Answered step by step

Verified Expert Solution

Question

1 Approved Answer

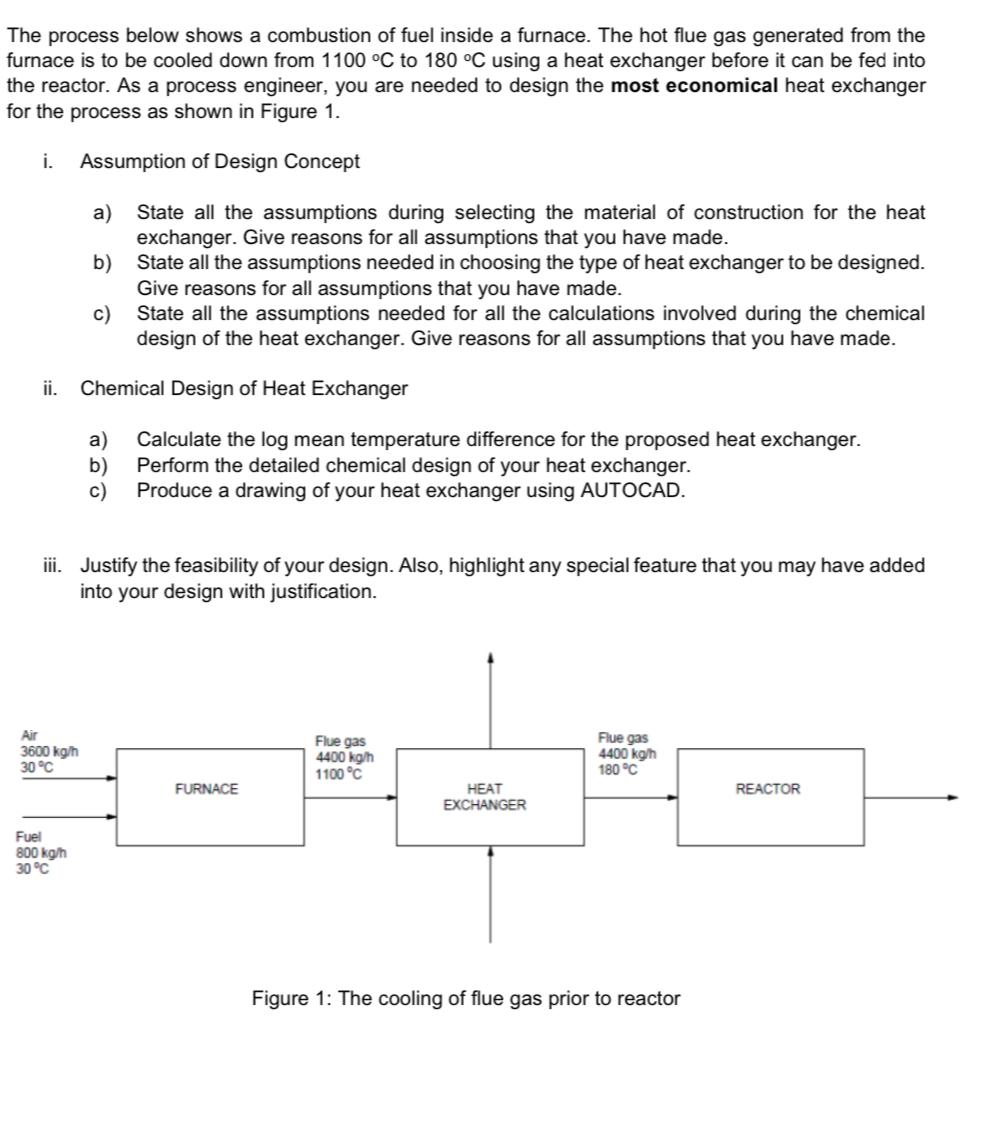

The process below shows a combustion of fuel inside a furnace. The hot flue gas generated from the furnace is to be cooled down

The process below shows a combustion of fuel inside a furnace. The hot flue gas generated from the furnace is to be cooled down from 1100 C to 180 C using a heat exchanger before it can be fed into the reactor. As a process engineer, you are needed to design the most economical heat exchanger for the process as shown in Figure 1. i. Assumption of Design Concept State all the assumptions during selecting the material of construction for the heat exchanger. Give reasons for all assumptions that you have made. State all the assumptions needed in choosing the type of heat exchanger to be designed. Give reasons for all assumptions that you have made. State all the assumptions needed for all the calculations involved during the chemical design of the heat exchanger. Give reasons for all assumptions that you have made. ii. Chemical Design of Heat Exchanger a) b) c) Air 3600 kg/h 30 C Fuel 800 kg/h 30 C Calculate the log mean temperature difference for the proposed heat exchanger. Perform the detailed chemical design of your heat exchanger. iii. Justify the feasibility of your design. Also, highlight any special feature that you may have added into your design with justification. a) b) c) Produce a drawing of your heat exchanger using AUTOCAD. Flue gas 4400 kg/h 1100 C 09 FURNACE HEAT EXCHANGER Flue gas 4400 kg/h 180 C Figure 1: The cooling of flue gas prior to reactor REACTOR

Step by Step Solution

★★★★★

3.47 Rating (154 Votes )

There are 3 Steps involved in it

Step: 1

Solution...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started