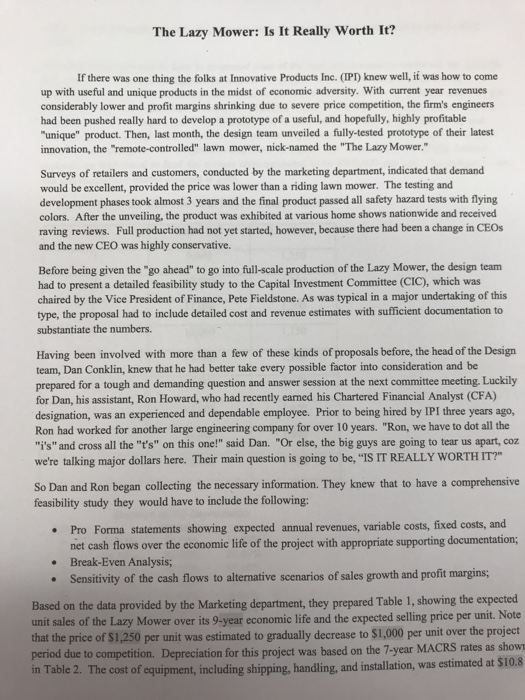

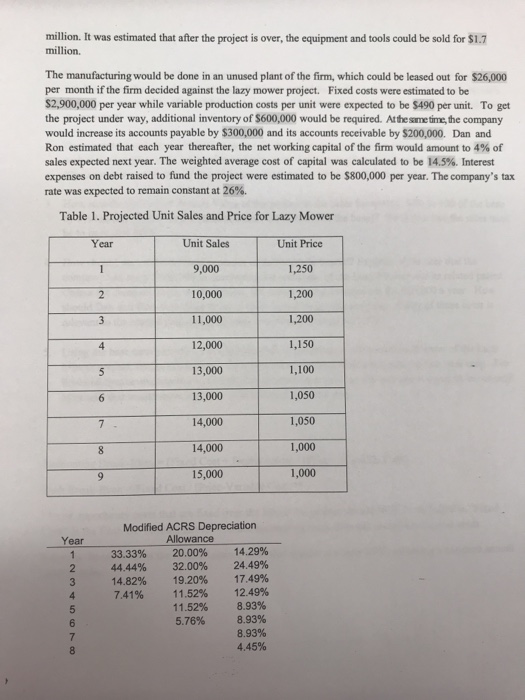

The Lazy Mower: Is It Really Worth It? If there was one thing the folks at Innovative Products Inc. (IPI) knew well, it was how to come up with useful and unique products in the midst of economic adversity. With current year revenues considerably lower and profit margins shrinking due to severe price competition, the firm's engineers had been pushed really hard to develop a prototype of a useful, and hopefully, highly profitable unique" product. Then, last month, the design team unveiled a fully-tested prototype of their latest innovation, the "remote-controlled lawn mower, nick-named the "The Lazy Mower." Surveys of retailers and customers, conducted by the marketing department, indicated that demand would be excellent, provided the price was lower than a riding lawn mower. The testing and development phases took almost 3 years and the final product passed all safety hazard tests with flying colors. After the unveiling, the product was exhibited at various home shows nationwide and received raving reviews. Full production had not yet started, however, because there had been a change in CEOs and the new CEO was highly conservative. Before being given the "go ahead" to go into full-scale production of the Lazy Mower, the design tearm had to present a detailed feasibility study to the Capital Investment Committee (CIC), which was chaired by the Vice President of Finance, Pete Fieldstone. As was typical in a major undertaking of this type, the proposal had to include detailed cost and revenue estimates with sufficient documentation to substantiate the numbers. Having been involved with more than a few of these kinds of proposals before, the head of the Design team, Dan Conklin, knew that he had better take every possible factor into consideration and be prepared for a tough and demanding question and answer session at the next committee meeting. Luckily for Dan, his assistant, Ron Howard, who had recently earned his Chartered Financial Analyst (CFA) designation, was an experienced and dependable employee. Prior to being hired by IPI three years ago, Ron had worked for another large engineering company for over 10 years. "Ron, we have to dot all the "i's" and cross all the "t's" on this one!" said Dan. "Or else, the big guys are going to tear us apart, coz we're talking major dollars here. Their main question is going to be, "IS IT REALLY WORTH IT?" So Dan and Ron began collecting the necessary information. They knew that to have a comprehensive feasibility study they would have to include the following: Pro Forma statements showing expected annual revenues, variable costs, fixed costs, and net cash flows over the economic life of the project with appropriate supporting documentation; . Break-Even Analysis; Sensitivity of the cash flows to alternative scenarios of sales growth and profit margins; Based on the data provided by the Marketing department, they prepared Table 1, showing the expected unit sales of the Lazy Mower over its 9-year economic life and the expected selling price per unit. Note that the price of $1,250 per unit was estimated to gradually decrease to $1,000 per unit over the project period due to competition. Depreciation for this project was based on the 7-year MACRS rates as shown cost of equipment, including shipping, handling, and installation, was estimated at $10.8 The Lazy Mower: Is It Really Worth It? If there was one thing the folks at Innovative Products Inc. (IPI) knew well, it was how to come up with useful and unique products in the midst of economic adversity. With current year revenues considerably lower and profit margins shrinking due to severe price competition, the firm's engineers had been pushed really hard to develop a prototype of a useful, and hopefully, highly profitable unique" product. Then, last month, the design team unveiled a fully-tested prototype of their latest innovation, the "remote-controlled lawn mower, nick-named the "The Lazy Mower." Surveys of retailers and customers, conducted by the marketing department, indicated that demand would be excellent, provided the price was lower than a riding lawn mower. The testing and development phases took almost 3 years and the final product passed all safety hazard tests with flying colors. After the unveiling, the product was exhibited at various home shows nationwide and received raving reviews. Full production had not yet started, however, because there had been a change in CEOs and the new CEO was highly conservative. Before being given the "go ahead" to go into full-scale production of the Lazy Mower, the design tearm had to present a detailed feasibility study to the Capital Investment Committee (CIC), which was chaired by the Vice President of Finance, Pete Fieldstone. As was typical in a major undertaking of this type, the proposal had to include detailed cost and revenue estimates with sufficient documentation to substantiate the numbers. Having been involved with more than a few of these kinds of proposals before, the head of the Design team, Dan Conklin, knew that he had better take every possible factor into consideration and be prepared for a tough and demanding question and answer session at the next committee meeting. Luckily for Dan, his assistant, Ron Howard, who had recently earned his Chartered Financial Analyst (CFA) designation, was an experienced and dependable employee. Prior to being hired by IPI three years ago, Ron had worked for another large engineering company for over 10 years. "Ron, we have to dot all the "i's" and cross all the "t's" on this one!" said Dan. "Or else, the big guys are going to tear us apart, coz we're talking major dollars here. Their main question is going to be, "IS IT REALLY WORTH IT?" So Dan and Ron began collecting the necessary information. They knew that to have a comprehensive feasibility study they would have to include the following: Pro Forma statements showing expected annual revenues, variable costs, fixed costs, and net cash flows over the economic life of the project with appropriate supporting documentation; . Break-Even Analysis; Sensitivity of the cash flows to alternative scenarios of sales growth and profit margins; Based on the data provided by the Marketing department, they prepared Table 1, showing the expected unit sales of the Lazy Mower over its 9-year economic life and the expected selling price per unit. Note that the price of $1,250 per unit was estimated to gradually decrease to $1,000 per unit over the project period due to competition. Depreciation for this project was based on the 7-year MACRS rates as shown cost of equipment, including shipping, handling, and installation, was estimated at $10.8