Question

Topic Summary= Clean O2 was the first company to create a carbon capture unit that could fit into a commercial building. They call that unit

Topic Summary= Clean O2 was the first company to create a carbon capture unit that could fit into a commercial building. They call that unit the Carbin-X, which can absorb the equivalent of 300 trees. Thats 6 to 8 tons of carbon every year. To do this, the Carbin-X contains a reaction chamber that uses waste flue gas to recover CO2. Then, carbonate is created by combining the gas with a carbon-reduction chemical. The heat created by the machine is then used to heat the water that enters the buildings water tanks, so nothing goes to waste.

With this captured carbon, Clean O2 makes soap. They convert the carbon into Potassium Carbonate (also known as Pearl Ash) a common, safe chemical thats found in most soaps. The soaps are locally handmade, biodegradable, and 100% safe.

Subject= Process instrumentation and instrumental analysis.

Course= Chemical Engineering

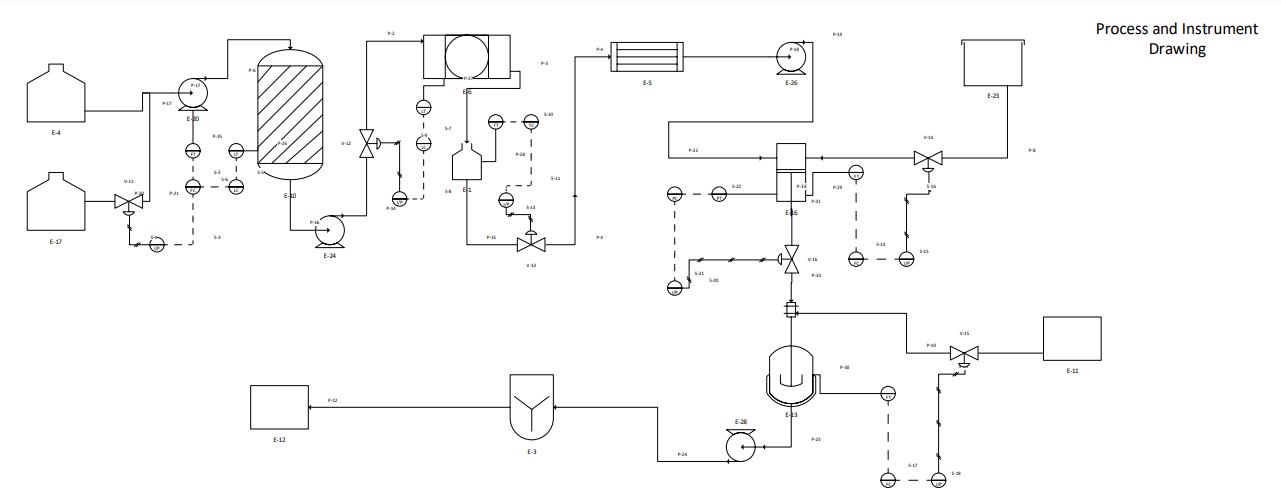

Question= Justify the design and control loops of the PID Diagram.

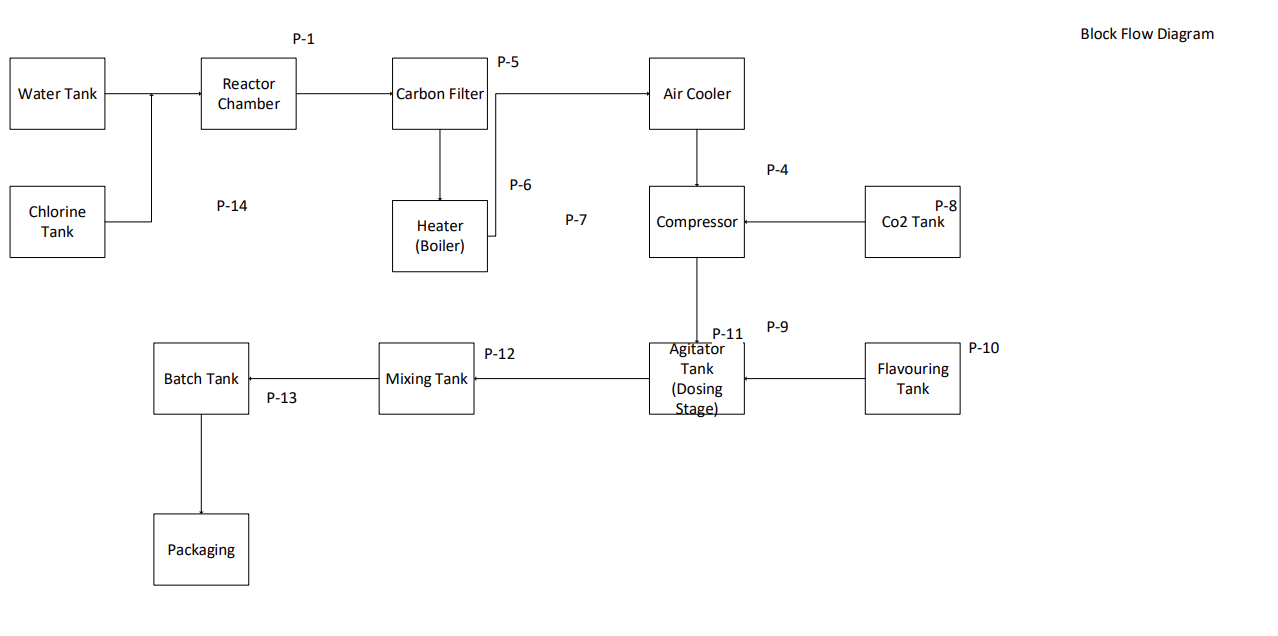

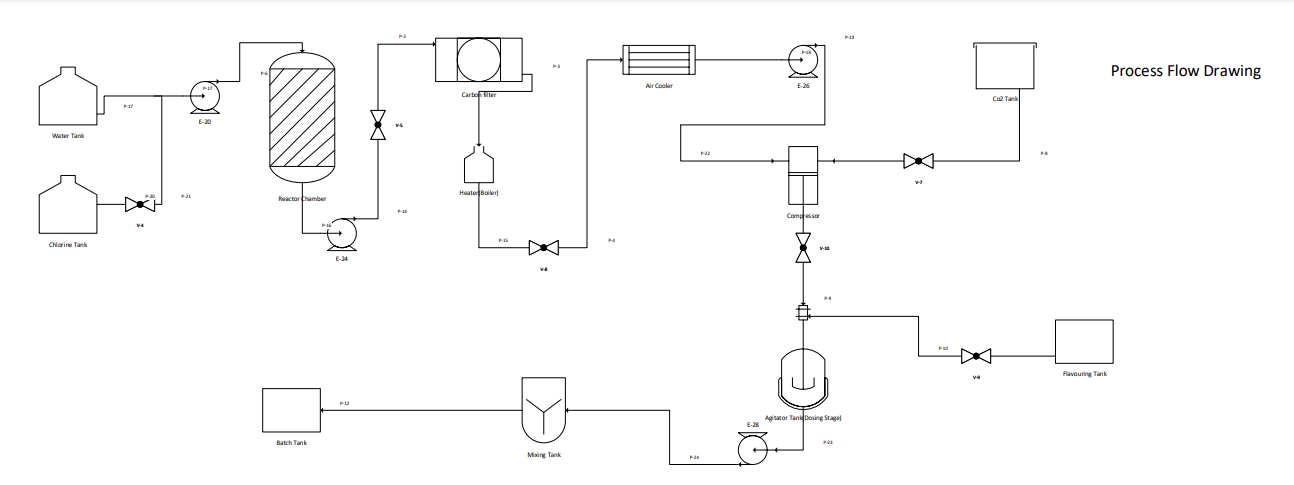

P-1 Block Flow Diagram P-5 Water Tank Reactor Chamber Carbon Filter Air Cooler P-4 P-6 P-14 Chlorine Tank P-7 P-8 Co2 Tank Compressor Heater (Boiler) P-9 P-10 P-12 Batch Tank Mixing Tank P-11 Agitator Tank (Dosing Stage) Flavouring Tank P-13 Packaging al Process Flow Drawing Air Cooler E36 Carter Co Tan Reactor Chamber Charine Tank E-24 Flavouring Tank Eutar Tantering Stage Batch Tank Mixing Tank Process and Instrument Drawing E-5 E26 5-12 E-11 Y 0 P-1 Block Flow Diagram P-5 Water Tank Reactor Chamber Carbon Filter Air Cooler P-4 P-6 P-14 Chlorine Tank P-7 P-8 Co2 Tank Compressor Heater (Boiler) P-9 P-10 P-12 Batch Tank Mixing Tank P-11 Agitator Tank (Dosing Stage) Flavouring Tank P-13 Packaging al Process Flow Drawing Air Cooler E36 Carter Co Tan Reactor Chamber Charine Tank E-24 Flavouring Tank Eutar Tantering Stage Batch Tank Mixing Tank Process and Instrument Drawing E-5 E26 5-12 E-11 Y 0

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started