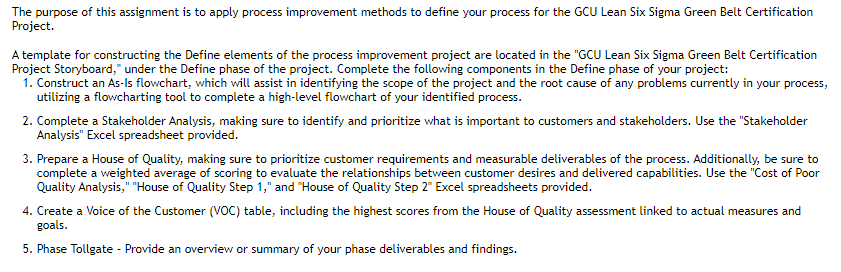

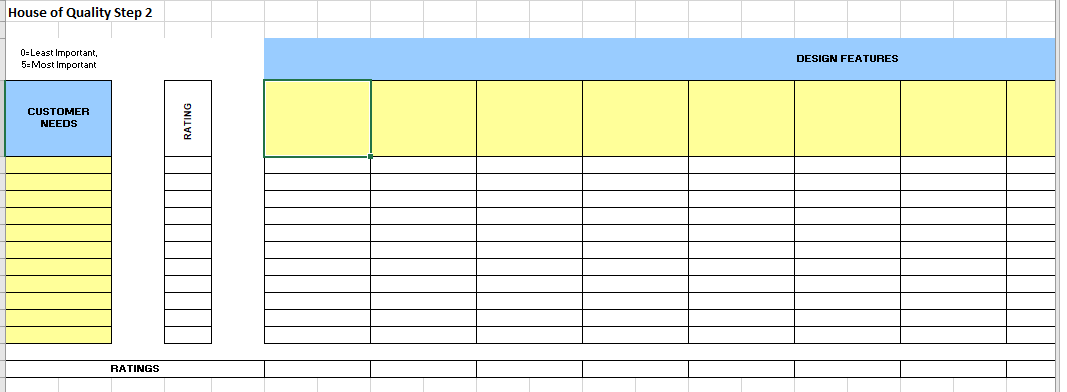

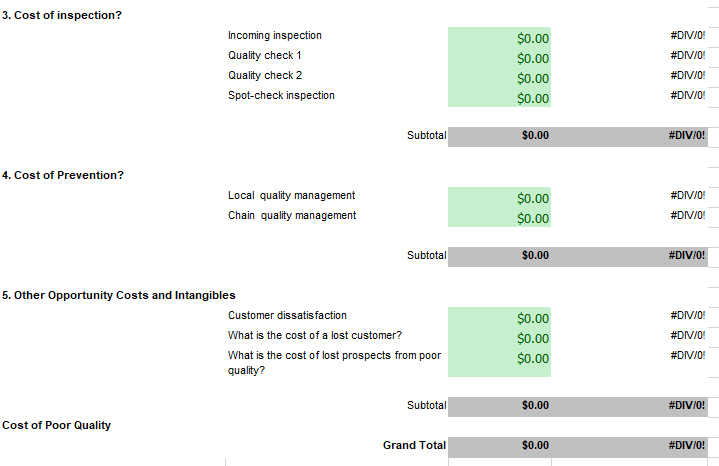

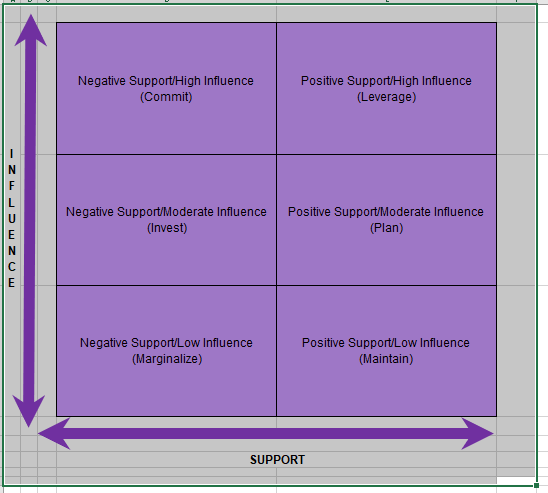

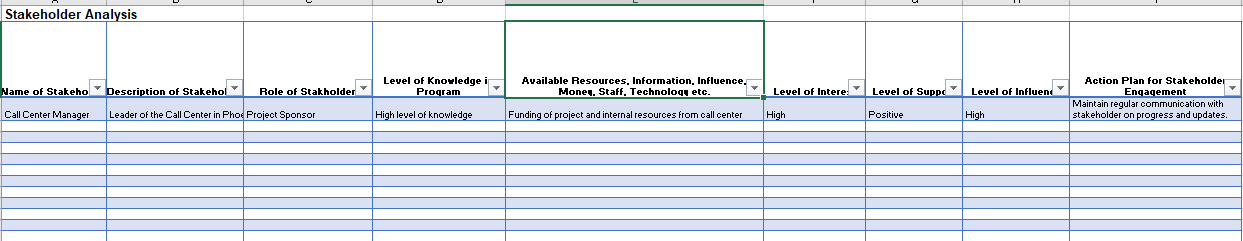

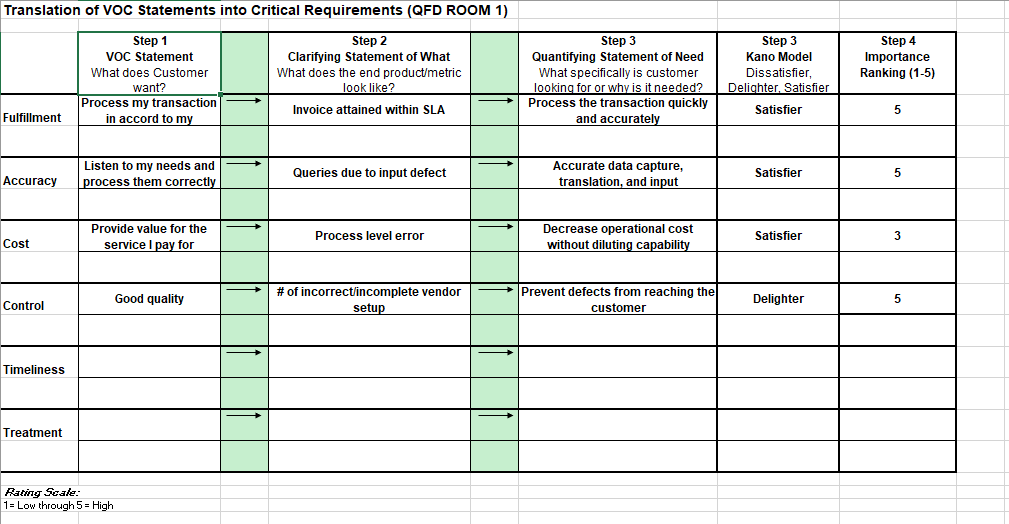

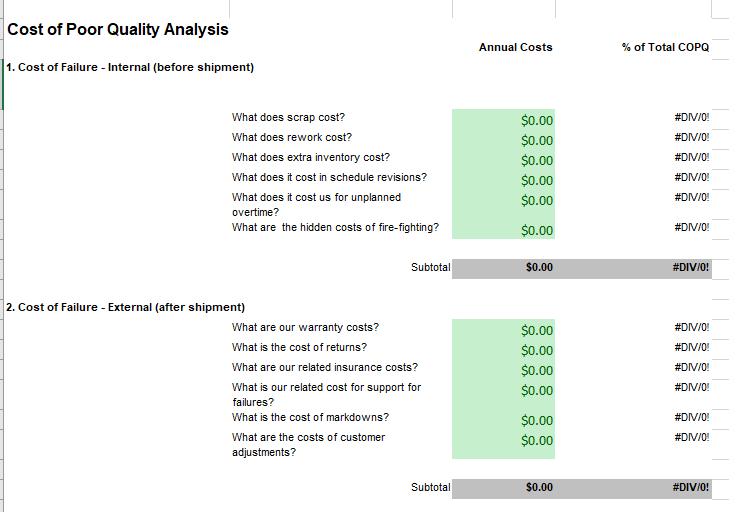

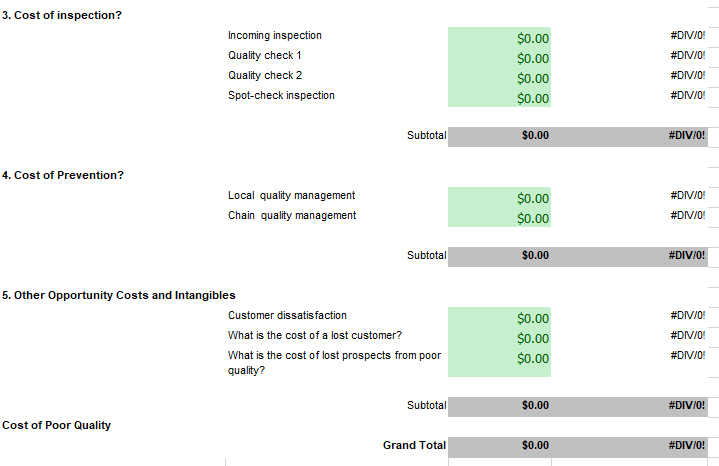

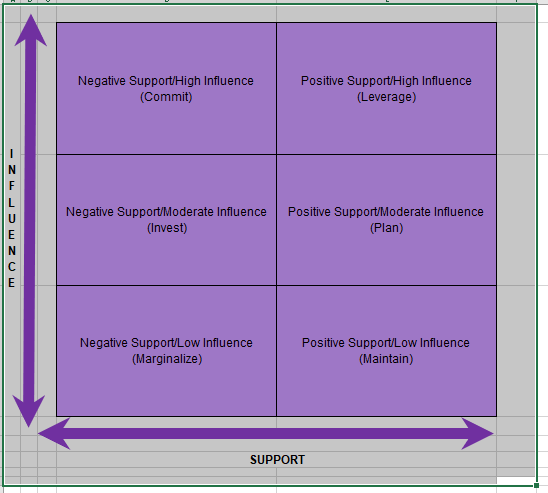

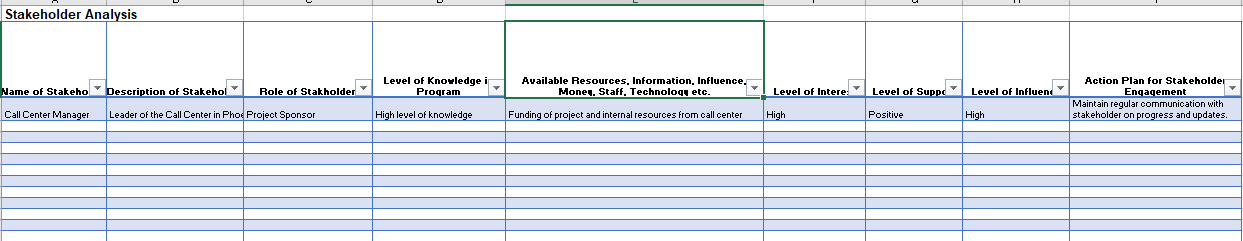

The purpose of this assignment is to apply process improvement methods to define your process for the GCU Lean Six Sigma Green Belt Certification Project. A template for constructing the Define elements of the process improvement project are located in the "GCU Lean Six Sigma Green Belt Certification Project Storyboard," under the Define phase of the project. Complete the following components in the Define phase of your project: 1. Construct an As-Is flowchart, which will assist in identifying the scope of the project and the root cause of any problems currently in your process, utilizing a flowcharting tool to complete a high-level flowchart of your identified process. 2. Complete a Stakeholder Analysis, making sure to identify and prioritize what is important to customers and stakeholders. Use the "Stakeholder Analysis" Excel spreadsheet provided. 3. Prepare a House of Quality, making sure to prioritize customer requirements and measurable deliverables of the process. Additionally, be sure to complete a weighted average of scoring to evaluate the relationships between customer desires and delivered capabilities. Use the "Cost of Poor Quality Analysis," "House of Quality Step 1," and "House of Quality Step 2* Excel spreadsheets provided. 4. Create a Voice of the Customer (VOC) table, including the highest scores from the House of Quality assessment linked to actual measures and goals. 5. Phase Tollgate - Provide an overview or summary of your phase deliverables and findings. Translation of VOC Statements into Critical Requirements (QFD ROOM 1) Step 1 VOC Statement What does Customer want? Process my transaction in accord to my Step 2 Clarifying Statement of What What does the end product/ metric look like? Step 3 Quantifying Statement of Need What specifically is customer looking for or why is it needed? Process the transaction quickly and accurately Step 3 Kano Model Dissatisfier, Delighter, Satisfier Satisfier Step 4 Importance Ranking (1-5) Invoice attained within SLA 5 Fulfillment Listen to my needs and process them correctly Queries due to input defect Accurate data capture, translation, and input Satisfier 5 Accuracy Provide value for the service I pay for Process level error Decrease operational cost without diluting capability Satisfier 3 Cost Good quality # of incorrect/incomplete vendor setup Control Prevent defects from reaching the customer Delighter 5 Timeliness Treatment Rating Scale: 1 = Low through 5 = High House of Quality Step 2 0-Least Important, 5-Most Important DESIGN FEATURES CUSTOMER NEEDS RATING RATINGS Cost of Poor Quality Analysis Annual Costs % of Total COPO 1. Cost of Failure - Internal (before shipment) #DIV/0! #DIV/0! What does scrap cost? What does rework cost? What does extra inventory cost? What does it cost in schedule revisions? What does it cost us for unplanned overtime? What are the hidden costs of fire-fighting? $0.00 $0.00 $0.00 $0.00 $0.00 #DIV/0! #DIV/0! #DIV/0! $0.00 #DIV/0! Subtotal $0.00 #DIV/0! #DIV/0! #DIV/0! #DIV/0! 2. Cost of Failure - External (after shipment) What are our warranty costs? What is the cost of returns? What are our related insurance costs? What is our related cost for support for failures? What is the cost of markdowns? What are the costs of customer adjustments? $0.00 $0.00 $0.00 $0.00 $0.00 $0.00 #DIV/0! #DIV/0! #DIV/0 Subtotal $0.00 #DIV/0! 3. Cost of inspection? #DIV/0! #DIV/0! Incoming inspection Quality check 1 Quality check 2 Spot-check inspection $0.00 $0.00 $0.00 $0.00 #DIV/0! #DIV/0! Subtotal $0.00 #DIV/0! 4. Cost of Prevention? #DIV/0! Local quality management Chain quality management $0.00 $0.00 #DIV/0! Subtotal $0.00 #DIV/0! #DIV/0! 5. Other Opportunity costs and Intangibles Customer dissatisfaction What is the cost of a lost customer? What is the cost of lost prospects from poor quality? $0.00 $0.00 $0.00 #DIV/0! #DIV/0! Subtotal $0.00 #DIV/0! Cost of Poor Quality Grand Total $0.00 #DIV/0! Negative Support/High Influence (Commit) Positive Support High Influence (Leverage) - Z w z Uw L U Negative Support/Moderate Influence (Invest) Positive Support/Moderate Influence (Plan) Negative Support/Low Influence (Marginalize) Positive Support Low Influence (Maintain) SUPPORT Stakeholder Analysis Level of knowledge i Program Name of Stakeho Description of Stakehol Role of Stakholder Available Resources, Information. Influence. Money. Staff, Technoloq, etc. Level of Intere: Level of Supp Level of Influen Action Plan for Stakeholder Engagement Maintain regular communication with stakeholder on progress and updates, Call Center Manager Leader of the Call Center in Phoe Project Sponsor High level of knowledge Funding of project and internal resources from call center High Positive High The purpose of this assignment is to apply process improvement methods to define your process for the GCU Lean Six Sigma Green Belt Certification Project. A template for constructing the Define elements of the process improvement project are located in the "GCU Lean Six Sigma Green Belt Certification Project Storyboard," under the Define phase of the project. Complete the following components in the Define phase of your project: 1. Construct an As-Is flowchart, which will assist in identifying the scope of the project and the root cause of any problems currently in your process, utilizing a flowcharting tool to complete a high-level flowchart of your identified process. 2. Complete a Stakeholder Analysis, making sure to identify and prioritize what is important to customers and stakeholders. Use the "Stakeholder Analysis" Excel spreadsheet provided. 3. Prepare a House of Quality, making sure to prioritize customer requirements and measurable deliverables of the process. Additionally, be sure to complete a weighted average of scoring to evaluate the relationships between customer desires and delivered capabilities. Use the "Cost of Poor Quality Analysis," "House of Quality Step 1," and "House of Quality Step 2* Excel spreadsheets provided. 4. Create a Voice of the Customer (VOC) table, including the highest scores from the House of Quality assessment linked to actual measures and goals. 5. Phase Tollgate - Provide an overview or summary of your phase deliverables and findings. Translation of VOC Statements into Critical Requirements (QFD ROOM 1) Step 1 VOC Statement What does Customer want? Process my transaction in accord to my Step 2 Clarifying Statement of What What does the end product/ metric look like? Step 3 Quantifying Statement of Need What specifically is customer looking for or why is it needed? Process the transaction quickly and accurately Step 3 Kano Model Dissatisfier, Delighter, Satisfier Satisfier Step 4 Importance Ranking (1-5) Invoice attained within SLA 5 Fulfillment Listen to my needs and process them correctly Queries due to input defect Accurate data capture, translation, and input Satisfier 5 Accuracy Provide value for the service I pay for Process level error Decrease operational cost without diluting capability Satisfier 3 Cost Good quality # of incorrect/incomplete vendor setup Control Prevent defects from reaching the customer Delighter 5 Timeliness Treatment Rating Scale: 1 = Low through 5 = High House of Quality Step 2 0-Least Important, 5-Most Important DESIGN FEATURES CUSTOMER NEEDS RATING RATINGS Cost of Poor Quality Analysis Annual Costs % of Total COPO 1. Cost of Failure - Internal (before shipment) #DIV/0! #DIV/0! What does scrap cost? What does rework cost? What does extra inventory cost? What does it cost in schedule revisions? What does it cost us for unplanned overtime? What are the hidden costs of fire-fighting? $0.00 $0.00 $0.00 $0.00 $0.00 #DIV/0! #DIV/0! #DIV/0! $0.00 #DIV/0! Subtotal $0.00 #DIV/0! #DIV/0! #DIV/0! #DIV/0! 2. Cost of Failure - External (after shipment) What are our warranty costs? What is the cost of returns? What are our related insurance costs? What is our related cost for support for failures? What is the cost of markdowns? What are the costs of customer adjustments? $0.00 $0.00 $0.00 $0.00 $0.00 $0.00 #DIV/0! #DIV/0! #DIV/0 Subtotal $0.00 #DIV/0! 3. Cost of inspection? #DIV/0! #DIV/0! Incoming inspection Quality check 1 Quality check 2 Spot-check inspection $0.00 $0.00 $0.00 $0.00 #DIV/0! #DIV/0! Subtotal $0.00 #DIV/0! 4. Cost of Prevention? #DIV/0! Local quality management Chain quality management $0.00 $0.00 #DIV/0! Subtotal $0.00 #DIV/0! #DIV/0! 5. Other Opportunity costs and Intangibles Customer dissatisfaction What is the cost of a lost customer? What is the cost of lost prospects from poor quality? $0.00 $0.00 $0.00 #DIV/0! #DIV/0! Subtotal $0.00 #DIV/0! Cost of Poor Quality Grand Total $0.00 #DIV/0! Negative Support/High Influence (Commit) Positive Support High Influence (Leverage) - Z w z Uw L U Negative Support/Moderate Influence (Invest) Positive Support/Moderate Influence (Plan) Negative Support/Low Influence (Marginalize) Positive Support Low Influence (Maintain) SUPPORT Stakeholder Analysis Level of knowledge i Program Name of Stakeho Description of Stakehol Role of Stakholder Available Resources, Information. Influence. Money. Staff, Technoloq, etc. Level of Intere: Level of Supp Level of Influen Action Plan for Stakeholder Engagement Maintain regular communication with stakeholder on progress and updates, Call Center Manager Leader of the Call Center in Phoe Project Sponsor High level of knowledge Funding of project and internal resources from call center High Positive High