Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Almond Perfection has been making products from almond nuts for over ten years. They make five products: almond oil (AO1), which is pure and

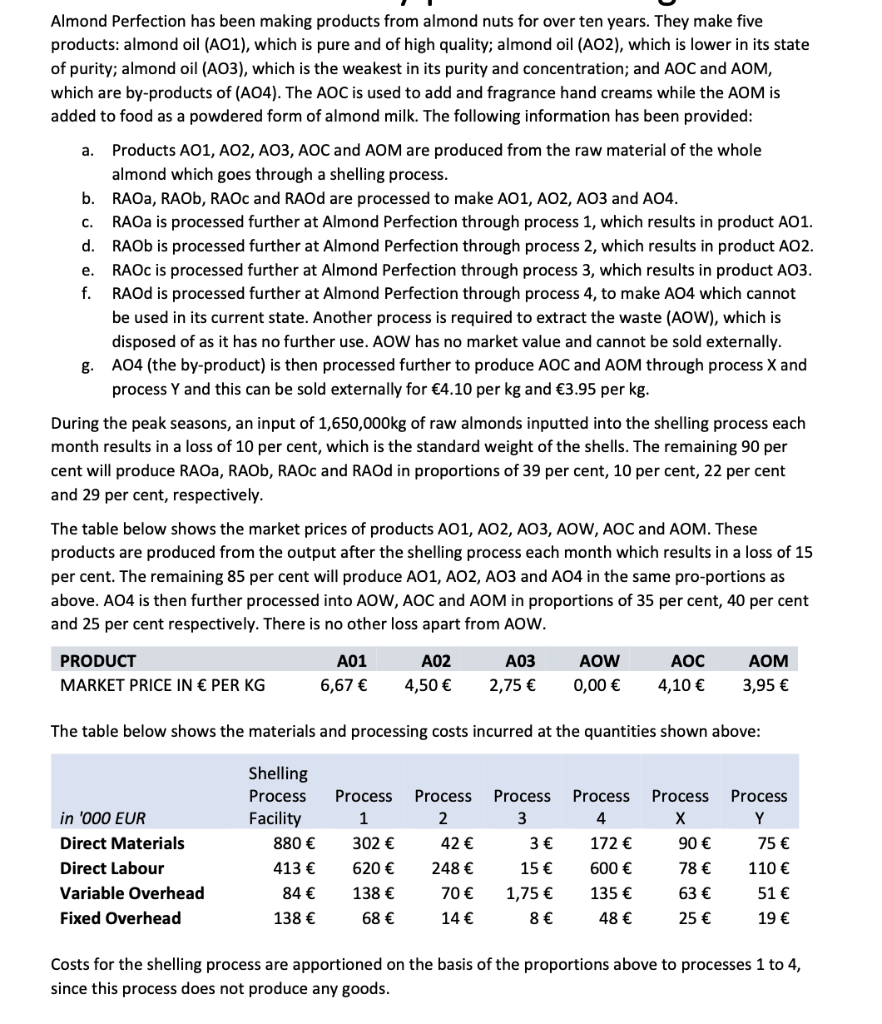

Almond Perfection has been making products from almond nuts for over ten years. They make five products: almond oil (AO1), which is pure and of high quality; almond oil (AO2), which is lower in its state of purity; almond oil (AO3), which is the weakest in its purity and concentration; and AOC and AOM, which are by-products of (AO4). The AOC is used to add and fragrance hand creams while the AOM is added to food as a powdered form of almond milk. The following information has been provided: Products AO1, AO2, AO3, AOC and AOM are produced from the raw material of the whole almond which goes through a shelling process. b. RAOa, RAOb, RAOC and RAOd are processed to make AO1, AO2, AO3 and AO4. C. e. RAOa is processed further at Almond Perfection through process 1, which results in product AO1. d. RAOb is processed further at Almond Perfection through process 2, which results in product AO2. RAOC is processed further at Almond Perfection through process 3, which results in product A03. f. RAOd is processed further at Almond Perfection through process 4, to make AO4 which cannot be used in its current state. Another process is required to extract the waste (AOW), which is disposed of as it has no further use. AOW has no market value and cannot be sold externally. AO4 (the by-product) is then processed further to produce AOC and AOM through process X and process Y and this can be sold externally for 4.10 per kg and 3.95 per kg. a. g. During the peak seasons, an input of 1,650,000kg of raw almonds inputted into the shelling process each month results in a loss of 10 per cent, which is the standard weight of the shells. The remaining 90 per cent will produce RAOa, RAOb, RAOC and RAOd in proportions of 39 per cent, 10 per cent, 22 per cent and 29 per cent, respectively. The table below shows the market prices of products AO1, AO2, AO3, AOW, AOC and AOM. These products are produced from the output after the shelling process each month which results in a loss of 15 per cent. The remaining 85 per cent will produce AO1, AO2, AO3 and AO4 in the same pro-portions as above. A04 is then further processed into AOW, AOC and AOM in proportions of 35 per cent, 40 per cent and 25 per cent respectively. There is no other loss apart from AOW. PRODUCT MARKET PRICE IN PER KG in '000 EUR Direct Materials Direct Labour Variable Overhead Fixed Overhead A01 6,67 880 413 84 138 A02 4,50 302 620 138 68 A03 2,75 The table below shows the materials and processing costs incurred at the quantities shown above: Shelling Process Facility Process Process Process 1 2 3 42 248 70 14 AOW 0,00 3 15 1,75 8 AOC 4,10 Process 4 172 600 135 48 AOM 3,95 Process X 90 78 63 25 Process Y 75 110 51 19 Costs for the shelling process are apportioned on the basis of the proportions above to processes 1 to 4, since this process does not produce any goods. 1. Calculate the input and output quantities for each stage of the manufacturing processes. Calculate the cost per unit of the finished almond products AO1, AO2, AO3, AOC and AOM. 3. Produce the T-accounts for all the processes. 4. Calculate which product would make a profit if they were to be sold at current market prices. Calculate the overall profit for Almond Perfection.

Step by Step Solution

★★★★★

3.47 Rating (147 Votes )

There are 3 Steps involved in it

Step: 1

1 Input and output quantities for each stage of the manufacturing processes Input Shelling process f...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started