Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Read Case #2-3 found on page 42 of your text. Discuss in detail why it is important for an international company like Ford to

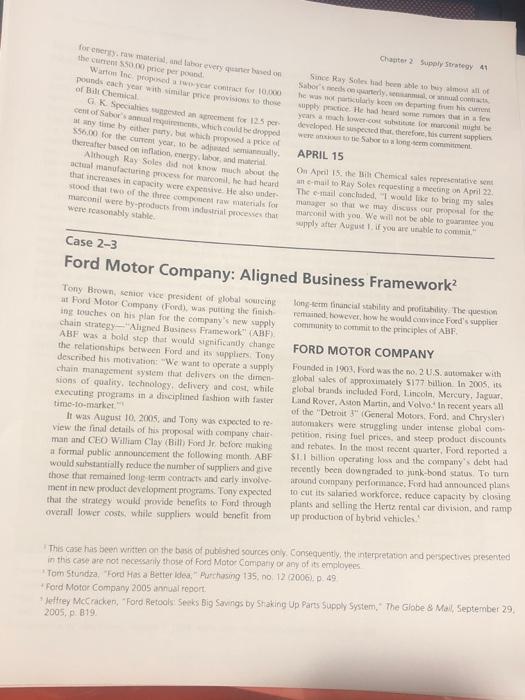

Read Case #2-3 found on page 42 of your text. Discuss in detail why it is important for an international company like Ford to implement an integrated supply chain. Consider the impact on the overall supply chain, international ramifications and the potential cost of failure in this endeavor. Post your response below using a minimum 300 words. Chapt e2 Supply Strategy 41 for energy, raw material, nd labor every quarter based on the cunent SsO 00 price per pound. Since Ray Soles had been able so biy almost all of Sabor's needs on uartery, enaanmual, or antual contacta he was o paticulay kee m depaning fnum his current supply prictice He had heard some nmos thut in a few years a mach lower-cost substinute for marcol mght be developed. He snpected that therefore, his current supplies were ansion to te Sabor t a long serm commitment Wartom Inc proposed a twoyear coract for 10000 pounds cach year with similar price provisions to those of Bilt Chemical G.K. Specialties uggeted an agreement for 125 per cent of Sabor's annal requiresens, which conld be dropped any time by eitber paty, bat which proposed a price of S56.00 for the current vear, to he adisted semianaally. thereafter based on inflation, energy, labor, and material Although Ray Soles did not know much about the actal manufacturine process for manconil, he had bcard that increases in capacity were expensive He also under- stood that two of the three componen raw materials for marconil were by-products from industrial processes that were reasonably stable. APRIL 15 On April 15, the Bih Chemical sales representative sent an e-mail to Ray Soles requesting a meeting on April 22. The e-mail conchaded, I woold like to bring my sales manager so that we may discuss our proposal for the marconil with you We will not be able to guarantee you supply after Auguit 1.f you are unable to commit." Case 2-3 Ford Motor Company: Aligned Business Framework? Tony Brown, senior vice president of global sourcing at Ford Motor Company (Ford), was putting the finish ing touches on his plan for the company's new sapply chain strategy"Aligned Business Framework" (ABF) ABF was a bold step that would significandy change the relationships between Ford and its soppliers. Tony described his motivation: "We want to operate a supply chain management system that delivers on the dimen- sions of quality, technology, delivery and cost, while executing programs in a disciplined fashion with faster time-to-marker." It was August 10, 2005, and Tony was expected to ne- view the final details of his proposal with company chair man and CEO William Clay (Bill) Ford Jr before making a formal public announcement the following month. ABF would substantially reduce the number of suppliers and give those that remained long lerm contracts and early involve ment in new product development programs. Tony expected that the strategy would provide benefits to Ford through overall lower costs, while suppliers would benefit from long-term tinuncial stability and profitability. The question remained, however, how he would ovince Ford's supplier community to commit to the principles of ABF. FORD MOTOR COMPANY Founded in 1903, Ford was the no. 2 U.S, automaker with global sales of approximately S177 billion In 2005, its global brands included Ford, Lincoln, Mercury, Jaguar. Land Rover, Aston Martin, and Volvo. In recent years all of the "Detroit 3" (General Motors. Ford. and Chrysler automakers were struggling under intense global com- petition, rising tuel prices, and steep product discounts and rebates. In the most recent quaiter, Ford reported a SL1 billion operating loss and the company's debt had recently been downgraded to junk-bond status. To turn around company performance, Ford had announced plans to cut its salaried workforce, reduce capacity by closing plants and selling the Hertz rental car division, and ramp up production of hybrid vehicles. This case has been written on the basis of published sources only. Consequenitly, the interpretation and perspectives presented in this case are not necessarily those of Ford Motor Compary or any of its employees Tom Stundza, "Ford Has a Better idea," Purchasing 135, no 12 (2006). p. 49 Ford Motor Company 2005 annual report Jeffrey McCracken, "Ford Retools Seeks Big Savings by Shaking Up Parts Supply System, The Globe & Mail, September 29,. 2005, p. B19. 42 Purchasing and Supply Management ALIGNED BUSINESS FRAMEWORK (ABF) The Ford global sopply chain included approsimanely 2500 prodoction and 9000 nongroduction suppliers, with operations in more than 60 countries, suoponing 107 Ford manufacturing sites. Total porchanes in 2005 were more than $90 billioe for roughly 25o production commodi ties (eg. seats, heating and cooling systems, addvanced electronies and steering systems) and S00 nonproduc- tion commodities ieg. health care, software, logistics and marketing and advertising services). The more than 130.000 active production parns accounted for approxi mutely S70 billion of total annoal purchases Historically Ford leaned heavily on soppliers for annual across-the-board price reductiens that averaged approximately 3 percent, although requests for more substantial reductions were commonplace. This environ- ment had created contemptuous relationships between Ford and its suppliers, which were reinforced through annual performmance evaluations and bonuses for buyers based on achieving year-over-year price reduction ob- jectives. The foundation of the new ABF strategy was a cultural shift from confrontational to collaborative upplier elationihips Tony commened an his e ment of Fond's curtent upply chain strategy "We have *problem wite the bosines model in this indistry. It is net working effectively for our soppliers I is not wock- ing elfectively for us. When my day i dominated by TAses related to financally distressed sappliers. com modity price shocks, quality problemis and conts sun, A's clear so me that there init be a better approsch. ABF sargeted companywide cost reductions of 10 percent of Ford's annual spend of production parts by 2010-57 hillion per year-by adopting what Tony considered best practices approach lo supply chain munagement and supplier partnerships "t's an envi- roment hetween Ferd and a select family of suppliers where innovative ideas can emerge, and then be incu- bated, evaluated and incorpocated into our products Under the new system, preferred suppliers would be matched with Ford purchasing and engineering manag- ers to work on projects to achieve quality, cost, and de livery goals. The 20 key elements of the ABF that Tony planned to propose are provided in Exhibit 1, which Brown described as "a kinder, gentler era of coopera- tion from global suppliers that can be implemented be- yond North America EXHIBIT 1 Key Elements of ABF Ford Commitments Bilateral Commitments Supplier Commitments Achieve best-in-class quality Data transparency Agree on detailed cost models Focus on total costs, included elimination of emphasis on bins Competitive cost at Job no. 1, with less emphasis on year- over-year price reductions Share current financial data to demonstrate health Backstop other commodity suppliers Marage and assure proper working conditions in their facilities and in the facilities of sub-tiers Sourcing of minority- and women-owned suppliers Use mutually agreeable multi- party agreement in directed tier 2 sourcing scenarios Technological innovations will be provided to Ford - Up-front reimbursement of supplier engineering, design and testing Long-term sourcing Improved comimonaity and reuse Improved product, cycle plan, and forecast volume stability Sharing of forecast volumes and . Open collaboration on global product plans (beyond 3 years) More disciplined program ex- ecution through Ford Global Product Development system manufacturing, engineering footprint Ongoing senior leadership communication Data exchange remains confidential www.ford.com/aboutfordmicrosites/sustainability-report-2006-07 "Stundra, "Ford Has a Better idea, p 49 Ibid. id. * Presentation by Tony Brown, October 7, 2005, www.oesa orgiemspagesigetAtch php?id=180 Chapter 2 Supply Strategy 43 Tony was proposing thut in the finst phise of the ARF iniplememation, his supply organization would focs on 20 high-impac commodity groups, vach an seats, tines and bumpers where the automaker spent approsimatety 535 billon per yen with 200 suppliers The plan was reduce the munher of suppliers for these cmmodities to 100 by the 2009 model year In the long tem. Tony's ohjective was to drink the production supply hane from 2.500 o 1000 from greter callaborution, udy supplier nvolvemem in new producr development, and pplier inovation How WIild the adseciuned costa and benefits be easued and shared among Ford and ts uppliens Font had u decades-long teadition of contrommational relationships with its supplier community, A rocent wir- vey of North American utomotie tier 1 suppliers tanked Font secondto last with a score of 157 verss tiranked Toyota at 415 and Honda a 175 (cale 500 =very good, 0very poor." Tuming around relutionships with aap- pliers could uke yeurs. Civen the difficult times in the industry and at Ford. Tony knew that Bill Ford would have questions about supplier skepticism reganding the company's metivations behind ABF and how quckly the plun would start to show results Tony Brown believed that it was neceisary to make major changes to Ford's supply chain if the company was going to survive Av he got ready for his meeting with Mr. Ford, Tony pondered how he should proceed with implementatisn, and specifically how suppliers could be convinced to biy into the principles of ABF. Tony com mented on the chullenges that ABF presented:This is no business as usual We're not only asking sur suppliers to iep up. We're aso asking ourselves to step up. FINALIZING THE PLAN Tony recognized that there would be a great many ques tions from other Ford executives, members of his par- chasing organization and suppliers regarding bow ABF would be implemented There were obviously going to be winners and losers from the esisting Ford supplier com munity under ABF and many of Ford's existing suppliers would have to be told that they would not be participating in future prograns The prefemed suppliers would have many questions regarding how their relationships would function with Ford in the future. For example. it was ex- pected that suppliers would benefit from hugher capacity utilization as a resalt of the inereased production vol umes. Furthermore, adkditional benefits were anticipated Read Case #2-3 found on page 42 of your text. Discuss in detail why it is important for an international company like Ford to implement an integrated supply chain. Consider the impact on the overall supply chain, international ramifications and the potential cost of failure in this endeavor. Post your response below using a minimum 300 words. Chapt e2 Supply Strategy 41 for energy, raw material, nd labor every quarter based on the cunent SsO 00 price per pound. Since Ray Soles had been able so biy almost all of Sabor's needs on uartery, enaanmual, or antual contacta he was o paticulay kee m depaning fnum his current supply prictice He had heard some nmos thut in a few years a mach lower-cost substinute for marcol mght be developed. He snpected that therefore, his current supplies were ansion to te Sabor t a long serm commitment Wartom Inc proposed a twoyear coract for 10000 pounds cach year with similar price provisions to those of Bilt Chemical G.K. Specialties uggeted an agreement for 125 per cent of Sabor's annal requiresens, which conld be dropped any time by eitber paty, bat which proposed a price of S56.00 for the current vear, to he adisted semianaally. thereafter based on inflation, energy, labor, and material Although Ray Soles did not know much about the actal manufacturine process for manconil, he had bcard that increases in capacity were expensive He also under- stood that two of the three componen raw materials for marconil were by-products from industrial processes that were reasonably stable. APRIL 15 On April 15, the Bih Chemical sales representative sent an e-mail to Ray Soles requesting a meeting on April 22. The e-mail conchaded, I woold like to bring my sales manager so that we may discuss our proposal for the marconil with you We will not be able to guarantee you supply after Auguit 1.f you are unable to commit." Case 2-3 Ford Motor Company: Aligned Business Framework? Tony Brown, senior vice president of global sourcing at Ford Motor Company (Ford), was putting the finish ing touches on his plan for the company's new sapply chain strategy"Aligned Business Framework" (ABF) ABF was a bold step that would significandy change the relationships between Ford and its soppliers. Tony described his motivation: "We want to operate a supply chain management system that delivers on the dimen- sions of quality, technology, delivery and cost, while executing programs in a disciplined fashion with faster time-to-marker." It was August 10, 2005, and Tony was expected to ne- view the final details of his proposal with company chair man and CEO William Clay (Bill) Ford Jr before making a formal public announcement the following month. ABF would substantially reduce the number of suppliers and give those that remained long lerm contracts and early involve ment in new product development programs. Tony expected that the strategy would provide benefits to Ford through overall lower costs, while suppliers would benefit from long-term tinuncial stability and profitability. The question remained, however, how he would ovince Ford's supplier community to commit to the principles of ABF. FORD MOTOR COMPANY Founded in 1903, Ford was the no. 2 U.S, automaker with global sales of approximately S177 billion In 2005, its global brands included Ford, Lincoln, Mercury, Jaguar. Land Rover, Aston Martin, and Volvo. In recent years all of the "Detroit 3" (General Motors. Ford. and Chrysler automakers were struggling under intense global com- petition, rising tuel prices, and steep product discounts and rebates. In the most recent quaiter, Ford reported a SL1 billion operating loss and the company's debt had recently been downgraded to junk-bond status. To turn around company performance, Ford had announced plans to cut its salaried workforce, reduce capacity by closing plants and selling the Hertz rental car division, and ramp up production of hybrid vehicles. This case has been written on the basis of published sources only. Consequenitly, the interpretation and perspectives presented in this case are not necessarily those of Ford Motor Compary or any of its employees Tom Stundza, "Ford Has a Better idea," Purchasing 135, no 12 (2006). p. 49 Ford Motor Company 2005 annual report Jeffrey McCracken, "Ford Retools Seeks Big Savings by Shaking Up Parts Supply System, The Globe & Mail, September 29,. 2005, p. B19. 42 Purchasing and Supply Management ALIGNED BUSINESS FRAMEWORK (ABF) The Ford global sopply chain included approsimanely 2500 prodoction and 9000 nongroduction suppliers, with operations in more than 60 countries, suoponing 107 Ford manufacturing sites. Total porchanes in 2005 were more than $90 billioe for roughly 25o production commodi ties (eg. seats, heating and cooling systems, addvanced electronies and steering systems) and S00 nonproduc- tion commodities ieg. health care, software, logistics and marketing and advertising services). The more than 130.000 active production parns accounted for approxi mutely S70 billion of total annoal purchases Historically Ford leaned heavily on soppliers for annual across-the-board price reductiens that averaged approximately 3 percent, although requests for more substantial reductions were commonplace. This environ- ment had created contemptuous relationships between Ford and its suppliers, which were reinforced through annual performmance evaluations and bonuses for buyers based on achieving year-over-year price reduction ob- jectives. The foundation of the new ABF strategy was a cultural shift from confrontational to collaborative upplier elationihips Tony commened an his e ment of Fond's curtent upply chain strategy "We have *problem wite the bosines model in this indistry. It is net working effectively for our soppliers I is not wock- ing elfectively for us. When my day i dominated by TAses related to financally distressed sappliers. com modity price shocks, quality problemis and conts sun, A's clear so me that there init be a better approsch. ABF sargeted companywide cost reductions of 10 percent of Ford's annual spend of production parts by 2010-57 hillion per year-by adopting what Tony considered best practices approach lo supply chain munagement and supplier partnerships "t's an envi- roment hetween Ferd and a select family of suppliers where innovative ideas can emerge, and then be incu- bated, evaluated and incorpocated into our products Under the new system, preferred suppliers would be matched with Ford purchasing and engineering manag- ers to work on projects to achieve quality, cost, and de livery goals. The 20 key elements of the ABF that Tony planned to propose are provided in Exhibit 1, which Brown described as "a kinder, gentler era of coopera- tion from global suppliers that can be implemented be- yond North America EXHIBIT 1 Key Elements of ABF Ford Commitments Bilateral Commitments Supplier Commitments Achieve best-in-class quality Data transparency Agree on detailed cost models Focus on total costs, included elimination of emphasis on bins Competitive cost at Job no. 1, with less emphasis on year- over-year price reductions Share current financial data to demonstrate health Backstop other commodity suppliers Marage and assure proper working conditions in their facilities and in the facilities of sub-tiers Sourcing of minority- and women-owned suppliers Use mutually agreeable multi- party agreement in directed tier 2 sourcing scenarios Technological innovations will be provided to Ford - Up-front reimbursement of supplier engineering, design and testing Long-term sourcing Improved comimonaity and reuse Improved product, cycle plan, and forecast volume stability Sharing of forecast volumes and . Open collaboration on global product plans (beyond 3 years) More disciplined program ex- ecution through Ford Global Product Development system manufacturing, engineering footprint Ongoing senior leadership communication Data exchange remains confidential www.ford.com/aboutfordmicrosites/sustainability-report-2006-07 "Stundra, "Ford Has a Better idea, p 49 Ibid. id. * Presentation by Tony Brown, October 7, 2005, www.oesa orgiemspagesigetAtch php?id=180 Chapter 2 Supply Strategy 43 Tony was proposing thut in the finst phise of the ARF iniplememation, his supply organization would focs on 20 high-impac commodity groups, vach an seats, tines and bumpers where the automaker spent approsimatety 535 billon per yen with 200 suppliers The plan was reduce the munher of suppliers for these cmmodities to 100 by the 2009 model year In the long tem. Tony's ohjective was to drink the production supply hane from 2.500 o 1000 from greter callaborution, udy supplier nvolvemem in new producr development, and pplier inovation How WIild the adseciuned costa and benefits be easued and shared among Ford and ts uppliens Font had u decades-long teadition of contrommational relationships with its supplier community, A rocent wir- vey of North American utomotie tier 1 suppliers tanked Font secondto last with a score of 157 verss tiranked Toyota at 415 and Honda a 175 (cale 500 =very good, 0very poor." Tuming around relutionships with aap- pliers could uke yeurs. Civen the difficult times in the industry and at Ford. Tony knew that Bill Ford would have questions about supplier skepticism reganding the company's metivations behind ABF and how quckly the plun would start to show results Tony Brown believed that it was neceisary to make major changes to Ford's supply chain if the company was going to survive Av he got ready for his meeting with Mr. Ford, Tony pondered how he should proceed with implementatisn, and specifically how suppliers could be convinced to biy into the principles of ABF. Tony com mented on the chullenges that ABF presented:This is no business as usual We're not only asking sur suppliers to iep up. We're aso asking ourselves to step up. FINALIZING THE PLAN Tony recognized that there would be a great many ques tions from other Ford executives, members of his par- chasing organization and suppliers regarding bow ABF would be implemented There were obviously going to be winners and losers from the esisting Ford supplier com munity under ABF and many of Ford's existing suppliers would have to be told that they would not be participating in future prograns The prefemed suppliers would have many questions regarding how their relationships would function with Ford in the future. For example. it was ex- pected that suppliers would benefit from hugher capacity utilization as a resalt of the inereased production vol umes. Furthermore, adkditional benefits were anticipated Read Case #2-3 found on page 42 of your text. Discuss in detail why it is important for an international company like Ford to implement an integrated supply chain. Consider the impact on the overall supply chain, international ramifications and the potential cost of failure in this endeavor. Post your response below using a minimum 300 words. Chapt e2 Supply Strategy 41 for energy, raw material, nd labor every quarter based on the cunent SsO 00 price per pound. Since Ray Soles had been able so biy almost all of Sabor's needs on uartery, enaanmual, or antual contacta he was o paticulay kee m depaning fnum his current supply prictice He had heard some nmos thut in a few years a mach lower-cost substinute for marcol mght be developed. He snpected that therefore, his current supplies were ansion to te Sabor t a long serm commitment Wartom Inc proposed a twoyear coract for 10000 pounds cach year with similar price provisions to those of Bilt Chemical G.K. Specialties uggeted an agreement for 125 per cent of Sabor's annal requiresens, which conld be dropped any time by eitber paty, bat which proposed a price of S56.00 for the current vear, to he adisted semianaally. thereafter based on inflation, energy, labor, and material Although Ray Soles did not know much about the actal manufacturine process for manconil, he had bcard that increases in capacity were expensive He also under- stood that two of the three componen raw materials for marconil were by-products from industrial processes that were reasonably stable. APRIL 15 On April 15, the Bih Chemical sales representative sent an e-mail to Ray Soles requesting a meeting on April 22. The e-mail conchaded, I woold like to bring my sales manager so that we may discuss our proposal for the marconil with you We will not be able to guarantee you supply after Auguit 1.f you are unable to commit." Case 2-3 Ford Motor Company: Aligned Business Framework? Tony Brown, senior vice president of global sourcing at Ford Motor Company (Ford), was putting the finish ing touches on his plan for the company's new sapply chain strategy"Aligned Business Framework" (ABF) ABF was a bold step that would significandy change the relationships between Ford and its soppliers. Tony described his motivation: "We want to operate a supply chain management system that delivers on the dimen- sions of quality, technology, delivery and cost, while executing programs in a disciplined fashion with faster time-to-marker." It was August 10, 2005, and Tony was expected to ne- view the final details of his proposal with company chair man and CEO William Clay (Bill) Ford Jr before making a formal public announcement the following month. ABF would substantially reduce the number of suppliers and give those that remained long lerm contracts and early involve ment in new product development programs. Tony expected that the strategy would provide benefits to Ford through overall lower costs, while suppliers would benefit from long-term tinuncial stability and profitability. The question remained, however, how he would ovince Ford's supplier community to commit to the principles of ABF. FORD MOTOR COMPANY Founded in 1903, Ford was the no. 2 U.S, automaker with global sales of approximately S177 billion In 2005, its global brands included Ford, Lincoln, Mercury, Jaguar. Land Rover, Aston Martin, and Volvo. In recent years all of the "Detroit 3" (General Motors. Ford. and Chrysler automakers were struggling under intense global com- petition, rising tuel prices, and steep product discounts and rebates. In the most recent quaiter, Ford reported a SL1 billion operating loss and the company's debt had recently been downgraded to junk-bond status. To turn around company performance, Ford had announced plans to cut its salaried workforce, reduce capacity by closing plants and selling the Hertz rental car division, and ramp up production of hybrid vehicles. This case has been written on the basis of published sources only. Consequenitly, the interpretation and perspectives presented in this case are not necessarily those of Ford Motor Compary or any of its employees Tom Stundza, "Ford Has a Better idea," Purchasing 135, no 12 (2006). p. 49 Ford Motor Company 2005 annual report Jeffrey McCracken, "Ford Retools Seeks Big Savings by Shaking Up Parts Supply System, The Globe & Mail, September 29,. 2005, p. B19. 42 Purchasing and Supply Management ALIGNED BUSINESS FRAMEWORK (ABF) The Ford global sopply chain included approsimanely 2500 prodoction and 9000 nongroduction suppliers, with operations in more than 60 countries, suoponing 107 Ford manufacturing sites. Total porchanes in 2005 were more than $90 billioe for roughly 25o production commodi ties (eg. seats, heating and cooling systems, addvanced electronies and steering systems) and S00 nonproduc- tion commodities ieg. health care, software, logistics and marketing and advertising services). The more than 130.000 active production parns accounted for approxi mutely S70 billion of total annoal purchases Historically Ford leaned heavily on soppliers for annual across-the-board price reductiens that averaged approximately 3 percent, although requests for more substantial reductions were commonplace. This environ- ment had created contemptuous relationships between Ford and its suppliers, which were reinforced through annual performmance evaluations and bonuses for buyers based on achieving year-over-year price reduction ob- jectives. The foundation of the new ABF strategy was a cultural shift from confrontational to collaborative upplier elationihips Tony commened an his e ment of Fond's curtent upply chain strategy "We have *problem wite the bosines model in this indistry. It is net working effectively for our soppliers I is not wock- ing elfectively for us. When my day i dominated by TAses related to financally distressed sappliers. com modity price shocks, quality problemis and conts sun, A's clear so me that there init be a better approsch. ABF sargeted companywide cost reductions of 10 percent of Ford's annual spend of production parts by 2010-57 hillion per year-by adopting what Tony considered best practices approach lo supply chain munagement and supplier partnerships "t's an envi- roment hetween Ferd and a select family of suppliers where innovative ideas can emerge, and then be incu- bated, evaluated and incorpocated into our products Under the new system, preferred suppliers would be matched with Ford purchasing and engineering manag- ers to work on projects to achieve quality, cost, and de livery goals. The 20 key elements of the ABF that Tony planned to propose are provided in Exhibit 1, which Brown described as "a kinder, gentler era of coopera- tion from global suppliers that can be implemented be- yond North America EXHIBIT 1 Key Elements of ABF Ford Commitments Bilateral Commitments Supplier Commitments Achieve best-in-class quality Data transparency Agree on detailed cost models Focus on total costs, included elimination of emphasis on bins Competitive cost at Job no. 1, with less emphasis on year- over-year price reductions Share current financial data to demonstrate health Backstop other commodity suppliers Marage and assure proper working conditions in their facilities and in the facilities of sub-tiers Sourcing of minority- and women-owned suppliers Use mutually agreeable multi- party agreement in directed tier 2 sourcing scenarios Technological innovations will be provided to Ford - Up-front reimbursement of supplier engineering, design and testing Long-term sourcing Improved comimonaity and reuse Improved product, cycle plan, and forecast volume stability Sharing of forecast volumes and . Open collaboration on global product plans (beyond 3 years) More disciplined program ex- ecution through Ford Global Product Development system manufacturing, engineering footprint Ongoing senior leadership communication Data exchange remains confidential www.ford.com/aboutfordmicrosites/sustainability-report-2006-07 "Stundra, "Ford Has a Better idea, p 49 Ibid. id. * Presentation by Tony Brown, October 7, 2005, www.oesa orgiemspagesigetAtch php?id=180 Chapter 2 Supply Strategy 43 Tony was proposing thut in the finst phise of the ARF iniplememation, his supply organization would focs on 20 high-impac commodity groups, vach an seats, tines and bumpers where the automaker spent approsimatety 535 billon per yen with 200 suppliers The plan was reduce the munher of suppliers for these cmmodities to 100 by the 2009 model year In the long tem. Tony's ohjective was to drink the production supply hane from 2.500 o 1000 from greter callaborution, udy supplier nvolvemem in new producr development, and pplier inovation How WIild the adseciuned costa and benefits be easued and shared among Ford and ts uppliens Font had u decades-long teadition of contrommational relationships with its supplier community, A rocent wir- vey of North American utomotie tier 1 suppliers tanked Font secondto last with a score of 157 verss tiranked Toyota at 415 and Honda a 175 (cale 500 =very good, 0very poor." Tuming around relutionships with aap- pliers could uke yeurs. Civen the difficult times in the industry and at Ford. Tony knew that Bill Ford would have questions about supplier skepticism reganding the company's metivations behind ABF and how quckly the plun would start to show results Tony Brown believed that it was neceisary to make major changes to Ford's supply chain if the company was going to survive Av he got ready for his meeting with Mr. Ford, Tony pondered how he should proceed with implementatisn, and specifically how suppliers could be convinced to biy into the principles of ABF. Tony com mented on the chullenges that ABF presented:This is no business as usual We're not only asking sur suppliers to iep up. We're aso asking ourselves to step up. FINALIZING THE PLAN Tony recognized that there would be a great many ques tions from other Ford executives, members of his par- chasing organization and suppliers regarding bow ABF would be implemented There were obviously going to be winners and losers from the esisting Ford supplier com munity under ABF and many of Ford's existing suppliers would have to be told that they would not be participating in future prograns The prefemed suppliers would have many questions regarding how their relationships would function with Ford in the future. For example. it was ex- pected that suppliers would benefit from hugher capacity utilization as a resalt of the inereased production vol umes. Furthermore, adkditional benefits were anticipated Read Case #2-3 found on page 42 of your text. Discuss in detail why it is important for an international company like Ford to implement an integrated supply chain. Consider the impact on the overall supply chain, international ramifications and the potential cost of failure in this endeavor. Post your response below using a minimum 300 words. Chapt e2 Supply Strategy 41 for energy, raw material, nd labor every quarter based on the cunent SsO 00 price per pound. Since Ray Soles had been able so biy almost all of Sabor's needs on uartery, enaanmual, or antual contacta he was o paticulay kee m depaning fnum his current supply prictice He had heard some nmos thut in a few years a mach lower-cost substinute for marcol mght be developed. He snpected that therefore, his current supplies were ansion to te Sabor t a long serm commitment Wartom Inc proposed a twoyear coract for 10000 pounds cach year with similar price provisions to those of Bilt Chemical G.K. Specialties uggeted an agreement for 125 per cent of Sabor's annal requiresens, which conld be dropped any time by eitber paty, bat which proposed a price of S56.00 for the current vear, to he adisted semianaally. thereafter based on inflation, energy, labor, and material Although Ray Soles did not know much about the actal manufacturine process for manconil, he had bcard that increases in capacity were expensive He also under- stood that two of the three componen raw materials for marconil were by-products from industrial processes that were reasonably stable. APRIL 15 On April 15, the Bih Chemical sales representative sent an e-mail to Ray Soles requesting a meeting on April 22. The e-mail conchaded, I woold like to bring my sales manager so that we may discuss our proposal for the marconil with you We will not be able to guarantee you supply after Auguit 1.f you are unable to commit." Case 2-3 Ford Motor Company: Aligned Business Framework? Tony Brown, senior vice president of global sourcing at Ford Motor Company (Ford), was putting the finish ing touches on his plan for the company's new sapply chain strategy"Aligned Business Framework" (ABF) ABF was a bold step that would significandy change the relationships between Ford and its soppliers. Tony described his motivation: "We want to operate a supply chain management system that delivers on the dimen- sions of quality, technology, delivery and cost, while executing programs in a disciplined fashion with faster time-to-marker." It was August 10, 2005, and Tony was expected to ne- view the final details of his proposal with company chair man and CEO William Clay (Bill) Ford Jr before making a formal public announcement the following month. ABF would substantially reduce the number of suppliers and give those that remained long lerm contracts and early involve ment in new product development programs. Tony expected that the strategy would provide benefits to Ford through overall lower costs, while suppliers would benefit from long-term tinuncial stability and profitability. The question remained, however, how he would ovince Ford's supplier community to commit to the principles of ABF. FORD MOTOR COMPANY Founded in 1903, Ford was the no. 2 U.S, automaker with global sales of approximately S177 billion In 2005, its global brands included Ford, Lincoln, Mercury, Jaguar. Land Rover, Aston Martin, and Volvo. In recent years all of the "Detroit 3" (General Motors. Ford. and Chrysler automakers were struggling under intense global com- petition, rising tuel prices, and steep product discounts and rebates. In the most recent quaiter, Ford reported a SL1 billion operating loss and the company's debt had recently been downgraded to junk-bond status. To turn around company performance, Ford had announced plans to cut its salaried workforce, reduce capacity by closing plants and selling the Hertz rental car division, and ramp up production of hybrid vehicles. This case has been written on the basis of published sources only. Consequenitly, the interpretation and perspectives presented in this case are not necessarily those of Ford Motor Compary or any of its employees Tom Stundza, "Ford Has a Better idea," Purchasing 135, no 12 (2006). p. 49 Ford Motor Company 2005 annual report Jeffrey McCracken, "Ford Retools Seeks Big Savings by Shaking Up Parts Supply System, The Globe & Mail, September 29,. 2005, p. B19. 42 Purchasing and Supply Management ALIGNED BUSINESS FRAMEWORK (ABF) The Ford global sopply chain included approsimanely 2500 prodoction and 9000 nongroduction suppliers, with operations in more than 60 countries, suoponing 107 Ford manufacturing sites. Total porchanes in 2005 were more than $90 billioe for roughly 25o production commodi ties (eg. seats, heating and cooling systems, addvanced electronies and steering systems) and S00 nonproduc- tion commodities ieg. health care, software, logistics and marketing and advertising services). The more than 130.000 active production parns accounted for approxi mutely S70 billion of total annoal purchases Historically Ford leaned heavily on soppliers for annual across-the-board price reductiens that averaged approximately 3 percent, although requests for more substantial reductions were commonplace. This environ- ment had created contemptuous relationships between Ford and its suppliers, which were reinforced through annual performmance evaluations and bonuses for buyers based on achieving year-over-year price reduction ob- jectives. The foundation of the new ABF strategy was a cultural shift from confrontational to collaborative upplier elationihips Tony commened an his e ment of Fond's curtent upply chain strategy "We have *problem wite the bosines model in this indistry. It is net working effectively for our soppliers I is not wock- ing elfectively for us. When my day i dominated by TAses related to financally distressed sappliers. com modity price shocks, quality problemis and conts sun, A's clear so me that there init be a better approsch. ABF sargeted companywide cost reductions of 10 percent of Ford's annual spend of production parts by 2010-57 hillion per year-by adopting what Tony considered best practices approach lo supply chain munagement and supplier partnerships "t's an envi- roment hetween Ferd and a select family of suppliers where innovative ideas can emerge, and then be incu- bated, evaluated and incorpocated into our products Under the new system, preferred suppliers would be matched with Ford purchasing and engineering manag- ers to work on projects to achieve quality, cost, and de livery goals. The 20 key elements of the ABF that Tony planned to propose are provided in Exhibit 1, which Brown described as "a kinder, gentler era of coopera- tion from global suppliers that can be implemented be- yond North America EXHIBIT 1 Key Elements of ABF Ford Commitments Bilateral Commitments Supplier Commitments Achieve best-in-class quality Data transparency Agree on detailed cost models Focus on total costs, included elimination of emphasis on bins Competitive cost at Job no. 1, with less emphasis on year- over-year price reductions Share current financial data to demonstrate health Backstop other commodity suppliers Marage and assure proper working conditions in their facilities and in the facilities of sub-tiers Sourcing of minority- and women-owned suppliers Use mutually agreeable multi- party agreement in directed tier 2 sourcing scenarios Technological innovations will be provided to Ford - Up-front reimbursement of supplier engineering, design and testing Long-term sourcing Improved comimonaity and reuse Improved product, cycle plan, and forecast volume stability Sharing of forecast volumes and . Open collaboration on global product plans (beyond 3 years) More disciplined program ex- ecution through Ford Global Product Development system manufacturing, engineering footprint Ongoing senior leadership communication Data exchange remains confidential www.ford.com/aboutfordmicrosites/sustainability-report-2006-07 "Stundra, "Ford Has a Better idea, p 49 Ibid. id. * Presentation by Tony Brown, October 7, 2005, www.oesa orgiemspagesigetAtch php?id=180 Chapter 2 Supply Strategy 43 Tony was proposing thut in the finst phise of the ARF iniplememation, his supply organization would focs on 20 high-impac commodity groups, vach an seats, tines and bumpers where the automaker spent approsimatety 535 billon per yen with 200 suppliers The plan was reduce the munher of suppliers for these cmmodities to 100 by the 2009 model year In the long tem. Tony's ohjective was to drink the production supply hane from 2.500 o 1000 from greter callaborution, udy supplier nvolvemem in new producr development, and pplier inovation How WIild the adseciuned costa and benefits be easued and shared among Ford and ts uppliens Font had u decades-long teadition of contrommational relationships with its supplier community, A rocent wir- vey of North American utomotie tier 1 suppliers tanked Font secondto last with a score of 157 verss tiranked Toyota at 415 and Honda a 175 (cale 500 =very good, 0very poor." Tuming around relutionships with aap- pliers could uke yeurs. Civen the difficult times in the industry and at Ford. Tony knew that Bill Ford would have questions about supplier skepticism reganding the company's metivations behind ABF and how quckly the plun would start to show results Tony Brown believed that it was neceisary to make major changes to Ford's supply chain if the company was going to survive Av he got ready for his meeting with Mr. Ford, Tony pondered how he should proceed with implementatisn, and specifically how suppliers could be convinced to biy into the principles of ABF. Tony com mented on the chullenges that ABF presented:This is no business as usual We're not only asking sur suppliers to iep up. We're aso asking ourselves to step up. FINALIZING THE PLAN Tony recognized that there would be a great many ques tions from other Ford executives, members of his par- chasing organization and suppliers regarding bow ABF would be implemented There were obviously going to be winners and losers from the esisting Ford supplier com munity under ABF and many of Ford's existing suppliers would have to be told that they would not be participating in future prograns The prefemed suppliers would have many questions regarding how their relationships would function with Ford in the future. For example. it was ex- pected that suppliers would benefit from hugher capacity utilization as a resalt of the inereased production vol umes. Furthermore, adkditional benefits were anticipated Read Case #2-3 found on page 42 of your text. Discuss in detail why it is important for an international company like Ford to implement an integrated supply chain. Consider the impact on the overall supply chain, international ramifications and the potential cost of failure in this endeavor. Post your response below using a minimum 300 words. Chapt e2 Supply Strategy 41 for energy, raw material, nd labor every quarter based on the cunent SsO 00 price per pound. Since Ray Soles had been able so biy almost all of Sabor's needs on uartery, enaanmual, or antual contacta he was o paticulay kee m depaning fnum his current supply prictice He had heard some nmos thut in a few years a mach lower-cost substinute for marcol mght be developed. He snpected that therefore, his current supplies were ansion to te Sabor t a long serm commitment Wartom Inc proposed a twoyear coract for 10000 pounds cach year with similar price provisions to those of Bilt Chemical G.K. Specialties uggeted an agreement for 125 per cent of Sabor's annal requiresens, which conld be dropped any time by eitber paty, bat which proposed a price of S56.00 for the current vear, to he adisted semianaally. thereafter based on inflation, energy, labor, and material Although Ray Soles did not know much about the actal manufacturine process for manconil, he had bcard that increases in capacity were expensive He also under- stood that two of the three componen raw materials for marconil were by-products from industrial processes that were reasonably stable. APRIL 15 On April 15, the Bih Chemical sales representative sent an e-mail to Ray Soles requesting a meeting on April 22. The e-mail conchaded, I woold like to bring my sales manager so that we may discuss our proposal for the marconil with you We will not be able to guarantee you supply after Auguit 1.f you are unable to commit." Case 2-3 Ford Motor Company: Aligned Business Framework? Tony Brown, senior vice president of global sourcing at Ford Motor Company (Ford), was putting the finish ing touches on his plan for the company's new sapply chain strategy"Aligned Business Framework" (ABF) ABF was a bold step that would significandy change the relationships between Ford and its soppliers. Tony described his motivation: "We want to operate a supply chain management system that delivers on the dimen- sions of quality, technology, delivery and cost, while executing programs in a disciplined fashion with faster time-to-marker." It was August 10, 2005, and Tony was expected to ne- view the final details of his proposal with company chair man and CEO William Clay (Bill) Ford Jr before making a formal public announcement the following month. ABF would substantially reduce the number of suppliers and give those that remained long lerm contracts and early involve ment in new product development programs. Tony expected that the strategy would provide benefits to Ford through overall lower costs, while suppliers would benefit from long-term tinuncial stability and profitability. The question remained, however, how he would ovince Ford's supplier community to commit to the principles of ABF. FORD MOTOR COMPANY Founded in 1903, Ford was the no. 2 U.S, automaker with global sales of approximately S177 billion In 2005, its global brands included Ford, Lincoln, Mercury, Jaguar. Land Rover, Aston Martin, and Volvo. In recent years all of the "Detroit 3" (General Motors. Ford. and Chrysler automakers were struggling under intense global com- petition, rising tuel prices, and steep product discounts and rebates. In the most recent quaiter, Ford reported a SL1 billion operating loss and the company's debt had recently been downgraded to junk-bond status. To turn around company performance, Ford had announced plans to cut its salaried workforce, reduce capacity by closing plants and selling the Hertz rental car division, and ramp up production of hybrid vehicles. This case has been written on the basis of published sources only. Consequenitly, the interpretation and perspectives presented in this case are not necessarily those of Ford Motor Compary or any of its employees Tom Stundza, "Ford Has a Better idea," Purchasing 135, no 12 (2006). p. 49 Ford Motor Company 2005 annual report Jeffrey McCracken, "Ford Retools Seeks Big Savings by Shaking Up Parts Supply System, The Globe & Mail, September 29,. 2005, p. B19. 42 Purchasing and Supply Management ALIGNED BUSINESS FRAMEWORK (ABF) The Ford global sopply chain included approsimanely 2500 prodoction and 9000 nongroduction suppliers, with operations in more than 60 countries, suoponing 107 Ford manufacturing sites. Total porchanes in 2005 were more than $90 billioe for roughly 25o production commodi ties (eg. seats, heating and cooling systems, addvanced electronies and steering systems) and S00 nonproduc- tion commodities ieg. health care, software, logistics and marketing and advertising services). The more than 130.000 active production parns accounted for approxi mutely S70 billion of total annoal purchases Historically Ford leaned heavily on soppliers for annual across-the-board price reductiens that averaged approximately 3 percent, although requests for more substantial reductions were commonplace. This environ- ment had created contemptuous relationships between Ford and its suppliers, which were reinforced through annual performmance evaluations and bonuses for buyers based on achieving year-over-year price reduction ob- jectives. The foundation of the new ABF strategy was a cultural shift from confrontational to collaborative upplier elationihips Tony commened an his e ment of Fond's curtent upply chain strategy "We have *problem wite the bosines model in this indistry. It is net working effectively for our soppliers I is not wock- ing elfectively for us. When my day i dominated by TAses related to financally distressed sappliers. com modity price shocks, quality problemis and conts sun, A's clear so me that there init be a better approsch. ABF sargeted companywide cost reductions of 10 percent of Ford's annual spend of production parts by 2010-57 hillion per year-by adopting what Tony considered best practices approach lo supply chain munagement and supplier partnerships "t's an envi- roment hetween Ferd and a select family of suppliers where innovative ideas can emerge, and then be incu- bated, evaluated and incorpocated into our products Under the new system, preferred suppliers would be matched with Ford purchasing and engineering manag- ers to work on projects to achieve quality, cost, and de livery goals. The 20 key elements of the ABF that Tony planned to propose are provided in Exhibit 1, which Brown described as "a kinder, gentler era of coopera- tion from global suppliers that can be implemented be- yond North America EXHIBIT 1 Key Elements of ABF Ford Commitments Bilateral Commitments Supplier Commitments Achieve best-in-class quality Data transparency Agree on detailed cost models Focus on total costs, included elimination of emphasis on bins Competitive cost at Job no. 1, with less emphasis on year- over-year price reductions Share current financial data to demonstrate health Backstop other commodity suppliers Marage and assure proper working conditions in their facilities and in the facilities of sub-tiers Sourcing of minority- and women-owned suppliers Use mutually agreeable multi- party agreement in directed tier 2 sourcing scenarios Technological innovations will be provided to Ford - Up-front reimbursement of supplier engineering, design and testing Long-term sourcing Improved comimonaity and reuse Improved product, cycle plan, and forecast volume stability Sharing of forecast volumes and . Open collaboration on global product plans (beyond 3 years) More disciplined program ex- ecution through Ford Global Product Development system manufacturing, engineering footprint Ongoing senior leadership communication Data exchange remains confidential www.ford.com/aboutfordmicrosites/sustainability-report-2006-07 "Stundra, "Ford Has a Better idea, p 49 Ibid. id. * Presentation by Tony Brown, October 7, 2005, www.oesa orgiemspagesigetAtch php?id=180 Chapter 2 Supply Strategy 43 Tony was proposing thut in the finst phise of the ARF iniplememation, his supply organization would focs on 20 high-impac commodity groups, vach an seats, tines and bumpers where the automaker spent approsimatety 535 billon per yen with 200 suppliers The plan was reduce the munher of suppliers for these cmmodities to 100 by the 2009 model year In the long tem. Tony's ohjective was to drink the production supply hane from 2.500 o 1000 from greter callaborution, udy supplier nvolvemem in new producr development, and pplier inovation How WIild the adseciuned costa and benefits be easued and shared among Ford and ts uppliens Font had u decades-long teadition of contrommational relationships with its supplier community, A rocent wir- vey of North American utomotie tier 1 suppliers tanked Font secondto last with a score of 157 verss tiranked Toyota at 415 and Honda a 175 (cale 500 =very good, 0very poor." Tuming around relutionships with aap- pliers could uke yeurs. Civen the difficult times in the industry and at Ford. Tony knew that Bill Ford would have questions about supplier skepticism reganding the company's metivations behind ABF and how quckly the plun would start to show results Tony Brown believed that it was neceisary to make major changes to Ford's supply chain if the company was going to survive Av he got ready for his meeting with Mr. Ford, Tony pondered how he should proceed with implementatisn, and specifically how suppliers could be convinced to biy into the principles of ABF. Tony com mented on the chullenges that ABF presented:This is no business as usual We're not only asking sur suppliers to iep up. We're aso asking ourselves to step up. FINALIZING THE PLAN Tony recognized that there would be a great many ques tions from other Ford executives, members of his par- chasing organization and suppliers regarding bow ABF would be implemented There were obviously going to be winners and losers from the esisting Ford supplier com munity under ABF and many of Ford's existing suppliers would have to be told that they would not be participating in future prograns The prefemed suppliers would have many questions regarding how their relationships would function with Ford in the future. For example. it was ex- pected that suppliers would benefit from hugher capacity utilization as a resalt of the inereased production vol umes. Furthermore, adkditional benefits were anticipated

Step by Step Solution

★★★★★

3.40 Rating (150 Votes )

There are 3 Steps involved in it

Step: 1

Answers Ans 1 Implementing the ABF approach is about having the CEO on board first and convincing hi...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started