Question

The Parker Corporation produces and sells a machine for tending golf course greens. The patented device trims the grass, aerates the turf, and injects a

The Parker Corporation produces and sells a machine for tending golf course greens. The patented device trims the grass, aerates the turf, and injects a metered amount of nitrogen into the soil. Machines are marketed through the Taylor Golf Course Supply Company, under the Parker Companys own original equipment brand, and, recently, through a lawn and garden supply house (Brown Thumb), which serves both commercial and consumer accounts. Addition of the lawn and garden outlet and requests to add a 3-HP version have called into question the production planning and control process for the machines.

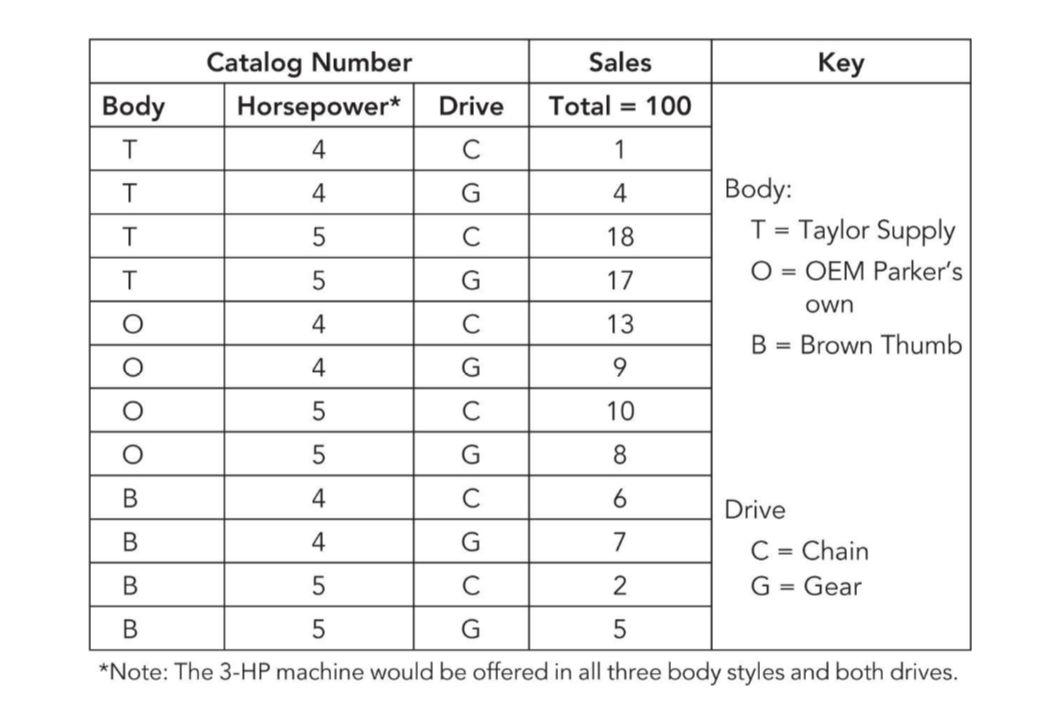

EXHIBIT A Last Years Sales by Catalog Number \

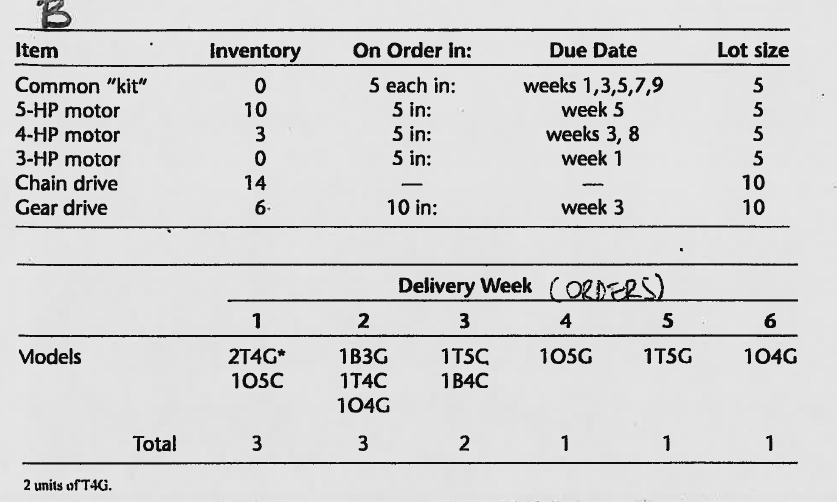

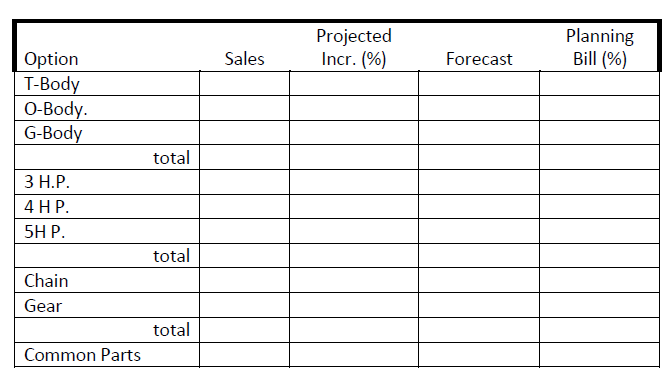

Forecasting the products to be produced is difficult. There are now two drive mechanisms (chain and gear), three different body styles (one for each outlet), and two engine sizes (4- and 5-HP). This gives a total of 12 end items, all of which had some demand. (See Exhibit A.) The 3-HP motor would add six more end items. Forecasting demand for these new items would add to the difficulty of forecasting demand. Lead times for some of the castings (gear or chain) and for 5-HP motors have increased to the extent that it is not possible to wait until firm orders are received for the end items before the castings and motors have to be ordered. In addition, the firms business is growing; it anticipates selling about 120 units next year. Consequently, the production manager has arranged to purchase enough material for 10 units per month. There is plenty of capacity for the small amount of parts fabrication required, but assembly capacity must be carefully planned. The current plan calls for assembly capacity of 10 units per month. With regard to the specific issue of forecasting, the marketing manager summarized the data on the sales of each end item over the past year. (See Exhibit A.) He felt that a 20 percent growth in total volume was about right and that 3-HP machines will perhaps account for half that growth. Of course, once the forecasts were made, the production manager had to determine which motors and castings (gear or chain) to order. Each machine was made up of many common parts, but the motors, chain or gear drive subassemblies, and bodies were different (though interchangeable).

a. Suggest an improved method of forecasting demand for the firms products.

b. As the production manager contemplated the difficulty of forecasting demand for the firms products and determining exactly what to schedule into final assembly, two customers called. The first, from Taylor, wanted to know when the company could deliver a model T3G; the second wanted as early delivery as possible of one of Parkers own machines, an O4C. The Taylor representative said he felt that the three-horsepower models might really take off.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started