Answered step by step

Verified Expert Solution

Question

1 Approved Answer

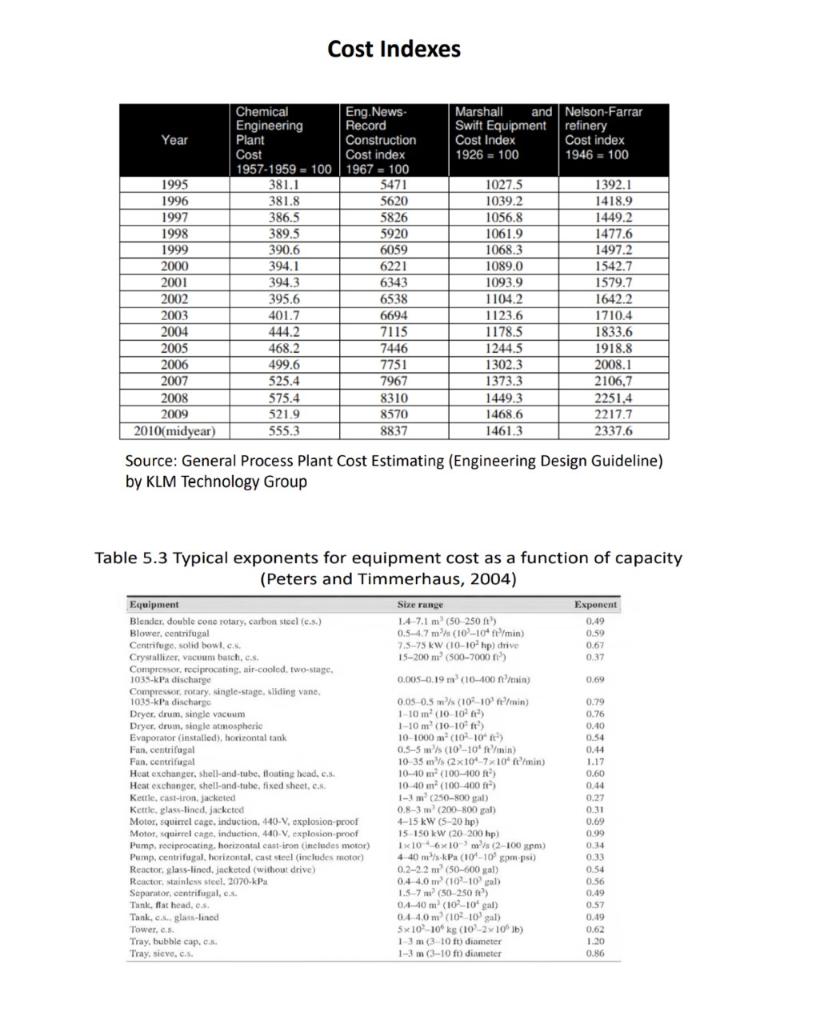

The purchase cost of 0.8m 3 , glass-lined jacketed reactor (without drive) was OMR 5500 in the year 2000. Using the Marshall And Swift Equipment

- The purchase cost of 0.8m3, glass-lined jacketed reactor (without drive) was OMR 5500 in the year 2000.

- Using the Marshall And Swift Equipment cost index, estimate the cost of the same equipment in the year 2005 (2 marks)

- Estimate the cost of similar reactor but with the capacity of 2m3 in the year 2009, based on Marshall And Swift Equipment cost index. (Base your calculation on year 2000) (2 marks

Hint: use the tables below. Leave approximation at 3 decimal places.

Cost Indexes Year Marshall and Nelson-Farrar Swift Equipment refinery Cost Index Cost index 1926 = 100 1946 = 100 1027.5 1039.2 1056.8 1061.9 1995 1996 1997 1998 1000 1999 2000 2001 2002 2009 2003 2004 2004 Sod 2005 2006 2007 2008 2009 2010(midyear) Chemical Eng. News- Engineering Record Plant Construction Cost Cost index 1957-1959 - 100 1967 - 100 381.1 5471 381.8 5620 386.5 5996 5826 389.5 5000 5920 2005 390.6 6059 204 394.1 6221 394.3 623 6343 22 395.6 6538 401.7 6694 444.2 7115 468.2 7446 100 40 499.6 7751 525.4 7967 575.4 8310 521.9 8570 555.3 8837 1069 1068.3 1089.0 1093.9 1104 1104.2 1123.6 1190 1178.5 1244.5 1302.3 1373.3 1449.3 14686 1461.3 1392.1 1418.9 1449.2 14970 1477.6 1402 1497.2 1549 1542.7 1579.7 1642.2 17104 1833.6 1918.8 0. 2008.1 2106,7 2251,4 2217.7 2337.6 Source: General Process Plant Cost Estimating (Engineering Design Guideline) by KLM Technology Group 0.54 Table 5.3 Typical exponents for equipment cost as a function of capacity (Peters and Timmerhaus, 2004) Equipment Ste range Exponent Blender, double cone rotary, carbon steel (..) 1.4 7.1 m (50250) 0.49 Blower, centrifugal 0.5 4.7m (10.-10 1/min) 0.50 Centrifuge, solid bowl.c. 7.5-75 kW (0-10 hp) drive 0.67 Crystalliner, Vacuum burch, 15-200 m (500-7000) 037 Compressor, reciprocating, air-cooled, two-stage 1035-KP discharge 0.005-0.19 (10-400 /min) 0.69 Compresor rotary single-stage, widing vane, 1015 KP discharge 0.05-0.5 (107 10 min) 0.79 Dryer, drum, single vacuum 1-10 m (1010) 0.76 Deyer, drum, single atmospheric 1-10 m (10-10-ft) 0.40 Evaporator installed), bizontal tank 10-1000 m ( 10 ) Fan, centrifugal 0,5-5' (10-10 ft/min) 0.44 Fun, centrifugal 10-35mx101 710 min) 1.17 Heat exchanger, shell-and-tube, touting head. e. 10-10 (100-100) 0.60 Heat exchanger, shell-and-tube, fixed sheet, 10-40 m (100-4001) 0.44 Kettle, cast-iron, jacketed - (250-800 l 0.27 Ketic glass-lined, jacketed 0.8-3 m (200-800 gal) 0.31 Motor, squirrel cage, induction 440-V, explosion-proof 4-15 kW (5-20 hp) 0.69 Motor quicl caps, induction 440V, explosion proof 15 150 kW (20 200 hp) 009 Pump. reciprocating, horizontal cast-iron (includes motor) 1x106x102-100 pm 014 Pump, centrifugal, horizontal, cast steel (includes motor) 4.40 kPa (101-10 psi) 0.33 Reactor, glass-lined, jacketed (without drive) 0.2-12 m (50-600gal) 0.54 Reactor stainless steel 3070 kPa 04-4.0 (102-10 rah 0.56 Separator centrifugale 1.5-7 (50-250) 0.49 Thinkflat head, 04-40 m (10210gal) 0.57 Think glove-lined 04.40 (102 10) 0.19 Tower, 5x10 10 kg (10210) 0.62 Tray, bubble cap, 13m (3-10 ft) diameter 1.230 Tray, sieve, 1-3 m (3-10 fn dimeter 0.86Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started