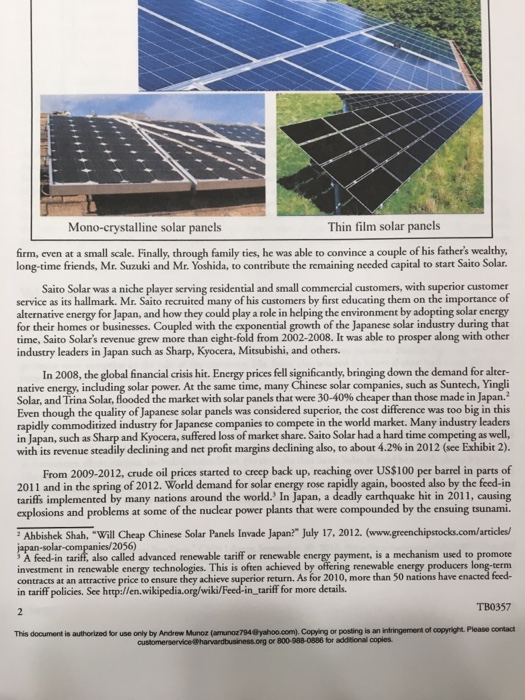

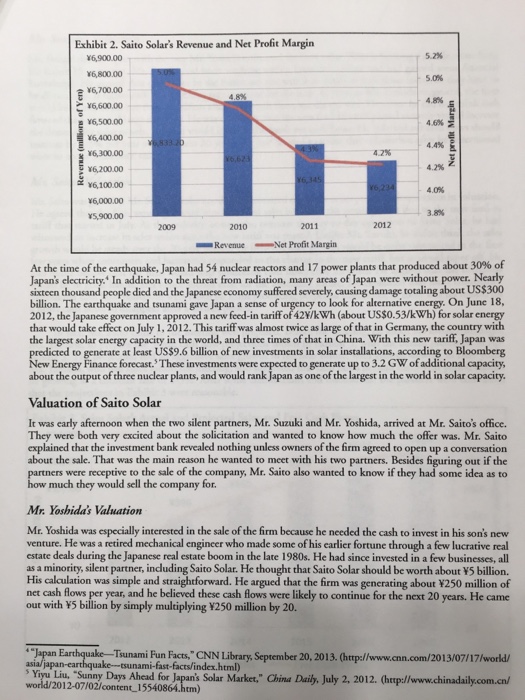

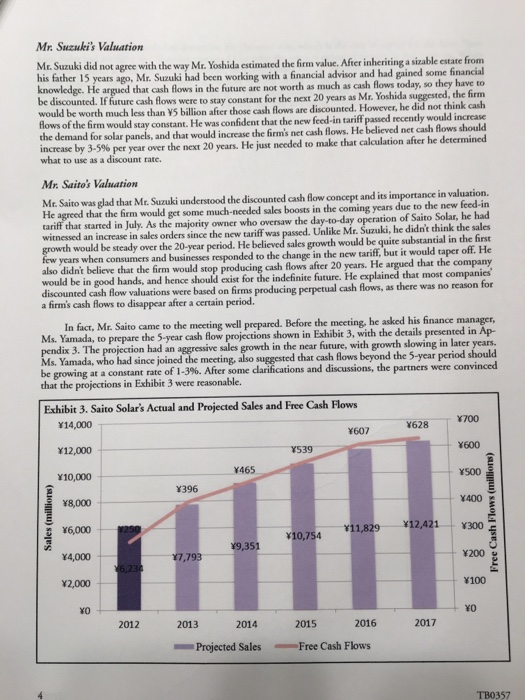

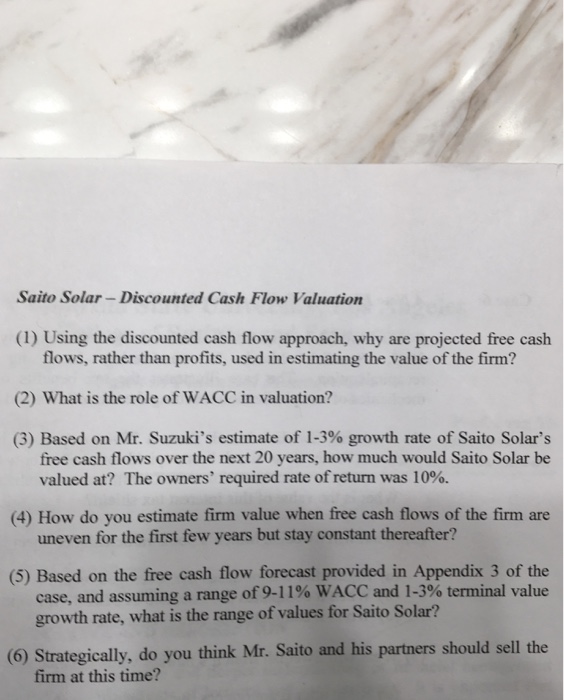

THUNDERBIRD TB0357 LENA BooTH FRANK TUzzOLINO SAITO SOLAR-DIScoUNTED CASH FLow VALUATION On a late November morning in 2012, a boutique investment bank in Japan approached Mr. Takuya Saito, founder and CEO of Saito Solar, about his interest in selling the firm. Even though selling the firm had crossed his mind occasionally in the past, Mt. Saito had never seriously thought about who would be a potential buyer and how much the firm could realistically be sold for. He was excited about the interest shown by the investment bank, yet skeptical about how large the offer might be, in light of the declining sales in recent years. Nevertheless, he invited his two silent partners, Mt. Kenta Suzuki and Mt. Shinji Yoshida, to gather in his office to discus this unsolicited proposal. Saito Solar and the Solar Energy Industry Saito Solar is a privately owned photovoltaic (PV) solar panel manufacturer founded by Mr. Takuya Saito in 2002 Mr. Saito worked as an clectrical engincer for Monsanto Electronic Materials Company (MEMC), a silicon-wafer company, right after finishing graduate school in the U.S. In 2000, after several years of dismal financial results MEMC was acquired by Texas Pacific Group, a private equity firm, for a symbolic dollar plus $150 million of credit lines. It was then that Mr. Saito decided to return to his homeland, Japan. Mr. Saito had always been intrigued by, and was a big believer in, alternative energy while he was in the U.S. He was particularly interested in solar energy and had spent many of his leisure ho electricity Multiple solar cells were then integrated into groups,all arranged on one plane, forming a solar panel. His research also showed that most of the solar panels in the world were made of either mono-crystalline or polycrystalline small fraction of the overall solar market. of solar energy production. He understood how solar cells, electrical devices that are used to generate from s photovoltaic effect, were connected electrically, usually in a series as a module. Mr. Saito believed Japanese residential and commercial properties would use a lot more solar energy if panels were durable and cost effective. After months of extensive industry research, he determined that solar Is made of polycrystalline silicon cells would have the most potential in Japan. Polycrystalline silicon costs ess to produce compared to mono-crystalline because in this process, raw silicon is melted and poured into a square mold, which is then cooled and cut into perfecly square wafers, resulting in less waste. While the efficiency level is slightly lower than mono-crystalline silicon, polycrystalline silicon-based solar panels are more cost effec- tive and would be very appealing in Japan, especially to residential customers. The thin-film solar panels, while cheap to manufacrure, are the least efficient in producing electricity. Thcy take up four times as much space as the mono-crystalline silicon-based panels to produce the same amount of electricity, making it very impractical for Japanese residential customers Mr. Saito spent the next few months soliciting capital to start his company. As a newcomer to the solar in dustry, he encountered many roadblocks, especially from banks and finance companies. Even though he had saved some moncy during the 20 years he worked at MEMC, it was not enough to start a solar panel manufacturing Machias Aarre Machlum, "Which Solar Panel Type is Best? Mono- vs. Polycrystalline vs. Thin Film," June 27, 2013. (http/lenergyinformative.org/best-solar-panel-monocrystalline-polycrystalline-thin-film/) Copyright 2013 Thunderbind School of Global Management. All rights reserved.This case uws prepared by Professers Lena Chwa Booth and Frank Tuzzolino for the purpose of classroom discussion only, and not to indicate either ofective or indffective