Question

The production of the shoes depends on the number of order per bulk of customer of OTTO Manufacturing. Everyday, there is a set of desired

The production of the shoes depends on the number of order per bulk of customer of OTTO Manufacturing. Everyday, there is a set of desired output that each production line needs to meet. As per the interview from the operation's vice president manager, Mr. John Cruz, the average demand of customer increases up to 6,000 pair of shoes per month with a daily desired output or quota of 300 pairs of shoes. As of now, the company is able to produce the 239 pairs. This problem also results to opportunity loss of P14,640 per day or P 3,513,600 annually.

Question: What do you think would be the best costing system that the manager could apply in this case? Explain your answer. What are the advantages and disadvantages of the costing system that you chose?

Existing Operation

Process

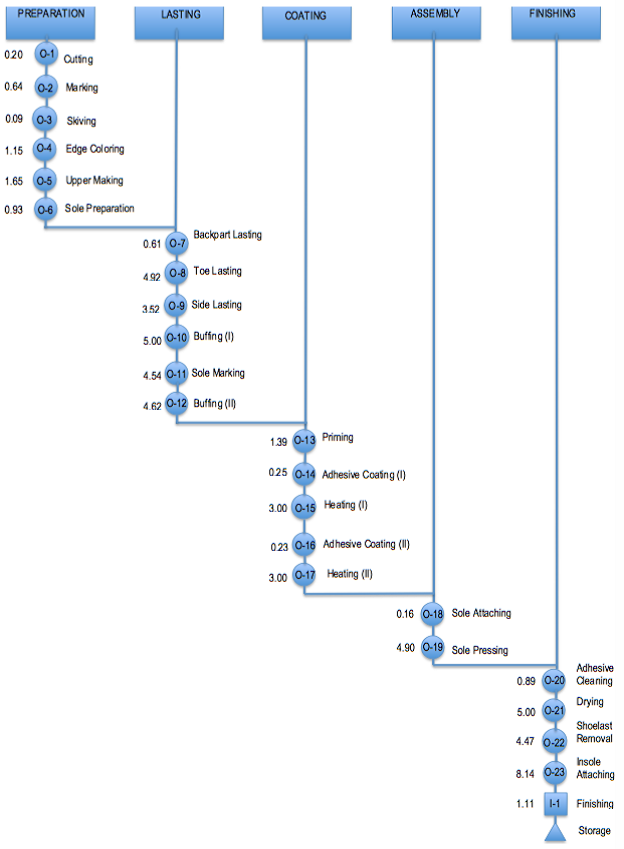

PREPARATION 020 0-1 Cutting 0.64 0-2 Marking 0.09 0-3 Skiving 1.15 0-4 Edge Coloring LASTING COATING ASSEMBLY FINISHING 1.65 0-5 Upper Making 0.93 0-6 Sole Preparation Backpart Lasting 0.61 O-7 4.92 0-8 Toe Lasting 3.52 0-9 Side Lasting 5.00 0-10 Buffing (1) 4.54 0-11 Sole Marking 4.62 0-12 Buffing (II) 1.39 0-13 Priming 025 0-14 Adhesive Coating (1) 3.00 0-15 Heating (1) 0.23 0-16 Adhesive Coating (II) 3.00 O-17 Heating (1) 0.16 0-18 Sole Attaching 4.90 0-19 Sole Pressing Adhesive 0.89 0-20 Cleaning Drying 5.00 0-21 Shoelast 4.47 0-22 Removal Insole 8.14 0-23 Attaching 1.11 1-1 Finishing Storage

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started