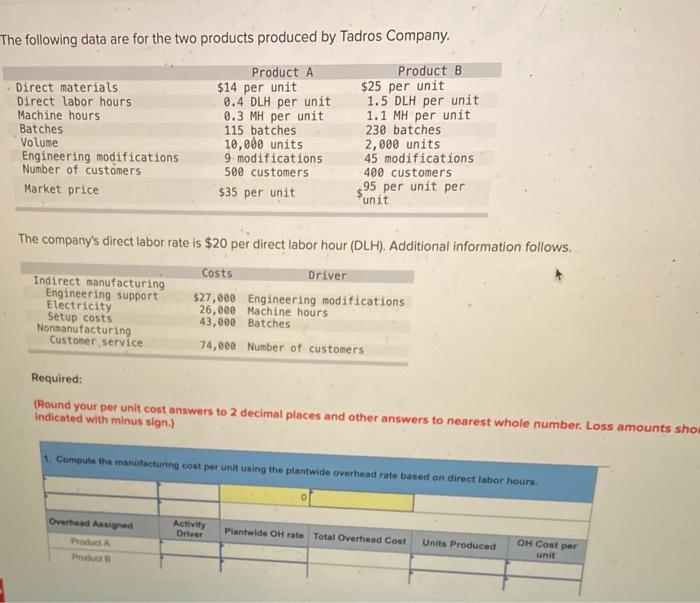

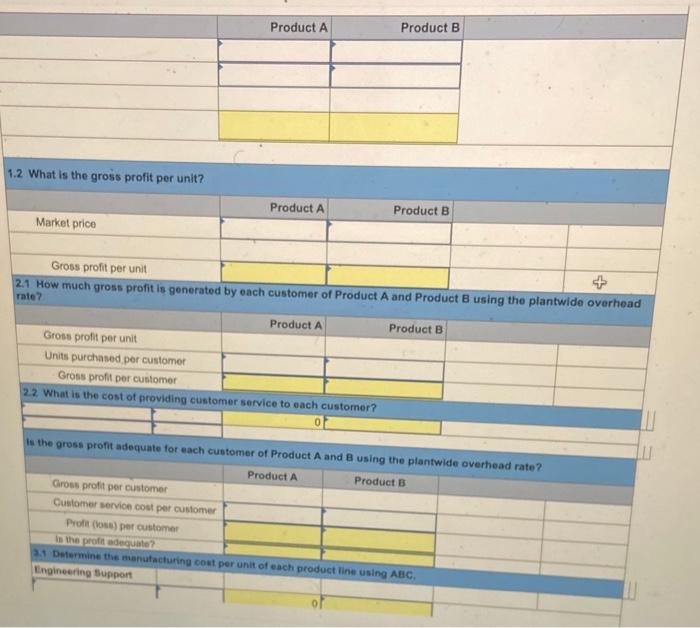

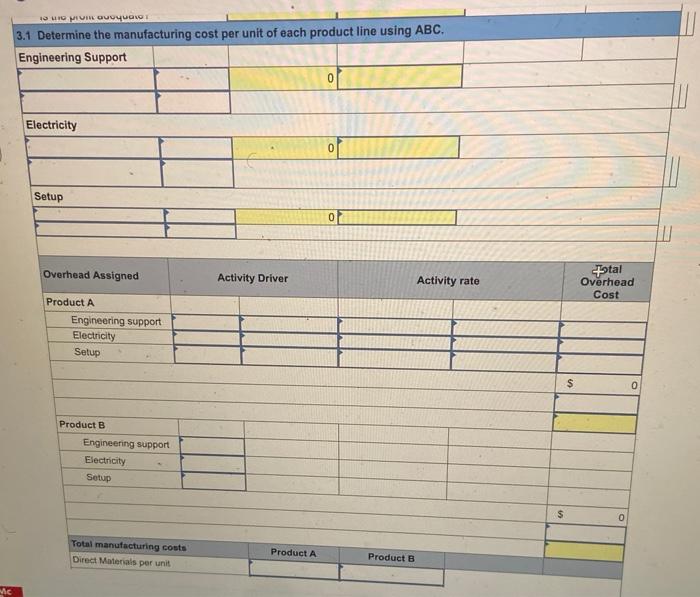

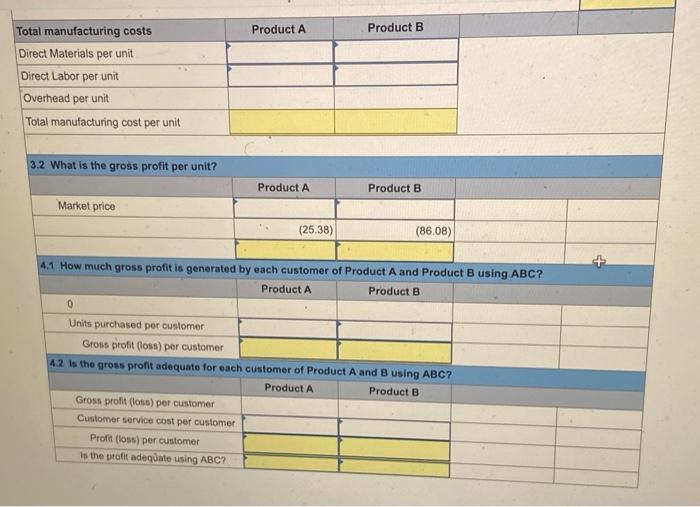

The following data are for the two products produced by Tadros Company. Direct materials Direct labor hours Machine hours Batches Volume Engineering modifications Number of customers Market price Product A $14 per unit 0.4 DLH per unit 0.3 MH per unit 115 batches 10,000 units 9 modifications 500 customers $35 per unit Product B $25 per unit 1.5 DLH per unit 1.1 MH per unit 230 batches 2,000 units 45 modifications 400 customers 95 per unit per Sunit The company's direct labor rate is $20 per direct labor hour (DLH). Additional information follows. Indirect manufacturing Engineering support Electricity Setup costs Nonmanufacturing Customer service Costs Driver $27,000 Engineering modifications 26,880 Machine hours 43,000 Batches 74,880 Number of customers Required: (Round your per unit cost answers to 2 decimal places and other answers to nearest whole number. Loss amounts shou Indicated with minus sign.) 1. Compute the manufacturing cost per unit using the plantwide overhead rate based on direct labor hours Overhead Assigned Activity Driver Plantwide OH rate Total Overhead Cost Units Produced OH Cost per unit Product A Product B 1.2 What is the gross profit per unit? Product A Product B Market price Gross profit per unit 2.1 How much gross profit is generated by each customer of Product A and Product B using the plantwide overhead rate? Product A Product B Gross profit per unit Units purchased per customer Gross profit per customer 22 What is the cost of providing customer service to each customer? Is the gross profit adequate for each customer of Product A and B using the plantwide overhead rate? Product A Product B Gross profiter customer Customer service cost per customer Protons) per customer In the profit adequate? 2.1 Determine the manufacturing cost per unit of each product line using ABC Engineering Support IS U MIUI QUOYUQ 3.1 Determine the manufacturing cost per unit of each product line using ABC. Engineering Support 0 Electricity of Setup 02 Overhead Assigned Activity Driver Activity rate Potal Overhead Cost Product A Engineering support Electricity Setup $ 0 Product B Engineering support Electricity Setup $ 0 Total manufacturing costs Direct Materials per unit Product A Product B MC