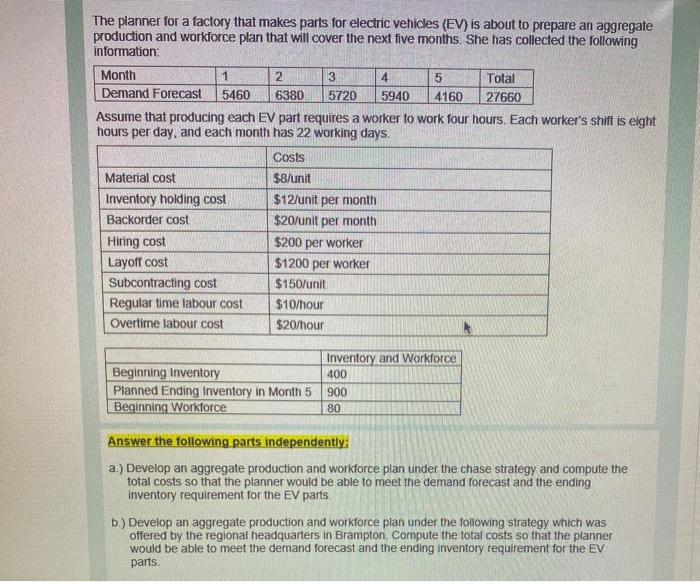

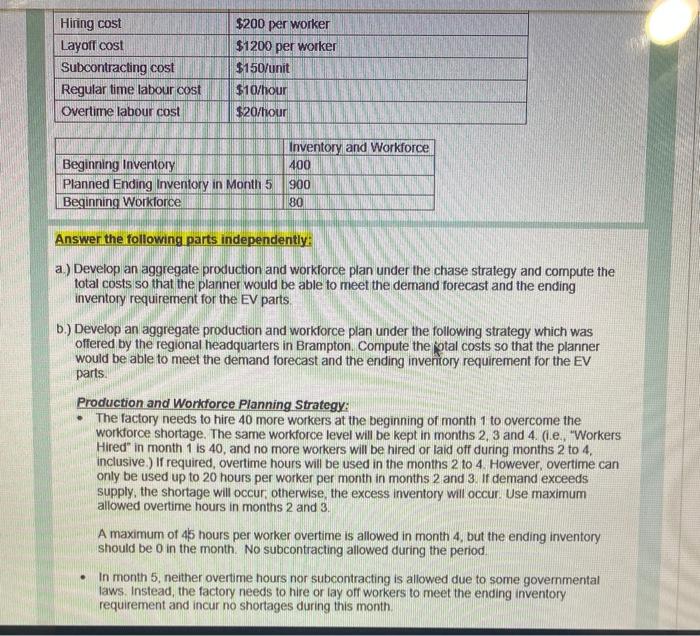

The planner for a factory that makes parts for electric vehicles (EV) is about to prepare an aggregate production and workforce plan that will cover the next five months. She has collected the following information: Month 1 3 4 5 Total Demand Forecast 5460 6380 5720 5940 4160 27660 Assume that producing each EV part requires a worker to work four hours. Each worker's shift is eight hours per day, and each month has 22 working days. Material cost Inventory holding cost Backorder cost Hiring cost Layoff cost Subcontracting cost Regular time labour cost Overtime labour cost Costs $8/unit $12/unit per month $20/unit per month $200 per worker $1200 per worker $150/unit $10/hour $20/hour Beginning Inventory Planned Ending Inventory in Month 5 Beginning Workforce Inventory and Workforce 400 900 80 Answer the following parts independently: a) Develop an aggregate production and workforce plan under the chase strategy and compute the total costs so that the planner would be able to meet the demand forecast and the ending inventory requirement for the EV parts b.) Develop an aggregate production and workforce plan under the following strategy which was offered by the regional headquarters in Brampton Compute the total costs so that the planner would be able to meet the demand forecast and the ending inventory requirement for the EV parts Hiring cost Layoff cost Subcontracting cost Regular time labour cost Overtime labour cost $200 per worker $1200 per worker $150/unit $10/hour $20/hour Beginning Inventory Planned Ending Inventory in Month 5 Beginning Workforce Inventory and Workforce 400 900 80 Answer the following parts independently a) Develop an aggregate production and workforce plan under the chase strategy and compute the total costs so that the planner would be able to meet the demand forecast and the ending inventory requirement for the EV parts b.) Develop an aggregate production and workforce plan under the following strategy which was offered by the regional headquarters in Brampton, Compute the tal costs so that the planner would be able to meet the demand forecast and the ending inventory requirement for the EV parts Production and Workforce Planning Strategy: The factory needs to hire 40 more workers at the beginning of month 1 to overcome the workforce shortage. The same workforce level will be kept in months 2.3 and 4. (.e., "Workers Hired" in month 1 is 40, and no more workers will be hired or laid off during months 2 to 4, inclusive ) If required, overtime hours will be used in the months 2 to 4. However, overtime can only be used up to 20 hours per worker per month in months 2 and 3. If demand exceeds supply, the shortage will occur otherwise, the excess inventory will occur. Use maximum allowed overtime hours in months 2 and 3. A maximum of 45 hours per worker overtime is allowed in month 4, but the ending inventory should be o in the month. No subcontracting allowed during the period . In month 5, neither overtime hours nor subcontracting is allowed due to some governmental laws. Instead, the factory needs to hire or lay off workers to meet the ending inventory requirement and incur no shortages during this month The planner for a factory that makes parts for electric vehicles (EV) is about to prepare an aggregate production and workforce plan that will cover the next five months. She has collected the following information: Month 1 3 4 5 Total Demand Forecast 5460 6380 5720 5940 4160 27660 Assume that producing each EV part requires a worker to work four hours. Each worker's shift is eight hours per day, and each month has 22 working days. Material cost Inventory holding cost Backorder cost Hiring cost Layoff cost Subcontracting cost Regular time labour cost Overtime labour cost Costs $8/unit $12/unit per month $20/unit per month $200 per worker $1200 per worker $150/unit $10/hour $20/hour Beginning Inventory Planned Ending Inventory in Month 5 Beginning Workforce Inventory and Workforce 400 900 80 Answer the following parts independently: a) Develop an aggregate production and workforce plan under the chase strategy and compute the total costs so that the planner would be able to meet the demand forecast and the ending inventory requirement for the EV parts b.) Develop an aggregate production and workforce plan under the following strategy which was offered by the regional headquarters in Brampton Compute the total costs so that the planner would be able to meet the demand forecast and the ending inventory requirement for the EV parts Hiring cost Layoff cost Subcontracting cost Regular time labour cost Overtime labour cost $200 per worker $1200 per worker $150/unit $10/hour $20/hour Beginning Inventory Planned Ending Inventory in Month 5 Beginning Workforce Inventory and Workforce 400 900 80 Answer the following parts independently a) Develop an aggregate production and workforce plan under the chase strategy and compute the total costs so that the planner would be able to meet the demand forecast and the ending inventory requirement for the EV parts b.) Develop an aggregate production and workforce plan under the following strategy which was offered by the regional headquarters in Brampton, Compute the tal costs so that the planner would be able to meet the demand forecast and the ending inventory requirement for the EV parts Production and Workforce Planning Strategy: The factory needs to hire 40 more workers at the beginning of month 1 to overcome the workforce shortage. The same workforce level will be kept in months 2.3 and 4. (.e., "Workers Hired" in month 1 is 40, and no more workers will be hired or laid off during months 2 to 4, inclusive ) If required, overtime hours will be used in the months 2 to 4. However, overtime can only be used up to 20 hours per worker per month in months 2 and 3. If demand exceeds supply, the shortage will occur otherwise, the excess inventory will occur. Use maximum allowed overtime hours in months 2 and 3. A maximum of 45 hours per worker overtime is allowed in month 4, but the ending inventory should be o in the month. No subcontracting allowed during the period . In month 5, neither overtime hours nor subcontracting is allowed due to some governmental laws. Instead, the factory needs to hire or lay off workers to meet the ending inventory requirement and incur no shortages during this month