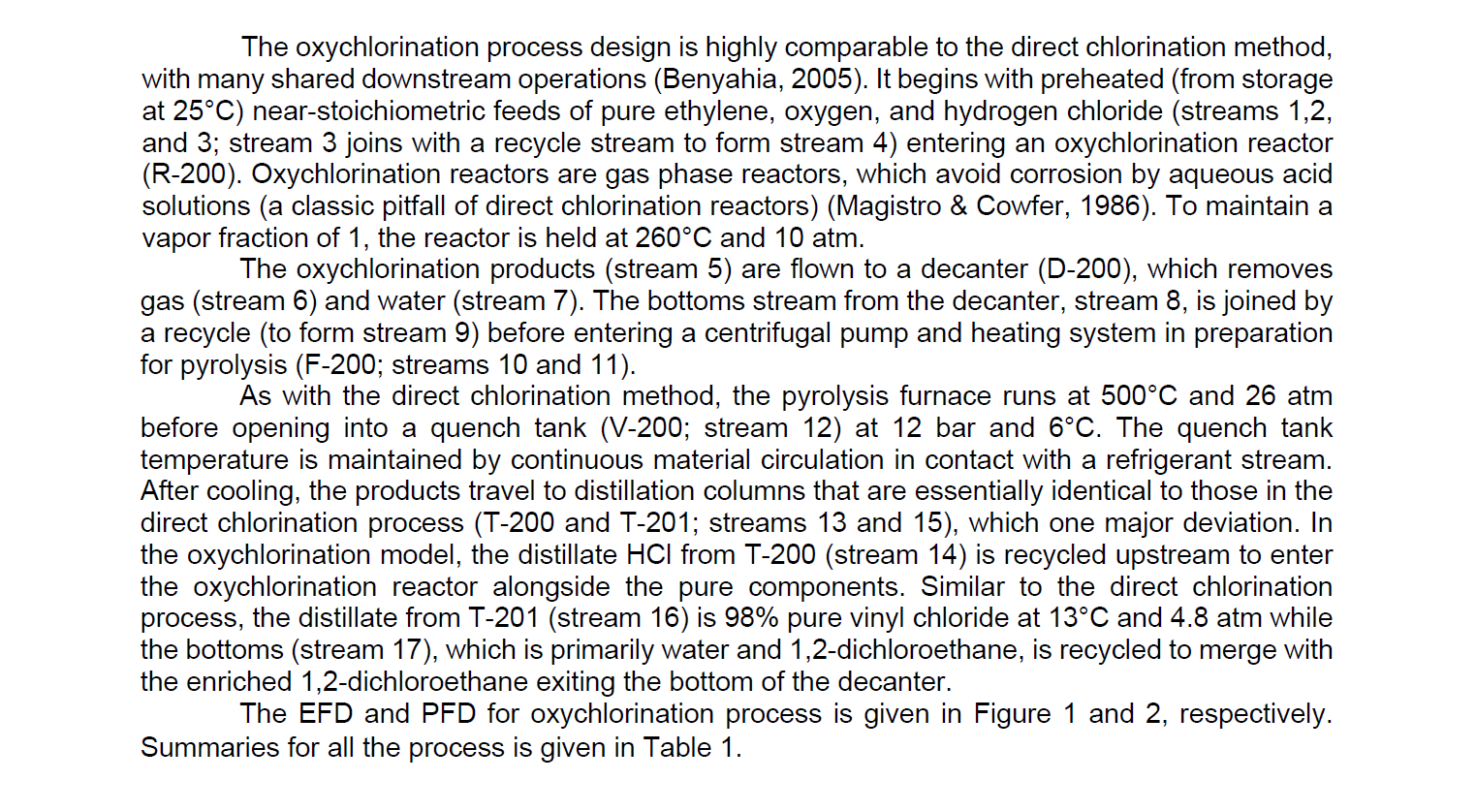

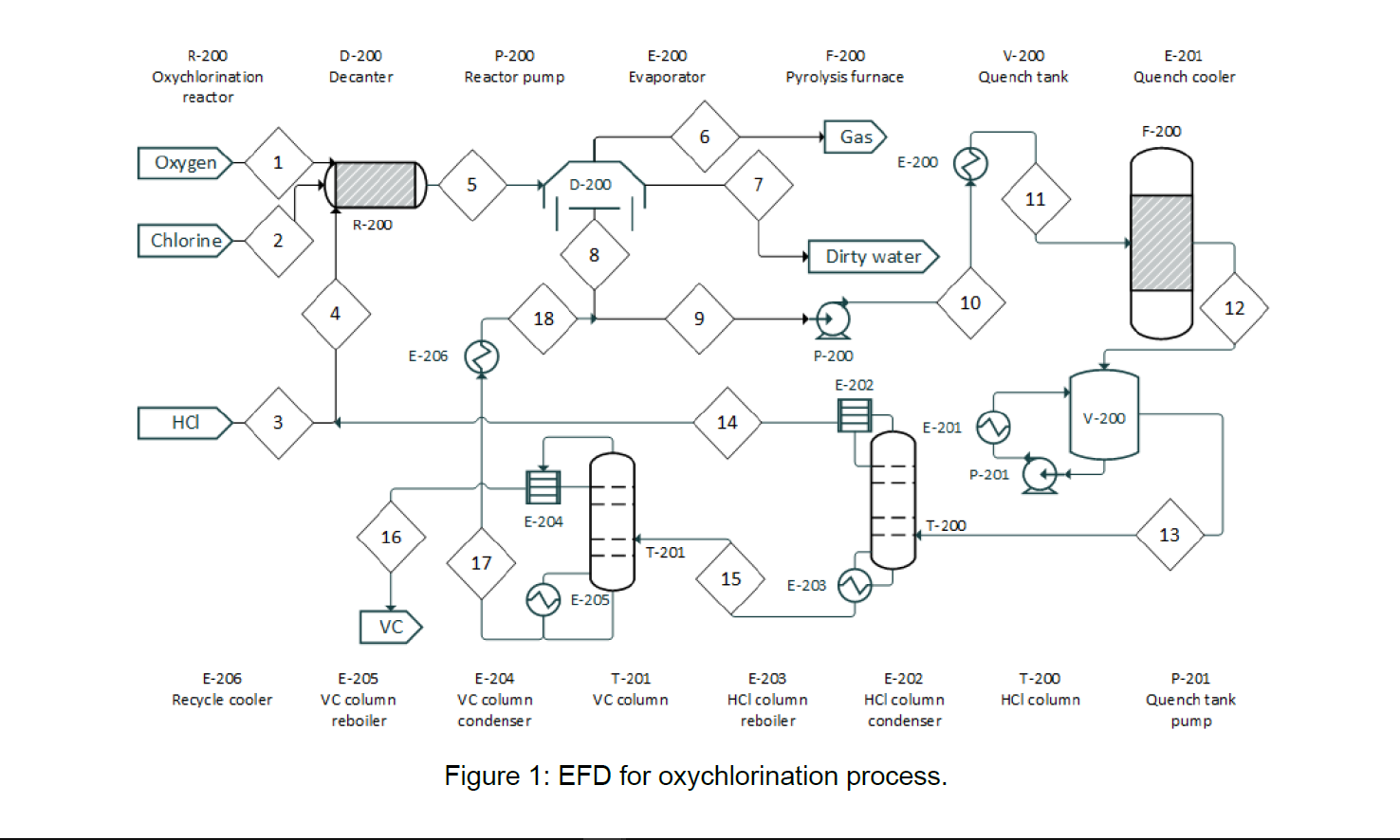

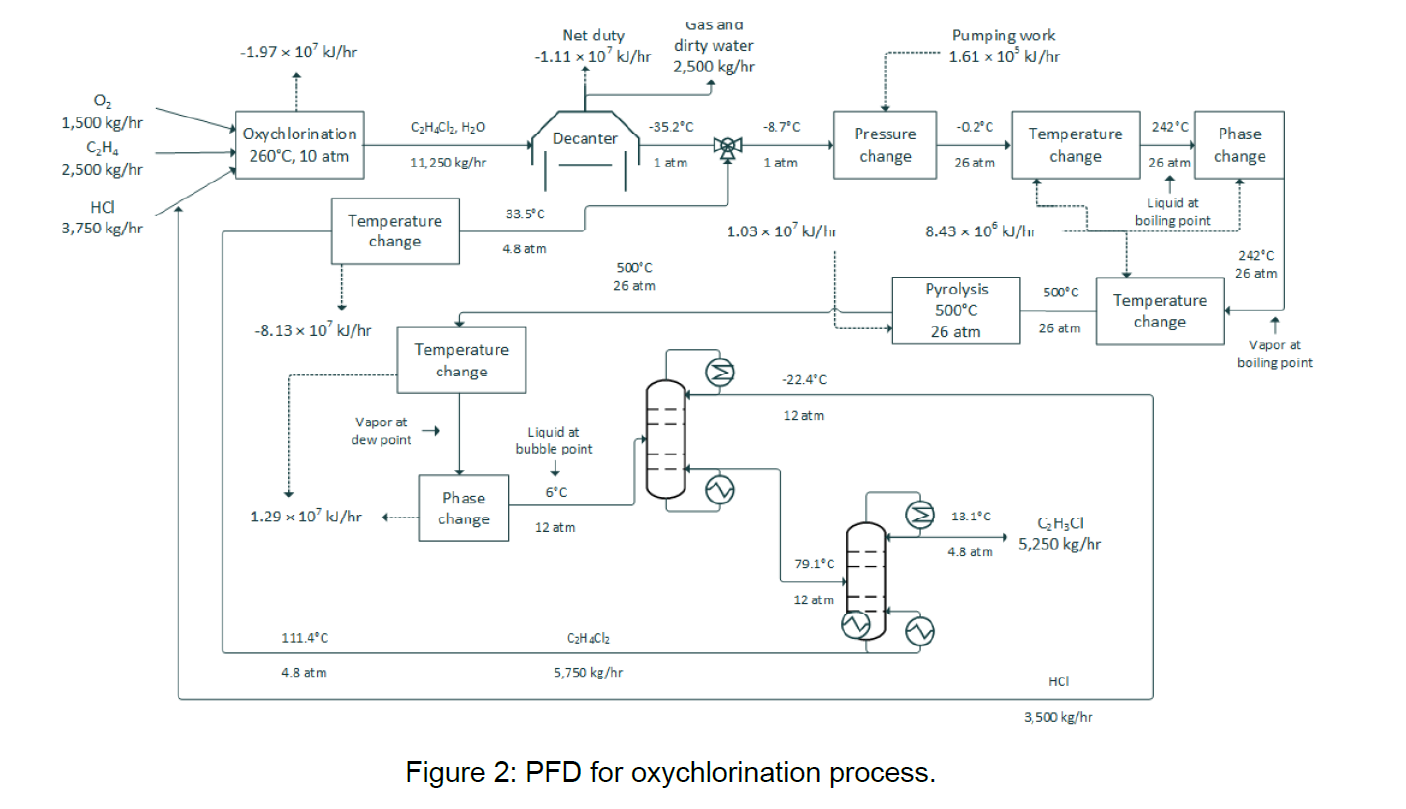

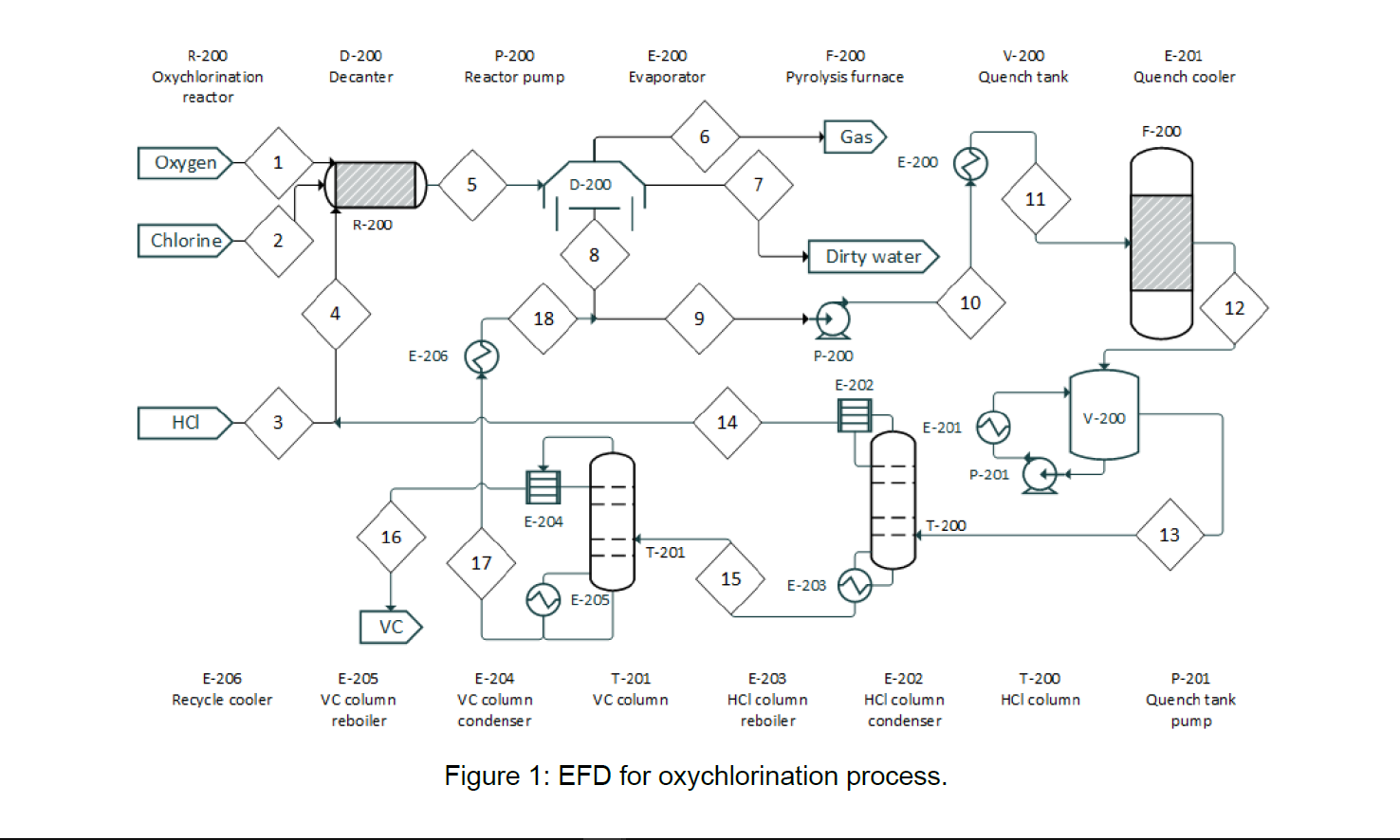

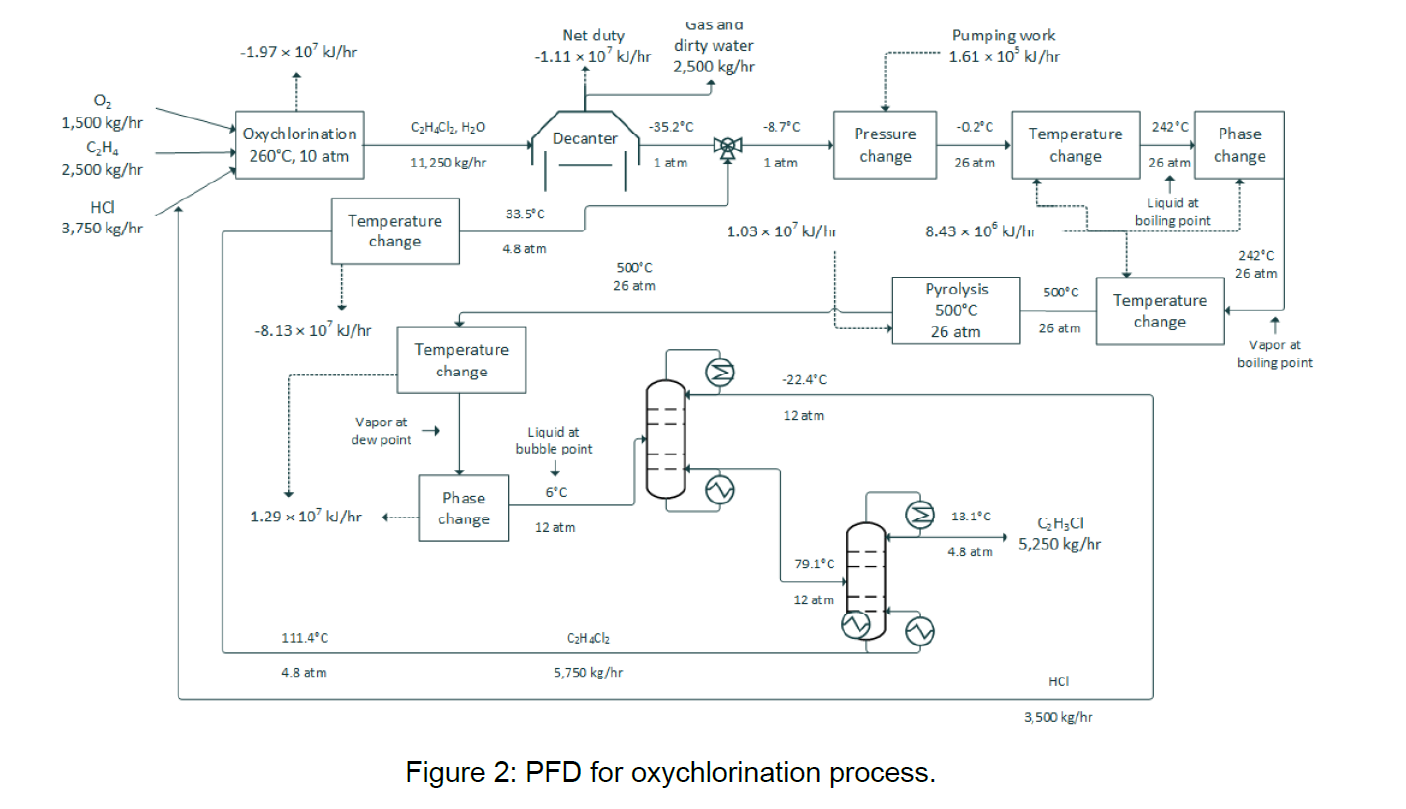

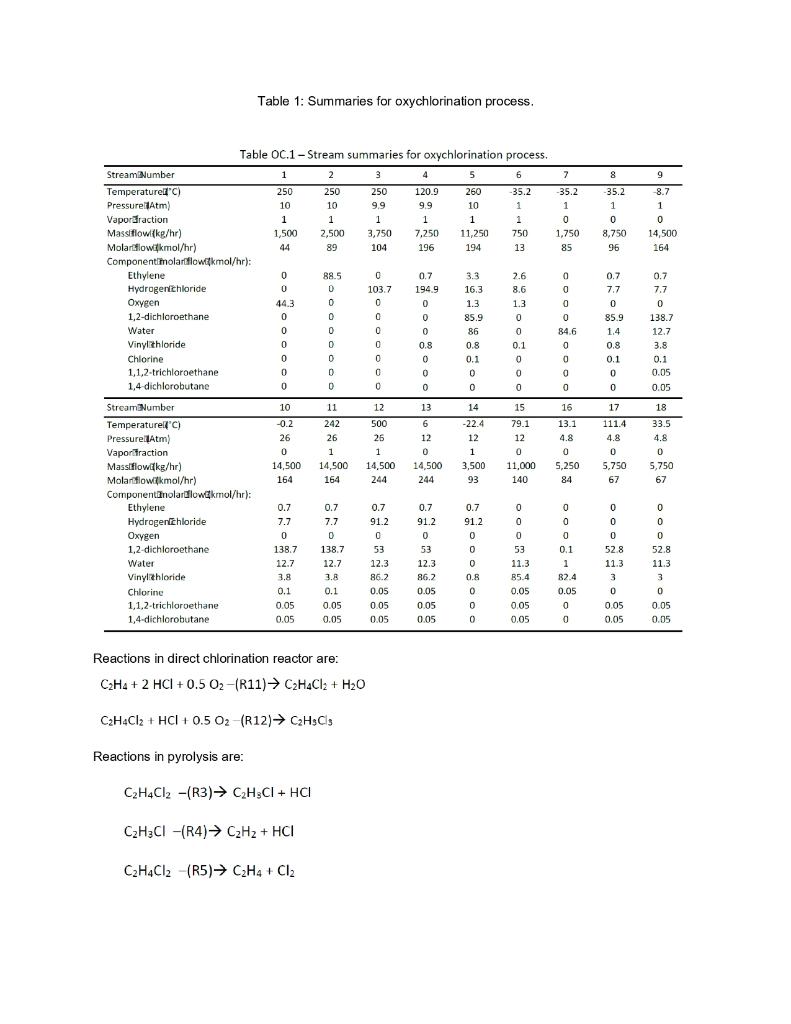

The oxychlorination process design is highly comparable to the direct chlorination method, with many shared downstream operations (Benyahia, 2005). It begins with preheated (from storage at 25C) near-stoichiometric feeds of pure ethylene, oxygen, and hydrogen chloride (streams 1,2, and 3; stream 3 joins with a recycle stream to form stream 4) entering an oxychlorination reactor (R-200). Oxychlorination reactors are gas phase reactors, which avoid corrosion by aqueous acid solutions (a classic pitfall of direct chlorination reactors) (Magistro & Cowfer, 1986). To maintain a vapor fraction of 1, the reactor is held at 260C and 10 atm. The oxychlorination products (stream 5) are flown to a decanter (D-200), which removes gas (stream 6) and water (stream 7). The bottoms stream from the decanter, stream 8, is joined by a recycle (to form stream 9) before entering a centrifugal pump and heating system in preparation for pyrolysis (F-200; streams 10 and 11). As with the direct chlorination method, the pyrolysis furnace runs at 500C and 26 atm before opening into a quench tank (V-200; stream 12) at 12 bar and 6C. The quench tank temperature is maintained by continuous material circulation in contact with a refrigerant stream. After cooling, the products travel to distillation columns that are essentially identical to those in the direct chlorination process (T-200 and T-201; streams 13 and 15), which one major deviation. In the oxychlorination model, the distillate HCl from T-200 (stream 14) is recycled upstream to enter the oxychlorination reactor alongside the pure components. Similar to the direct chlorination process, the distillate from T-201 (stream 16) is 98% pure vinyl chloride at 13C and 4.8 atm while the bottoms (stream 17), which is primarily water and 1,2-dichloroethane, is recycled to merge with the enriched 1,2-dichloroethane exiting the bottom of the decanter. The EFD and PFD for oxychlorination process is given in Figure 1 and 2, respectively. Summaries for all the process is given in Table 1. F-200 R-200 Oxychlorination reactor D-200 Decanter P-200 Reactor pump E-200 Evaporator V-200 Quench tank E-201 Quench cooler Pyrolysis furnace 6 Gas F-200 Oxygen 1 E-200 5 D-200 7 11 R-200 Chlorine 2 8 Dirty water 10 4 12 18 9 E-206 P-200 E-202 3 14 V-200 E-201 11 P-201 1 E-204 T-200 16 13 II T-201 17 15 E-203 E-205 VC E-206 Recycle cooler E-205 VC column reboiler E-204 VC column condenser T-201 VC column E-203 HCl column reboiler E-202 HCl column condenser T-200 HCl column P-201 Quench tank pump Figure 1: EFD for oxychlorination process. -1.97 x 107kJ/hr Net duty -1.11 x 10 kJ/hr Gas and dirty water 2,500 kg/hr Pumping work 1.61 x 10 kJ/hr CzH4Cl2, H2O -35.2C -8.7C -0.2C O2 1,500 kg/hr CH 2,500 kg/hr Oxychlorination 260C, 10 atm Decanter Pressure change Temperature change 11,250 kg/hr 1 atm 1 atm 26 atm 242C Phase 26 atm change 1 Liquid at boiling point 3,750 kg/hr 33.5C Temperature change 1.03